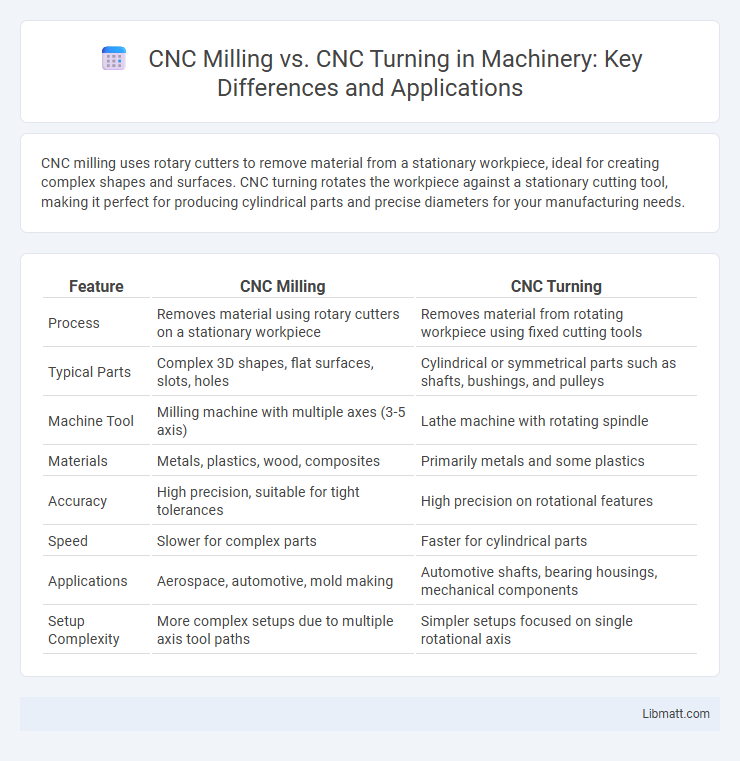

CNC milling uses rotary cutters to remove material from a stationary workpiece, ideal for creating complex shapes and surfaces. CNC turning rotates the workpiece against a stationary cutting tool, making it perfect for producing cylindrical parts and precise diameters for your manufacturing needs.

Table of Comparison

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Process | Removes material using rotary cutters on a stationary workpiece | Removes material from rotating workpiece using fixed cutting tools |

| Typical Parts | Complex 3D shapes, flat surfaces, slots, holes | Cylindrical or symmetrical parts such as shafts, bushings, and pulleys |

| Machine Tool | Milling machine with multiple axes (3-5 axis) | Lathe machine with rotating spindle |

| Materials | Metals, plastics, wood, composites | Primarily metals and some plastics |

| Accuracy | High precision, suitable for tight tolerances | High precision on rotational features |

| Speed | Slower for complex parts | Faster for cylindrical parts |

| Applications | Aerospace, automotive, mold making | Automotive shafts, bearing housings, mechanical components |

| Setup Complexity | More complex setups due to multiple axis tool paths | Simpler setups focused on single rotational axis |

Introduction to CNC Milling and CNC Turning

CNC milling involves removing material from a workpiece using rotary cutters to create complex shapes and features with high precision, making it ideal for producing parts with intricate geometries. CNC turning uses a rotating workpiece held in a chuck, where a cutting tool moves linearly to shape the material, primarily producing cylindrical or symmetrical components. Both processes are essential in manufacturing, with CNC milling excelling at multi-axis machining and CNC turning optimized for efficient production of round parts.

Core Principles of CNC Milling

CNC milling operates by rotating multi-axis cutting tools to remove material from a stationary workpiece, enabling complex shapes and precision features with high tolerances. It excels in creating intricate parts through versatile tool paths, including contouring, drilling, and slotting, driven by computer numerical control. Understanding these core principles helps optimize your machining processes for efficiency and accuracy in production.

Core Principles of CNC Turning

CNC turning operates by rotating the workpiece on a spindle while a cutting tool moves linearly to remove material, producing cylindrical parts with high precision. This process excels at creating symmetrical shapes such as shafts, bushings, and threaded components by controlling tool paths along specific axes. The core principles include precise spindle rotation speed, tool positioning, and feed rate to achieve accurate, repeatable cuts on round stock materials.

Key Differences Between CNC Milling and CNC Turning

CNC milling involves removing material from a stationary workpiece using rotating cutting tools, making it ideal for producing complex shapes with precise contours and multiple surface features. CNC turning rotates the workpiece against a stationary cutting tool, primarily used for creating cylindrical parts with consistent diameters and smooth finishes. Your choice between these processes depends on the geometry and complexity of the part, with milling offering versatility for 3D shapes and turning excelling in high-precision rotational components.

Applications of CNC Milling

CNC milling is ideal for producing complex parts with intricate shapes, featuring precise contouring and multi-axis machining capabilities, commonly used in aerospace, automotive, and medical device manufacturing. Its versatility allows for cutting materials such as aluminum, steel, and plastics to create components like engine blocks, molds, and custom prototypes. Your production benefits from CNC milling's ability to handle both simple and highly detailed tasks, making it essential for custom and high-precision applications.

Applications of CNC Turning

CNC turning is primarily used for manufacturing cylindrical or rotational parts such as shafts, pins, and bushings. This process is ideal for creating precise, symmetrical components in industries like automotive, aerospace, and medical devices, where consistent surface finish and tight tolerances are essential. Your production efficiency increases when utilizing CNC turning for high-volume runs of complex, round geometries that require minimal post-processing.

Material Compatibility: Milling vs Turning

CNC milling excels in processing a wide range of materials including metals, plastics, and composites due to its multi-axis cutting capabilities, enabling complex shapes and fine details. CNC turning is highly effective for cylindrical parts, working best with materials such as steel, aluminum, brass, and certain plastics, focusing on rotational symmetry. Choosing between milling and turning depends on your material type and part geometry, ensuring optimal machining efficiency and quality.

Surface Finish and Accuracy Comparison

CNC milling typically offers superior surface finish and higher accuracy for complex geometries due to its multi-axis capabilities and precise tool control, allowing for intricate detailing and finer tolerances. CNC turning excels in achieving excellent surface finish and dimensional accuracy on cylindrical or symmetrical parts, utilizing high spindle speeds and rigid tool setups for consistent concentricity. The choice between CNC milling and turning depends on part design, with milling favored for intricate shapes requiring detailed surface finishes and turning preferred for precision in round components.

Cost Considerations for CNC Milling and Turning

CNC milling typically incurs higher costs due to longer setup times and more complex tooling requirements compared to CNC turning, which generally offers faster cycle times and lower labor expenses for producing cylindrical parts. Tool wear and material removal rates also influence overall costs, with turning being more economical for high-volume production of rotational components. You should evaluate these factors alongside part geometry and volume to determine the most cost-effective machining method.

Choosing the Right Process for Your Project

CNC milling offers precise, multi-axis machining ideal for complex shapes and detailed geometries, while CNC turning excels in creating symmetrical cylindrical parts with high speed and efficiency. Selecting the right process depends on the project's design specifications, material type, and production volume, ensuring optimal accuracy and cost-effectiveness. Understanding these differences helps manufacturers deliver superior components tailored to specific engineering requirements.

CNC milling vs CNC turning Infographic

libmatt.com

libmatt.com