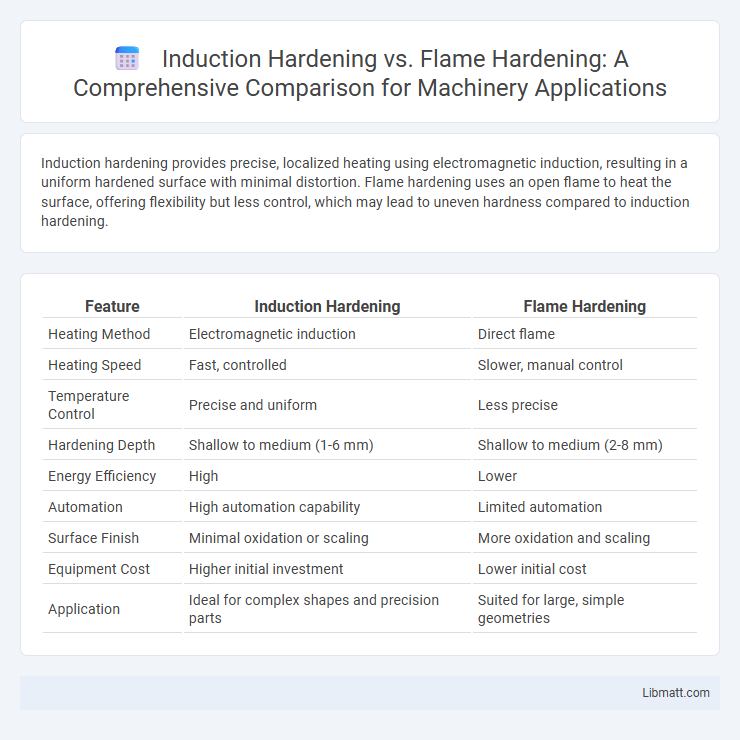

Induction hardening provides precise, localized heating using electromagnetic induction, resulting in a uniform hardened surface with minimal distortion. Flame hardening uses an open flame to heat the surface, offering flexibility but less control, which may lead to uneven hardness compared to induction hardening.

Table of Comparison

| Feature | Induction Hardening | Flame Hardening |

|---|---|---|

| Heating Method | Electromagnetic induction | Direct flame |

| Heating Speed | Fast, controlled | Slower, manual control |

| Temperature Control | Precise and uniform | Less precise |

| Hardening Depth | Shallow to medium (1-6 mm) | Shallow to medium (2-8 mm) |

| Energy Efficiency | High | Lower |

| Automation | High automation capability | Limited automation |

| Surface Finish | Minimal oxidation or scaling | More oxidation and scaling |

| Equipment Cost | Higher initial investment | Lower initial cost |

| Application | Ideal for complex shapes and precision parts | Suited for large, simple geometries |

Introduction to Surface Hardening Techniques

Surface hardening techniques like induction hardening and flame hardening improve the wear resistance and fatigue strength of metal components by altering only the outer layer's microstructure. Induction hardening uses electromagnetic induction to heat the surface rapidly, followed by quenching, producing a precise, hardened case with minimal distortion. Flame hardening employs an oxy-fuel flame to heat the surface before quenching, making it suitable for larger or irregularly shaped parts but with less control over heating depth and uniformity.

Understanding Induction Hardening

Induction hardening uses electromagnetic induction to heat and harden specific metal areas, offering precise control over depth and hardness, which is ideal for complex shapes and high-volume production. This method improves wear resistance and fatigue strength without affecting the entire component, preserving the metal's core properties. Your choice between induction and flame hardening should consider factors like efficiency, accuracy, and the desired mechanical characteristics of the final product.

Overview of Flame Hardening

Flame hardening is a heat treatment process that uses an oxy-fuel flame to rapidly heat the surface of steel components followed by immediate quenching, resulting in a hardened outer layer while maintaining a tough core. This method is primarily employed for large parts and components with simple geometries, providing localized hardness improvements and increased wear resistance. It offers flexibility in treating selected areas but may lead to surface decarburization and requires skilled control to ensure uniform hardness depth.

Key Differences Between Induction and Flame Hardening

Induction hardening utilizes electromagnetic induction to rapidly heat and quench specific areas of a metal part, resulting in precise and uniform surface hardening, while flame hardening employs an oxy-fuel gas flame to heat the surface before quenching, which can cause less controlled heating and more distortion. Induction hardening provides faster processing times, higher repeatability, and better energy efficiency compared to flame hardening, which is typically more suitable for larger, irregularly shaped components. Key differences also include the precision of heating zones, with induction hardening offering localized and consistent hardening depth, whereas flame hardening often delivers variable hardening depths depending on operator skill and flame control.

Applications of Induction Hardening

Induction hardening is widely used in automotive and aerospace industries for enhancing the wear resistance of gears, shafts, and camshafts due to its precise heating and controlled hardening depth. This method offers superior repeatability and energy efficiency compared to flame hardening, making it ideal for high-volume production of critical components requiring consistent mechanical properties. Your manufacturing process can benefit from induction hardening when targeting improved fatigue strength and hardness in complex-shaped parts.

Applications of Flame Hardening

Flame hardening is widely used for improving wear resistance and fatigue strength in automotive components, such as gears, shafts, and camshafts, that require localized surface hardening without affecting the entire part. This technique effectively enhances the durability of tools, agricultural machinery parts, and steel structural components exposed to high stress and abrasive conditions. You can achieve rapid heating and controlled hardening depths with flame hardening, making it suitable for medium and large-sized parts needing selective surface treatment.

Advantages of Induction Hardening

Induction hardening offers precise control over heating depth and temperature, resulting in uniform hardness and minimal distortion of the workpiece. This method is highly efficient, providing rapid heating with energy savings compared to flame hardening. Your components benefit from improved fatigue resistance and consistent mechanical properties due to the controlled and repeatable process of induction hardening.

Advantages of Flame Hardening

Flame hardening offers precise control over the hardened area, enabling selective surface treatment without affecting the core material properties. This method is cost-effective for medium-sized batch production and provides quick heating cycles, reducing overall processing time. Its flexibility allows treatment of complex shapes and large components, making it suitable for parts that require enhanced wear resistance and fatigue strength.

Limitations and Challenges of Each Method

Induction hardening faces limitations such as uneven heating on complex geometries and requires precise equipment calibration to avoid overheating or distortion, leading to challenges in treating large or irregularly shaped components. Flame hardening encounters difficulties with controlling temperature uniformity and depth of hardening, which can cause inconsistent surface properties and increased risk of thermal stresses or warping. Both methods demand careful process control and skilled operation to balance hardness, durability, and dimensional accuracy in varying applications.

Choosing the Right Hardening Process for Your Needs

Induction hardening offers precise control over heating depth and is ideal for complex or small components requiring uniform hardness and minimal distortion. Flame hardening provides flexibility for larger surfaces and can be more cost-effective for simpler shapes but may result in less consistent hardness. Selecting the appropriate process depends on factors like part geometry, desired hardness depth, production volume, and cost considerations.

Induction hardening vs flame hardening Infographic

libmatt.com

libmatt.com