Gear drives provide precise motion control and high torque transmission with minimal slip, making them ideal for heavy-duty applications requiring accurate synchronization. Belt drives offer quieter operation and flexibility with shock absorption, better suited for lighter loads and systems where reduced maintenance and ease of installation are priorities for your machinery.

Table of Comparison

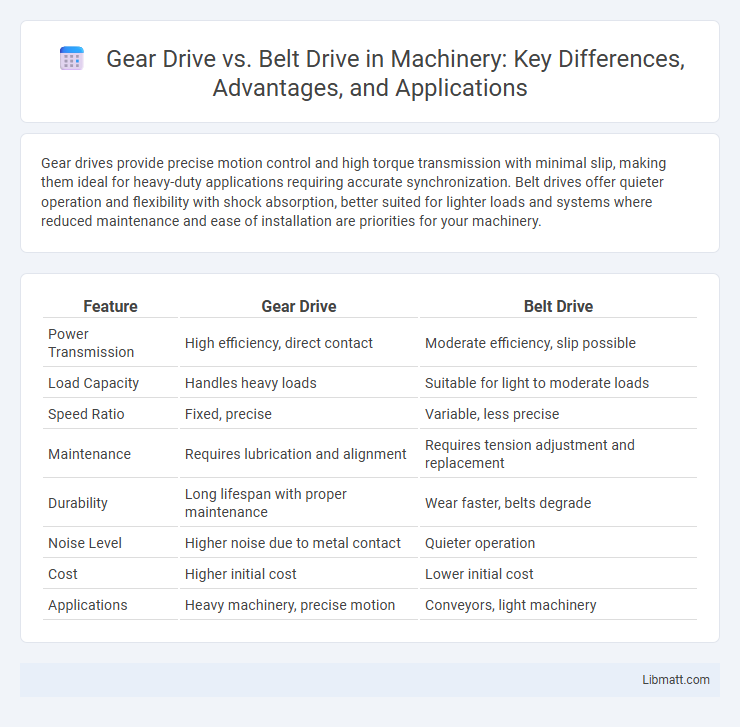

| Feature | Gear Drive | Belt Drive |

|---|---|---|

| Power Transmission | High efficiency, direct contact | Moderate efficiency, slip possible |

| Load Capacity | Handles heavy loads | Suitable for light to moderate loads |

| Speed Ratio | Fixed, precise | Variable, less precise |

| Maintenance | Requires lubrication and alignment | Requires tension adjustment and replacement |

| Durability | Long lifespan with proper maintenance | Wear faster, belts degrade |

| Noise Level | Higher noise due to metal contact | Quieter operation |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Heavy machinery, precise motion | Conveyors, light machinery |

Introduction to Gear Drive and Belt Drive

Gear drives use interlocking teeth on gears to transmit torque and power with precise speed ratios and high efficiency, offering durability and minimal slip in mechanical systems. Belt drives rely on flexible belts running over pulleys to transfer motion and power quietly and smoothly, accommodating slight misalignments and providing shock absorption. Each drive system suits different industrial applications based on load capacity, maintenance needs, and operational speed requirements.

Key Differences Between Gear Drive and Belt Drive

Gear drive systems provide precise power transmission with high torque capacity and minimal slip due to direct meshing of gear teeth, making them ideal for heavy-duty applications. Belt drives, using flexible belts over pulleys, offer smoother operation, shock absorption, and cost-effectiveness but may suffer from slippage and lower torque limits. Your choice between gear drive and belt drive depends on factors like load requirements, maintenance preferences, and desired efficiency.

Working Principles of Gear Drives

Gear drives operate through the meshing of toothed wheels that transmit torque by direct contact, ensuring precise speed ratios and high power efficiency. The interlocking teeth enhance mechanical advantage by minimizing slip and enabling synchronous motion between shafts. These drives excel in applications demanding accurate positioning and consistent rotational speed under varying load conditions.

Working Principles of Belt Drives

Belt drives operate by transmitting power through a continuous loop of flexible material, typically rubber or synthetic fiber, that connects pulleys on separate shafts. The friction between the belt and pulleys allows rotational motion to transfer smoothly, accommodating misalignments and reducing noise and vibration. Your machinery benefits from belt drives with efficient speed variation and shock absorption, making them ideal for applications where flexibility and quiet operation are essential.

Efficiency Comparison: Gear Drive vs Belt Drive

Gear drives typically demonstrate higher efficiency rates, often exceeding 95%, due to direct metal-to-metal contact minimizing energy losses. Belt drives generally have lower efficiency, ranging from 85% to 95%, influenced by factors such as belt slip, stretch, and friction. The choice between gear and belt drive depends on the application's demand for precision, load capacity, and maintenance considerations.

Application Areas: Where Each System Excels

Gear drives excel in heavy-duty applications such as automotive transmissions, industrial machinery, and robotics due to their high torque capacity, precise motion control, and durability under high stress. Belt drives are preferred in lighter-duty settings like HVAC systems, agricultural equipment, and conveyor systems because they offer quieter operation, shock absorption, and easier maintenance. Each system's design parameters make it ideal for either high-power transmission with minimal backlash or cost-effective power transfer with flexible alignment.

Maintenance and Durability Considerations

Gear drives require regular lubrication and inspection to maintain optimal performance, while belt drives need periodic tension adjustments and replacement due to wear. Gear drives generally offer greater durability and can handle higher loads and harsh environments compared to belt drives, which are more prone to slippage and material degradation over time. Your choice should consider the maintenance frequency and durability requirements of your specific application.

Noise and Vibration: Which is Quieter?

Gear drives typically generate more noise and vibration due to metal-to-metal contact and gear tooth impacts, making them louder in operation. Belt drives use flexible belts that absorb shocks and dampen vibrations, resulting in quieter and smoother performance. For applications requiring minimal noise, belt drives are generally the preferred choice over gear drives.

Cost Analysis: Initial and Long-term Expenses

Gear drives typically involve higher initial costs due to precise manufacturing and material requirements, whereas belt drives offer lower upfront expenses with simpler components. Over the long term, gear drives often incur reduced maintenance costs and increased durability, while belt drives may face frequent replacements and tension adjustments, leading to higher cumulative expenses. Evaluating total cost of ownership depends on application-specific factors such as load, speed, and environmental conditions impacting wear and efficiency.

Choosing the Right Drive System for Your Needs

Gear drives offer high torque transmission with precise speed control, making them ideal for heavy-duty applications requiring durability and minimal slippage. Belt drives provide quieter operation and flexibility in power transmission over longer distances, suitable for lighter loads and shock absorption. Selecting the right drive system depends on factors like load requirements, desired speed ratio, maintenance preferences, and environmental conditions.

Gear drive vs belt drive Infographic

libmatt.com

libmatt.com