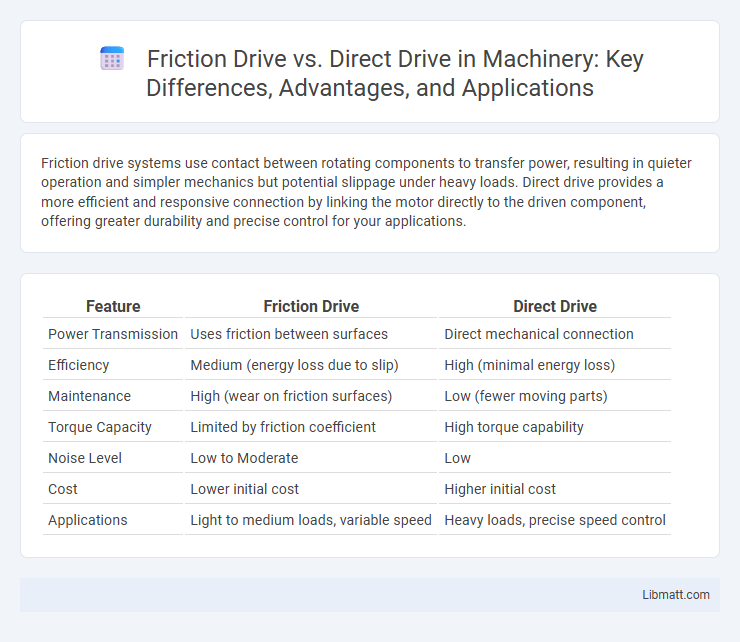

Friction drive systems use contact between rotating components to transfer power, resulting in quieter operation and simpler mechanics but potential slippage under heavy loads. Direct drive provides a more efficient and responsive connection by linking the motor directly to the driven component, offering greater durability and precise control for your applications.

Table of Comparison

| Feature | Friction Drive | Direct Drive |

|---|---|---|

| Power Transmission | Uses friction between surfaces | Direct mechanical connection |

| Efficiency | Medium (energy loss due to slip) | High (minimal energy loss) |

| Maintenance | High (wear on friction surfaces) | Low (fewer moving parts) |

| Torque Capacity | Limited by friction coefficient | High torque capability |

| Noise Level | Low to Moderate | Low |

| Cost | Lower initial cost | Higher initial cost |

| Applications | Light to medium loads, variable speed | Heavy loads, precise speed control |

Introduction to Friction Drive and Direct Drive

Friction drive systems transmit power through the contact of two rotating surfaces, relying on friction to transfer motion without gears or belts, commonly found in turntables and smaller machinery. Direct drive connects the motor directly to the load, eliminating intermediary components for higher efficiency, precision, and reduced maintenance, often used in modern electric vehicles and industrial equipment. You can optimize performance by choosing friction drive for simple, low-cost applications and direct drive for high-torque, precise control scenarios.

How Friction Drive Systems Work

Friction drive systems operate by transferring motion through the contact friction between a driving wheel and a driven surface, allowing smooth speed variation and torque control. Unlike direct drive, which connects the motor directly to the load, friction drives use rubber or polyurethane wheels to modulate power without gears. Your machinery benefits from reduced mechanical complexity and quieter operation, but consistent contact pressure and surface conditions are crucial for optimal performance.

How Direct Drive Systems Operate

Direct drive systems operate by connecting the motor's rotor directly to the driven load, eliminating intermediate gears or belts for streamlined power transmission. This design enhances efficiency by reducing energy loss typically caused by friction in gear trains, resulting in precise torque delivery and smoother operation. Common applications include high-performance turntables, electric vehicles, and industrial machinery where minimal maintenance and high reliability are critical.

Key Differences Between Friction Drive and Direct Drive

Friction drive systems rely on the contact between rotating components to transmit power, resulting in simpler construction but potential slippage under heavy loads, while direct drive systems connect the motor shaft directly to the driven load, offering higher efficiency and precise control. The key differences include efficiency levels, maintenance requirements, noise generation, and performance consistency; friction drives tend to be quieter and easier to maintain but less efficient, whereas direct drives provide superior torque output and longevity. Understanding these distinctions helps you select the optimal drive system tailored to your application's speed, torque, and durability needs.

Efficiency Comparison: Friction vs Direct Drive

Direct drive systems typically offer higher efficiency by minimizing energy loss through fewer moving parts and eliminating intermediary friction components. Friction drive mechanisms can result in reduced efficiency due to slippage and surface wear, which lead to energy dissipation. Overall, direct drive maintains superior energy transfer efficiency, making it preferable for applications demanding consistent power output.

Advantages of Friction Drive Systems

Friction drive systems offer smoother acceleration and quieter operation compared to direct drive, reducing mechanical noise and vibration in your machinery. Their simple construction allows for easier maintenance and lower production costs, making them ideal for compact or low-speed applications. The ability to easily adjust speed by changing the contact point between friction components provides flexible control not typically available in fixed-ratio direct drive systems.

Benefits of Direct Drive Technology

Direct drive technology offers superior efficiency by eliminating intermediary components, resulting in reduced energy loss and enhanced power transfer. This design minimizes maintenance requirements and improves reliability, providing longer lifespan and consistent performance. Your machinery benefits from quieter operation and smoother motion control, making direct drive an optimal choice for precision applications.

Common Applications for Friction and Direct Drives

Friction drives are commonly used in low-torque applications such as turntables, conveyor belts, and simple mechanical clocks where quiet operation and smooth variable speed control are essential. Direct drives are favored in high-torque, precision applications like electric vehicles, industrial robots, and hard disk drives due to their efficiency, reliability, and minimal maintenance requirements. Both drive types cater to specific operational needs, with friction drives excelling in smaller scale and variable speed scenarios while direct drives dominate in high-performance, heavy-duty environments.

Maintenance and Longevity: Which System Lasts Longer?

Friction drive systems require more frequent maintenance due to wear on contact surfaces, leading to shorter lifespan compared to direct drive systems. Direct drive mechanisms benefit from fewer moving parts and reduced friction, resulting in increased durability and longer operational life. Regular lubrication and precise alignment further extend the longevity of direct drive systems, making them more reliable for long-term use.

Choosing the Right Drive System for Your Needs

Friction drive systems excel in applications requiring smooth, quiet operation and easy speed variation, making them ideal for light-duty or variable-speed machinery. Direct drive systems offer superior efficiency, durability, and precise control, suited for high-torque, high-performance equipment such as industrial motors and electric vehicles. Evaluating factors like load capacity, maintenance requirements, and operational environment ensures selection of the optimal drive system for specific mechanical needs.

Friction drive vs direct drive Infographic

libmatt.com

libmatt.com