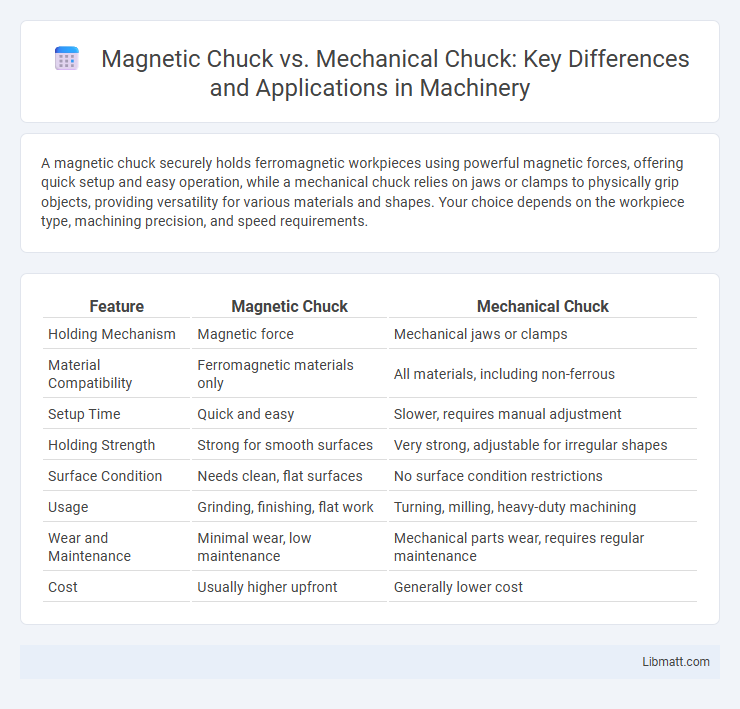

A magnetic chuck securely holds ferromagnetic workpieces using powerful magnetic forces, offering quick setup and easy operation, while a mechanical chuck relies on jaws or clamps to physically grip objects, providing versatility for various materials and shapes. Your choice depends on the workpiece type, machining precision, and speed requirements.

Table of Comparison

| Feature | Magnetic Chuck | Mechanical Chuck |

|---|---|---|

| Holding Mechanism | Magnetic force | Mechanical jaws or clamps |

| Material Compatibility | Ferromagnetic materials only | All materials, including non-ferrous |

| Setup Time | Quick and easy | Slower, requires manual adjustment |

| Holding Strength | Strong for smooth surfaces | Very strong, adjustable for irregular shapes |

| Surface Condition | Needs clean, flat surfaces | No surface condition restrictions |

| Usage | Grinding, finishing, flat work | Turning, milling, heavy-duty machining |

| Wear and Maintenance | Minimal wear, low maintenance | Mechanical parts wear, requires regular maintenance |

| Cost | Usually higher upfront | Generally lower cost |

Introduction to Magnetic and Mechanical Chucks

Magnetic chucks use powerful magnets to securely hold ferromagnetic workpieces during machining, offering quick setup and easy workpiece loading. Mechanical chucks rely on adjustable jaws or clamps to physically grip the workpiece, providing versatile holding for a wider range of materials and shapes. Your choice between these chucks depends on the specific application, material type, and machining precision required.

Key Differences Between Magnetic and Mechanical Chucks

Magnetic chucks use electromagnetic force to securely hold ferromagnetic workpieces, offering quick setup and no mechanical wear, making them ideal for flat or thin materials. Mechanical chucks rely on physical clamping mechanisms such as jaws or bolts to grip parts, providing strong hold for irregular shapes but requiring manual adjustment and more setup time. Your choice depends on the material type, shape, and machining precision, as magnetic chucks excel in speed and ease, while mechanical chucks ensure strong, versatile clamping.

How Magnetic Chucks Work

Magnetic chucks operate by generating a strong magnetic field that securely holds ferromagnetic workpieces during machining processes, using either permanent magnets or electromagnets. The magnetic force is evenly distributed across the chuck's surface, ensuring stable and precise workpiece positioning without physical clamps. This method enhances machining accuracy and reduces setup time compared to mechanical chucks, which rely on physical gripping mechanisms.

How Mechanical Chucks Operate

Mechanical chucks operate by using jaws that tighten around a workpiece through a manual or powered mechanism, typically involving a scroll plate that moves the jaws simultaneously when rotated. These chucks provide a strong grip on irregular or non-magnetic materials, making them versatile for various machining tasks. The precision and reliability in holding workpieces securely enable effective turning, milling, and drilling operations.

Advantages of Magnetic Chucks

Magnetic chucks provide superior holding power for ferrous materials without the need for physical clamps, enabling faster setup and improved precision in machining operations. Their ability to hold irregularly shaped or thin workpieces securely reduces the risk of damage and enhances safety during high-speed cutting. You benefit from lower maintenance requirements and increased versatility compared to mechanical chucks, which rely on mechanical force and are often limited by size and shape constraints.

Advantages of Mechanical Chucks

Mechanical chucks offer superior gripping force and reliability for heavy-duty machining tasks, ensuring consistent workpiece stability. They are less affected by material properties, making them versatile for clamping non-ferrous and irregularly shaped objects. Maintenance is straightforward due to their robust design, reducing downtime in industrial operations.

Limitations of Magnetic Chucks

Magnetic chucks are limited by their inability to securely hold non-ferrous or thin materials, reducing their versatility compared to mechanical chucks. They also require a consistent power source for electromagnetic types, which can cause operational downtime during power failures. Surface contamination such as rust, oil, or dirt can significantly weaken the magnetic grip, affecting machining precision and safety.

Limitations of Mechanical Chucks

Mechanical chucks face limitations such as reduced gripping power on irregular or delicate workpieces due to their reliance on physical clamping force. They often require manual adjustment and can cause deformation or damage to softer materials, limiting their versatility. Furthermore, mechanical chucks typically have slower setup times compared to magnetic chucks, impacting production efficiency in high-volume machining environments.

Applications: When to Use Magnetic or Mechanical Chucks

Magnetic chucks are ideal for holding ferromagnetic workpieces in applications such as grinding, surface finishing, and light machining where quick, secure clamping without deformation is essential. Mechanical chucks provide superior grip strength and versatility for non-magnetic materials or heavier, irregularly shaped parts in turning, milling, and drilling operations requiring high torque and stability. Choosing between magnetic and mechanical chucks depends on workpiece material, machining process, and the need for rapid setup or maximum holding force.

Choosing the Right Chuck for Your Machining Needs

Selecting the right chuck for machining hinges on the workpiece material and desired precision; magnetic chucks excel with ferromagnetic materials, offering quick setup and uniform gripping without mechanical distortion. Mechanical chucks provide versatile gripping for a variety of materials, including non-magnetic metals and irregular shapes, ensuring secure clamping with adjustable jaws. Prioritizing factors such as material compatibility, clamping force, and ease of use enables optimal selection between magnetic and mechanical chucks for efficient machining performance.

Magnetic chuck vs mechanical chuck Infographic

libmatt.com

libmatt.com