Gravity conveyors rely on the force of gravity to move items, making them energy-efficient and ideal for simple, low-cost transfer of goods. Powered conveyors use motors to control speed and direction, offering greater flexibility and automation for handling heavier or more complex loads in your material handling system.

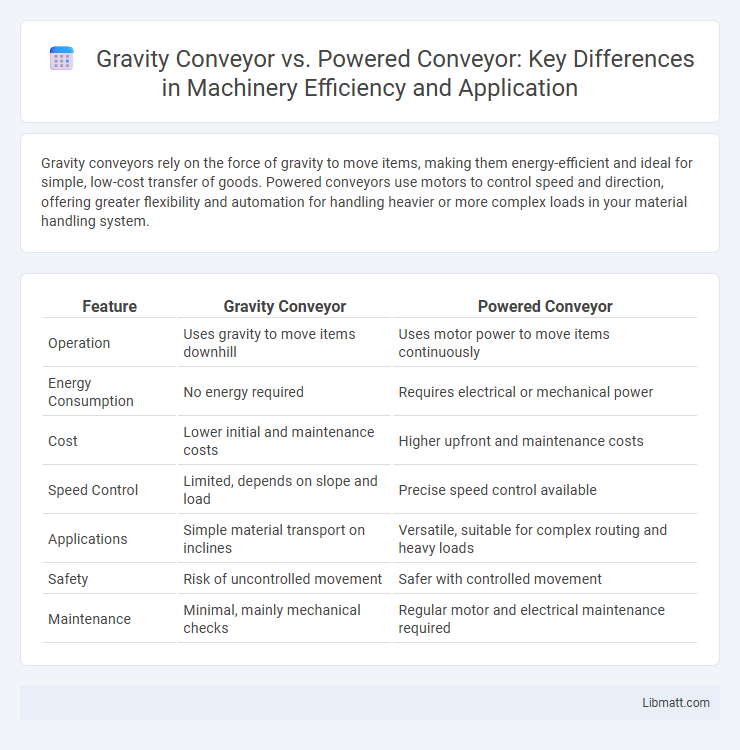

Table of Comparison

| Feature | Gravity Conveyor | Powered Conveyor |

|---|---|---|

| Operation | Uses gravity to move items downhill | Uses motor power to move items continuously |

| Energy Consumption | No energy required | Requires electrical or mechanical power |

| Cost | Lower initial and maintenance costs | Higher upfront and maintenance costs |

| Speed Control | Limited, depends on slope and load | Precise speed control available |

| Applications | Simple material transport on inclines | Versatile, suitable for complex routing and heavy loads |

| Safety | Risk of uncontrolled movement | Safer with controlled movement |

| Maintenance | Minimal, mainly mechanical checks | Regular motor and electrical maintenance required |

Introduction to Conveyor Systems

Gravity conveyors use the force of gravity to move materials along a slight decline, requiring no external power source, making them energy-efficient and low-maintenance. Powered conveyors utilize motors to control material movement, offering greater speed, direction control, and the ability to handle heavier or more complex loads. Your choice between gravity and powered conveyor systems depends on factors like load weight, facility layout, and operational requirements.

What is a Gravity Conveyor?

A gravity conveyor is a type of conveyor system that relies on gravity to move materials along a slight decline without the need for motorized power, making it energy-efficient and low maintenance. Unlike powered conveyors, gravity conveyors are ideal for transporting lighter loads or when precise speed control is not critical. Your choice depends on factors such as load weight, movement control, and energy consumption requirements.

What is a Powered Conveyor?

A powered conveyor is a motor-driven system designed to move materials efficiently along a predetermined path, using belts, rollers, or chains to transport goods. Unlike gravity conveyors, which rely on slope and force of gravity, powered conveyors provide consistent speed and control, enhancing productivity in various industries. Your choice of a powered conveyor ensures precise handling and integration with automated processes for optimized material flow.

Key Components of Gravity vs Powered Conveyors

Gravity conveyors consist primarily of rollers or skate wheels mounted on a metal frame, relying on the force of gravity to move items, while powered conveyors include motors, belts or chains, and control systems to actively propel materials. Key components of gravity conveyors are the rollers, frames, and supports, offering simplicity and low maintenance for sloped or manual flow applications. Powered conveyors feature drive motors, belts or chains, pulleys, and variable speed controls, enabling precise movement and automation in complex material handling systems.

Advantages of Gravity Conveyors

Gravity conveyors offer significant energy savings since they do not require electrical power, making them highly cost-effective for material transport. Their simple design ensures low maintenance and easy installation, reducing downtime and operational expenses. You benefit from increased reliability and flexibility in handling varying loads without complex mechanical components.

Advantages of Powered Conveyors

Powered conveyors offer precise control over item movement speed and direction, enhancing efficiency in complex material handling systems. They support heavier loads and can operate continuously, reducing manual labor and increasing throughput. Your operation benefits from improved automation capabilities and reduced risk of product damage compared to gravity conveyors.

Limitations of Gravity and Powered Conveyors

Gravity conveyors are limited by their reliance on slope and manual force, making them unsuitable for heavy loads or long distances where consistent movement is required. Powered conveyors, while capable of handling heavier and more complex materials, face limitations in terms of higher energy consumption, increased maintenance requirements, and potential operational downtime due to motor or electrical failures. Both systems have constraints related to scalability, with gravity conveyors restricted by physical incline and powered conveyors by power supply and mechanical wear.

Ideal Applications for Each Conveyor Type

Gravity conveyors are ideal for applications involving lightweight, non-sensitive items that can move by natural force such as packaging, sorting, and assembly lines with slight inclination. Powered conveyors suit environments requiring precise control over movement, including heavy loads, long distances, or inclined surfaces in industries like automotive manufacturing, warehousing, and distribution centers. These conveyors support continuous flow and automated handling systems where consistent speed and direction are critical.

Cost Comparison: Gravity vs Powered Conveyors

Gravity conveyors typically incur lower initial investment and minimal operational costs due to their passive design, relying on gravity instead of motors. Powered conveyors involve higher upfront expenses and ongoing energy costs for motors and maintenance, making them more expensive over time. Cost efficiency favors gravity conveyors for light loads and simple transport, while powered conveyors justify their price with increased control and automation capabilities.

How to Choose the Right Conveyor for Your Needs

Selecting the right conveyor depends on factors such as load weight, speed requirements, and energy consumption. Gravity conveyors are ideal for lightweight, low-maintenance applications with minimal energy use, relying on gravity for movement. Powered conveyors suit heavier loads and precise speed control needs, offering consistent operation but higher power costs and maintenance.

Gravity conveyor vs powered conveyor Infographic

libmatt.com

libmatt.com