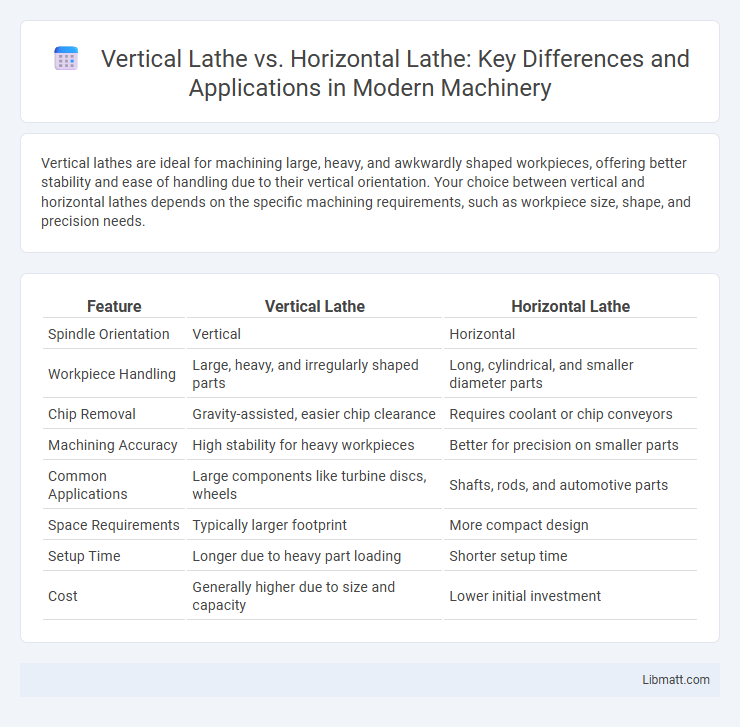

Vertical lathes are ideal for machining large, heavy, and awkwardly shaped workpieces, offering better stability and ease of handling due to their vertical orientation. Your choice between vertical and horizontal lathes depends on the specific machining requirements, such as workpiece size, shape, and precision needs.

Table of Comparison

| Feature | Vertical Lathe | Horizontal Lathe |

|---|---|---|

| Spindle Orientation | Vertical | Horizontal |

| Workpiece Handling | Large, heavy, and irregularly shaped parts | Long, cylindrical, and smaller diameter parts |

| Chip Removal | Gravity-assisted, easier chip clearance | Requires coolant or chip conveyors |

| Machining Accuracy | High stability for heavy workpieces | Better for precision on smaller parts |

| Common Applications | Large components like turbine discs, wheels | Shafts, rods, and automotive parts |

| Space Requirements | Typically larger footprint | More compact design |

| Setup Time | Longer due to heavy part loading | Shorter setup time |

| Cost | Generally higher due to size and capacity | Lower initial investment |

Introduction to Vertical and Horizontal Lathes

Vertical lathes feature a vertically oriented spindle allowing the workpiece to be mounted on a horizontal rotating table, ideal for machining large, heavy, and asymmetrical parts. Horizontal lathes utilize a horizontally aligned spindle where the workpiece is held between centers or in a chuck, making them suitable for turning long, cylindrical components with high precision. Both lathe types are essential in metalworking but differ significantly in setup, applications, and load handling capabilities.

Core Differences Between Vertical and Horizontal Lathes

Vertical lathes feature a vertically oriented spindle allowing workpieces to be mounted on a horizontal rotating table, ideal for large, heavy, and unevenly shaped components requiring stable support. Horizontal lathes have a horizontally aligned spindle where the workpiece is clamped between centers or held in a chuck for cylindrical or long parts, enabling precision turning and threading operations. Core differences include spindle orientation, workpiece positioning, and suitability for specific applications with vertical lathes better for heavy-duty, large-diameter parts and horizontal lathes optimized for long, slender components.

Advantages of Vertical Lathes

Vertical lathes offer significant advantages in machining large, heavy, or irregularly shaped workpieces due to their ability to support weight more effectively with lower gravitational distortion. Their design allows for easier loading and unloading of workpieces, improving operational efficiency and reducing downtime. If your machining tasks involve large diameters or require enhanced rigidity and precision, vertical lathes provide superior stability and cutting performance compared to horizontal lathes.

Advantages of Horizontal Lathes

Horizontal lathes offer precise machining of long and cylindrical workpieces due to their spindle axis being parallel to the ground, enhancing stability and reducing vibrations. Their design allows for easy loading and unloading of heavy parts, improving workflow efficiency in your manufacturing process. This makes horizontal lathes ideal for automotive, aerospace, and pipe-fitting industries requiring high accuracy and consistent surface finishes.

Typical Applications for Vertical Lathes

Vertical lathes are commonly utilized in industries requiring the machining of large, heavy, and awkwardly shaped workpieces such as aerospace components, automotive brake discs, and large valve bodies. Their design allows for the stable support of heavy parts with gravity aiding in precise machining processes, making them ideal for turning, boring, and facing operations on cylindrical or disc-shaped materials. These lathes excel in metalworking applications where high rigidity and accuracy are essential for large diameter machining.

Typical Applications for Horizontal Lathes

Horizontal lathes are commonly used in automotive, aerospace, and general manufacturing industries for machining long or cylindrical workpieces such as shafts, rods, and pipes. Their design allows for efficient turning, threading, and boring operations on components that require precision and consistency. Typical applications include producing engine parts, drive shafts, and large industrial rollers where accuracy and surface finish are critical.

Space Requirements and Footprint Comparison

Vertical lathes generally require less floor space compared to horizontal lathes due to their compact, upright design that optimizes vertical space utilization. Horizontal lathes have a larger footprint because their bed and workpiece extend horizontally, necessitating more clearance and room for operation. Evaluating your workshop's spatial constraints will help determine whether a vertical lathe's smaller footprint or a horizontal lathe's extended layout better suits your manufacturing environment.

Material Handling and Workpiece Size

Vertical lathes excel in handling large, heavy workpieces due to their robust, stable design and overhead crane compatibility, ideal for machining bulky materials like steel plates and large diameters. Horizontal lathes are better suited for elongated workpieces, offering efficient material handling through automatic bar feeders and tailstock supports for long shafts and pipes. The choice depends on workpiece size and weight, where vertical lathes optimize heavy, wide parts and horizontal lathes manage long, slender components.

Cost Considerations and Maintenance

Vertical lathes generally incur higher initial costs compared to horizontal lathes due to their specialized design and capability to handle larger, heavier workpieces. Maintenance for vertical lathes often demands more frequent alignment checks and lubrication because of their vertical spindle orientation, while horizontal lathes benefit from simpler access to components, reducing maintenance time and costs. Choosing between the two depends on budget constraints and long-term maintenance capabilities, with horizontal lathes typically offering lower operating expenses.

Choosing the Right Lathe for Your Workshop

Choosing the right lathe for your workshop depends on the size and type of workpieces, with vertical lathes ideal for heavy, large-diameter parts due to their stable vertical spindle and gravity-assisted chip removal. Horizontal lathes offer precision and versatility for longer, smaller-diameter components, featuring a horizontal spindle that supports a wide range of turning, facing, and threading operations. Consider factors like space, material handling, and machining precision to select between vertical lathes' robust design and horizontal lathes' adaptability.

Vertical lathe vs horizontal lathe Infographic

libmatt.com

libmatt.com