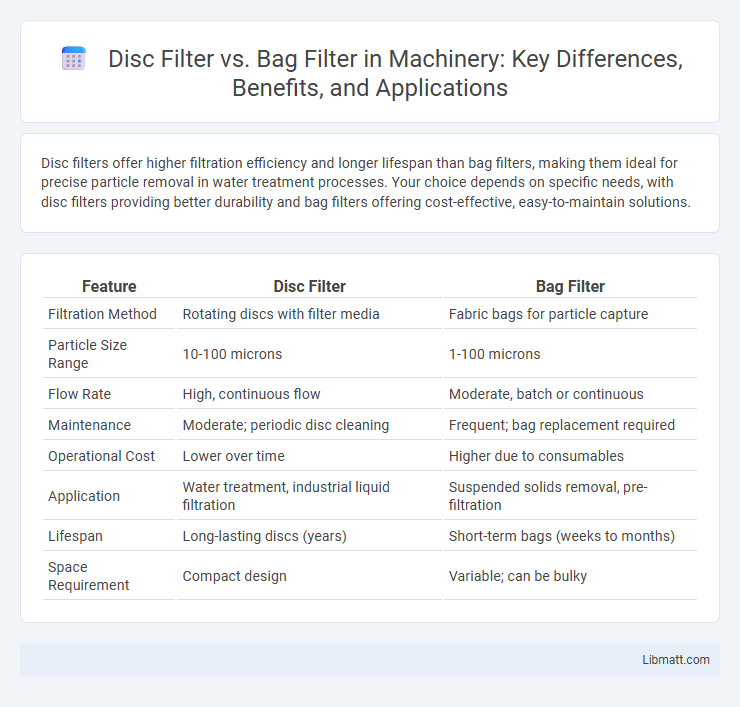

Disc filters offer higher filtration efficiency and longer lifespan than bag filters, making them ideal for precise particle removal in water treatment processes. Your choice depends on specific needs, with disc filters providing better durability and bag filters offering cost-effective, easy-to-maintain solutions.

Table of Comparison

| Feature | Disc Filter | Bag Filter |

|---|---|---|

| Filtration Method | Rotating discs with filter media | Fabric bags for particle capture |

| Particle Size Range | 10-100 microns | 1-100 microns |

| Flow Rate | High, continuous flow | Moderate, batch or continuous |

| Maintenance | Moderate; periodic disc cleaning | Frequent; bag replacement required |

| Operational Cost | Lower over time | Higher due to consumables |

| Application | Water treatment, industrial liquid filtration | Suspended solids removal, pre-filtration |

| Lifespan | Long-lasting discs (years) | Short-term bags (weeks to months) |

| Space Requirement | Compact design | Variable; can be bulky |

Introduction to Disc and Bag Filters

Disc filters utilize a series of grooved discs stacked together to trap contaminants, offering high filtration efficiency and reusable cleaning options. Bag filters employ fabric filter bags that capture particles as fluid passes through, providing versatile filtration suitable for various industrial applications. Both filters serve to remove suspended solids, but disc filters excel in continuous operation with lower maintenance, whereas bag filters are favored for ease of replacement and managing large volumes of debris.

How Disc Filters Work

Disc filters operate by passing water through a series of grooved discs stacked together, where contaminants are trapped in the grooves as water flows through. The filtration process involves both surface and depth filtration, enabling efficient removal of particles typically ranging from 10 to 100 microns. Their self-cleaning mechanism often includes backflushing, which dislodges trapped debris, ensuring consistent filtration performance and reduced maintenance compared to bag filters.

How Bag Filters Operate

Bag filters operate by capturing particles as fluid passes through a porous fabric, where contaminants are trapped on the surface or within the fibers. The filtration efficiency depends on the bag's material, pore size, and construction, making them suitable for removing various solids in liquids or gases. Your choice of bag filters can enhance system performance by providing effective sediment retention and easy maintenance.

Key Differences Between Disc and Bag Filters

Disc filters use multiple grooved discs to create filtration surfaces, allowing for efficient removal of fine particles and higher surface area compared to bag filters, which rely on a porous fabric bag to trap debris. Bag filters typically have lower flow rates and require more frequent replacement or cleaning due to clogging, whereas disc filters offer longer service intervals and easier backwashing capabilities. Your choice between these filters depends on factors like required filtration precision, maintenance preferences, and system flow rate requirements.

Filtration Efficiency Comparison

Disc filters provide higher filtration efficiency than bag filters due to their multilayer design, which captures finer particles down to 20 microns or less. Bag filters typically offer coarser filtration, ranging from 50 to 200 microns, making them more suitable for removing larger debris but less effective against small contaminants. Your choice depends on the required filtration precision and particulate size in your specific application.

Maintenance and Longevity

Disc filters require periodic backwashing and manual cleaning of the discs to maintain optimal performance, with replacement intervals typically spanning several years depending on water quality. Bag filters involve changing or cleaning the filter bags regularly, often more frequently than disc filters, resulting in simpler but more frequent maintenance routines. Disc filters generally offer longer lifespan and higher durability due to their sturdy construction and self-cleaning mechanism, whereas bag filters may wear out faster and require more frequent replacement.

Applications and Industries

Disc filters are widely used in water treatment, irrigation, and food processing industries due to their high filtration efficiency for fine particles and low maintenance requirements. Bag filters are preferred in chemical manufacturing, pharmaceuticals, and paint production where removal of larger solids and high dirt-holding capacity are essential. Both filtration systems serve critical roles in industrial waste management and process fluid purification, tailored to specific particle size removal and flow rate needs.

Cost Analysis: Disc Filter vs Bag Filter

Disc filters generally have higher initial costs due to complex design and materials but offer lower maintenance expenses and longer lifespan compared to bag filters. Bag filters present a cost-effective upfront investment but require frequent replacements and labor, increasing operating costs over time. Your choice depends on balancing upfront budget constraints with long-term operational savings and performance needs.

Environmental Impact and Waste Management

Disc filters typically generate less wastewater because of their efficient filtration process, reducing environmental impact compared to bag filters, which often require more frequent replacement and disposal of used bags. Waste management for disc filters is streamlined due to reusable filter media, whereas bag filters contribute to higher solid waste volumes requiring proper handling and disposal. Choosing disc filters can support more sustainable operations by minimizing waste and conserving water resources, benefiting your environmental footprint.

Choosing the Right Filter for Your Needs

Disc filters provide high filtration efficiency and are ideal for applications requiring fine particulate removal with low maintenance, making them suitable for irrigation and industrial water treatment. Bag filters offer simplicity and cost-effectiveness, excelling in handling large volumes of liquid with heavier particulate loads and easy replacement. Selecting between disc and bag filters depends on factors like filtration precision, flow rate, maintenance frequency, and budget constraints.

Disc filter vs bag filter Infographic

libmatt.com

libmatt.com