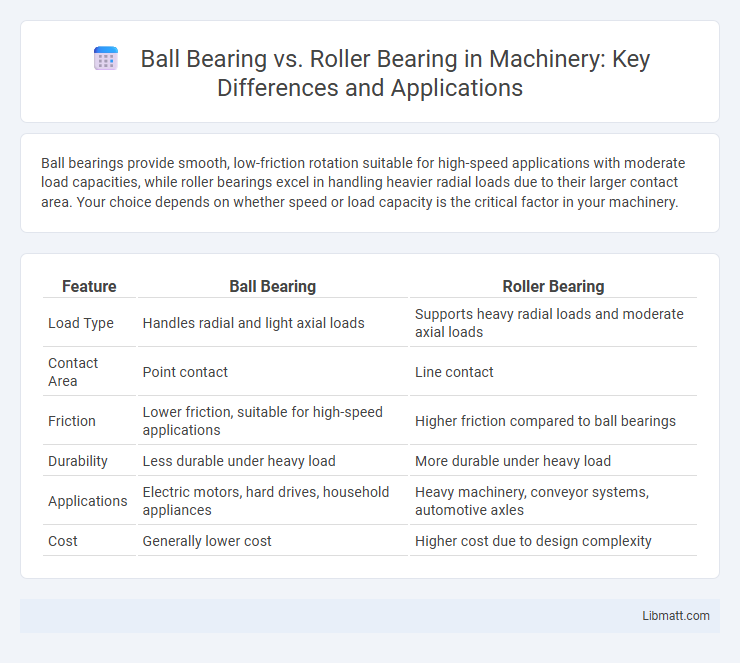

Ball bearings provide smooth, low-friction rotation suitable for high-speed applications with moderate load capacities, while roller bearings excel in handling heavier radial loads due to their larger contact area. Your choice depends on whether speed or load capacity is the critical factor in your machinery.

Table of Comparison

| Feature | Ball Bearing | Roller Bearing |

|---|---|---|

| Load Type | Handles radial and light axial loads | Supports heavy radial loads and moderate axial loads |

| Contact Area | Point contact | Line contact |

| Friction | Lower friction, suitable for high-speed applications | Higher friction compared to ball bearings |

| Durability | Less durable under heavy load | More durable under heavy load |

| Applications | Electric motors, hard drives, household appliances | Heavy machinery, conveyor systems, automotive axles |

| Cost | Generally lower cost | Higher cost due to design complexity |

Introduction to Ball Bearings and Roller Bearings

Ball bearings and roller bearings are essential components in mechanical systems, designed to reduce friction and support radial and axial loads. Ball bearings use spherical balls to maintain separation between bearing races, offering smooth motion and low friction, ideal for high-speed applications. Roller bearings utilize cylindrical or tapered rollers, providing greater load capacity and durability for heavy-duty and shock-loading environments, enhancing your machinery's performance and lifespan.

Fundamental Differences Between Ball and Roller Bearings

Ball bearings use spherical balls to maintain the separation between bearing races, offering low friction and handling moderate radial and axial loads. Roller bearings utilize cylindrical or tapered rollers, providing greater load capacity and better performance under heavy radial loads and shock loads. Your choice depends on load type and application, with ball bearings suited for high-speed, light-load conditions and roller bearings optimized for heavier, more robust demands.

Design and Construction: Ball Bearings vs Roller Bearings

Ball bearings feature spherical rolling elements that minimize friction and support both radial and axial loads, making them ideal for high-speed applications. Roller bearings utilize cylindrical or tapered rollers designed to handle heavier radial loads with greater contact area, offering enhanced load-carrying capacity in demanding conditions. Your choice between the two depends on the specific design requirements and the type of loads involved in your machinery.

Load Capacity: Comparing Ball and Roller Bearings

Roller bearings typically offer higher load capacity than ball bearings due to their larger contact area between rolling elements and raceways, effectively distributing loads and reducing stress. Ball bearings excel in handling radial and axial loads but are limited in supporting heavy radial loads compared to roller bearings, especially cylindrical or tapered types. Understanding these differences helps optimize bearing selection for applications demanding either high load capacity or precise rotational performance.

Application Suitability: Where Each Bearing Excels

Ball bearings excel in high-speed applications with lighter loads, commonly used in electric motors, bicycles, and precision instruments due to their low friction and smooth rotation. Roller bearings are ideal for heavy-load and shock-load applications such as conveyor belt rollers, automotive wheel hubs, and industrial machinery because they distribute loads over a larger surface area. Selecting between ball and roller bearings depends on specific operational demands including load capacity, speed, and environmental conditions.

Friction and Efficiency: Performance Insights

Ball bearings typically offer lower friction and higher efficiency at moderate loads and high speeds due to their point contact design. Roller bearings, with line contact, handle heavier loads and reduce friction under high radial loads but may generate more friction at high speeds. Understanding your application's load and speed requirements helps optimize performance by selecting the most efficient bearing type.

Durability and Maintenance Considerations

Ball bearings typically offer lower friction and higher speed capabilities but may wear faster under heavy loads compared to roller bearings, which provide superior durability due to their larger contact area distributing loads more evenly. Roller bearings require less frequent maintenance in high-load environments, as their design minimizes stress and reduces the risk of premature failure. Choosing between the two depends on load conditions and maintenance capabilities, with roller bearings preferred for heavy-duty applications demanding long-term reliability.

Cost Analysis: Ball Bearing vs Roller Bearing

Ball bearings generally cost less than roller bearings due to simpler design and lower material usage, making them a cost-effective choice for applications requiring moderate load support. Roller bearings, while pricier, offer superior load capacity and durability, which can reduce long-term maintenance and replacement expenses. Your selection should balance initial investment with performance needs to optimize overall cost efficiency.

Common Industries and Use Cases

Ball bearings are widely used in automotive, aerospace, and consumer electronics industries due to their ability to handle high-speed rotational movements with low friction. Roller bearings are preferred in heavy machinery, construction equipment, and conveyor belts where they accommodate higher radial loads and impact forces. Choosing the right bearing for your application ensures optimal performance and longevity in specific industrial conditions.

Choosing the Right Bearing for Your Application

Selecting the right bearing for your application depends on load type, speed, and durability requirements. Ball bearings excel in high-speed environments with lighter loads due to their low friction and smooth operation, while roller bearings are better suited for heavier radial loads and offer greater rigidity. Evaluating specific operational conditions, such as load direction and contamination levels, ensures optimal bearing performance and longevity.

Ball bearing vs roller bearing Infographic

libmatt.com

libmatt.com