A walking beam furnace offers precise temperature control with continuous movement of materials, ideal for uniform heating of heavy loads, while a pusher type furnace uses a pushing mechanism to move products through heated zones, suited for high-volume production with less emphasis on temperature uniformity. Choosing the right furnace depends on your specific production needs, balancing throughput, heating consistency, and material type.

Table of Comparison

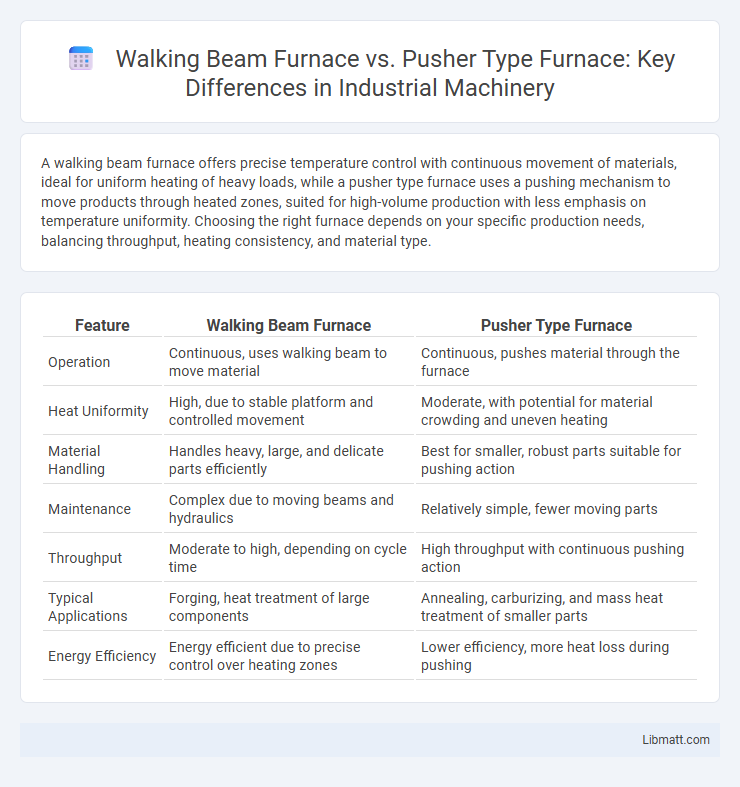

| Feature | Walking Beam Furnace | Pusher Type Furnace |

|---|---|---|

| Operation | Continuous, uses walking beam to move material | Continuous, pushes material through the furnace |

| Heat Uniformity | High, due to stable platform and controlled movement | Moderate, with potential for material crowding and uneven heating |

| Material Handling | Handles heavy, large, and delicate parts efficiently | Best for smaller, robust parts suitable for pushing action |

| Maintenance | Complex due to moving beams and hydraulics | Relatively simple, fewer moving parts |

| Throughput | Moderate to high, depending on cycle time | High throughput with continuous pushing action |

| Typical Applications | Forging, heat treatment of large components | Annealing, carburizing, and mass heat treatment of smaller parts |

| Energy Efficiency | Energy efficient due to precise control over heating zones | Lower efficiency, more heat loss during pushing |

Introduction to Industrial Heating Furnaces

Walking beam furnaces utilize stationary hearths with walking beams to transport metal slabs through controlled heating zones, optimizing heat uniformity and energy efficiency for steel reheating processes. Pusher type furnaces employ mechanical pushes to move slabs on a fixed hearth, enabling high throughput suitable for continuous production lines but with less precise temperature control. Both furnace types serve critical roles in steel manufacturing by providing consistent, high-temperature environments essential for material shaping and metallurgical transformations.

Overview of Walking Beam Furnaces

Walking beam furnaces utilize a series of interconnected beams to transport materials through the heating zone, ensuring uniform temperature distribution and efficient heat transfer. These furnaces are ideal for treating heavy steel slabs and forging billets due to their ability to maintain precise control over the material's movement. Compared to pusher type furnaces, walking beam furnaces offer better thermal uniformity and reduced material distortion, enhancing your process quality and energy efficiency.

Overview of Pusher Type Furnaces

Pusher type furnaces are continuous heat treatment systems where steel parts are pushed through multiple heating zones on a conveyor, ensuring uniform temperature distribution and consistent processing. These furnaces excel in high-volume production environments, offering precise control over atmosphere and temperature to enhance material properties like hardness and strength. Your choice of a pusher type furnace supports efficient, automated workflows critical for industries requiring steady throughput and repeatable results.

Key Differences in Furnace Design

Walking beam furnaces feature a mechanical beam that moves hot metal billets through the heating zone, providing uniform heat exposure and gentle handling, making them ideal for high-quality steel processing. Pusher type furnaces use a pusher mechanism to slide the billets forward on a skid bar or walking beam, offering higher throughput and simpler maintenance but potentially less uniform heating. The walking beam design excels in precision and reduced thermal stress, while pusher furnaces prioritize efficiency and cost-effectiveness in mass production.

Energy Efficiency Comparison

Walking beam furnaces typically offer higher energy efficiency due to their ability to closely control the temperature and atmosphere for each individual piece, reducing heat loss and improving fuel utilization. Pusher type furnaces tend to have higher thermal inertia and may experience more heat leakage because of continuous material movement, which can decrease overall efficiency. You can achieve better energy savings with a walking beam furnace, especially in processes requiring precise thermal profiles and minimal fuel consumption.

Product Quality and Temperature Uniformity

Walking beam furnaces provide superior temperature uniformity by transporting products on a series of linked beams, ensuring consistent heat exposure and enhancing product quality with minimal distortion or scaling. In contrast, pusher type furnaces move products through a pusher mechanism on a single plane, which can lead to less uniform temperature distribution and increased risk of surface defects. Therefore, walking beam furnaces are preferred for applications demanding high-quality finishes and precise thermal control.

Maintenance and Operational Costs

Walking beam furnaces typically incur lower maintenance costs due to simpler mechanical components and less wear on moving parts compared to pusher type furnaces, which often require frequent repairs for the push mechanism and rail systems. Operational costs for walking beam furnaces are generally reduced as they provide more consistent heat distribution, minimizing energy consumption and reducing scale formation on products. Pusher furnaces, while capable of higher throughput, tend to have increased energy usage and higher maintenance downtime, impacting overall operational efficiency.

Throughput and Flexibility

Walking beam furnaces offer higher throughput due to continuous, steady material movement, making them ideal for large-scale production of uniform loads. Pusher type furnaces provide greater operational flexibility by accommodating varied load sizes and mixed batch processing, allowing for customized heating cycles. The choice between the two depends on production volume needs and the complexity of the heating process.

Applications and Industry Suitability

Walking beam furnaces excel in applications requiring precise temperature control and uniform heating, making them ideal for processing large metal slabs and heavy-duty steel components in the steel manufacturing and forging industries. Pusher type furnaces are better suited for continuous production lines handling smaller castings, billets, or parts, commonly used in automotive, aluminum extrusion, and light metal industries due to their efficient throughput and versatility. Your choice depends on factors like product size, throughput requirements, and the desired level of thermal consistency for optimal production efficiency.

Choosing the Right Furnace for Your Needs

Walking beam furnaces offer precise temperature control and uniform heating, making them ideal for processing high-quality steel with minimal distortion. Pusher type furnaces excel in high-volume production, delivering continuous throughput and energy efficiency for heavy-duty industrial applications. Your choice should balance production capacity, material type, and desired heat treatment precision to optimize operational efficiency.

Walking beam furnace vs pusher type furnace Infographic

libmatt.com

libmatt.com