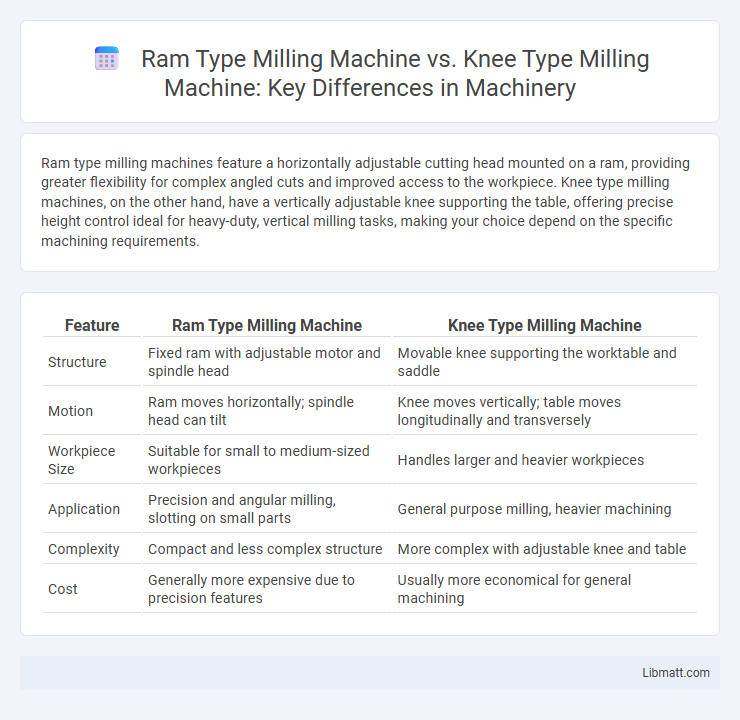

Ram type milling machines feature a horizontally adjustable cutting head mounted on a ram, providing greater flexibility for complex angled cuts and improved access to the workpiece. Knee type milling machines, on the other hand, have a vertically adjustable knee supporting the table, offering precise height control ideal for heavy-duty, vertical milling tasks, making your choice depend on the specific machining requirements.

Table of Comparison

| Feature | Ram Type Milling Machine | Knee Type Milling Machine |

|---|---|---|

| Structure | Fixed ram with adjustable motor and spindle head | Movable knee supporting the worktable and saddle |

| Motion | Ram moves horizontally; spindle head can tilt | Knee moves vertically; table moves longitudinally and transversely |

| Workpiece Size | Suitable for small to medium-sized workpieces | Handles larger and heavier workpieces |

| Application | Precision and angular milling, slotting on small parts | General purpose milling, heavier machining |

| Complexity | Compact and less complex structure | More complex with adjustable knee and table |

| Cost | Generally more expensive due to precision features | Usually more economical for general machining |

Introduction to Milling Machines

Ram type milling machines feature a movable ram allowing the spindle to adjust forward or backward, enhancing versatility for various cutting operations. Knee type milling machines have a vertically adjustable knee that supports the worktable, providing precise height adjustments for different workpiece sizes. These structural differences define their applications, with ram type machines suited for heavy-duty, flexible machining and knee type machines preferred for precision tasks.

Overview of Ram Type Milling Machines

Ram type milling machines feature an adjustable ram that allows the cutting head to move forward, backward, and side-to-side, offering greater flexibility in machining complex surfaces. The ram design supports heavy-duty cutting operations and provides enhanced precision when working with irregular or intricate shapes. These machines excel in manufacturing processes requiring versatile tool positioning and are widely used in die sinking and mold making industries.

Overview of Knee Type Milling Machines

Knee type milling machines feature a vertically adjustable saddle and table supported by a sturdy knee, allowing precise vertical movement for various machining operations. This design enables flexibility in handling heavy workpieces with enhanced stability and accuracy, making it ideal for complex milling tasks. The knee's vertical adjustment capability distinguishes it from ram type machines, which rely on a sliding ram for cutter positioning.

Structural Differences Between Ram and Knee Type

Ram type milling machines feature a horizontally sliding ram mounted on a vertical column, allowing the cutting tool to move forward and backward for enhanced versatility. Knee type milling machines have a vertically adjustable knee that supports the saddle and table, enabling precise vertical positioning of the workpiece. The ram structure provides dynamic tool movement, while the knee structure offers stable vertical adjustments, catering to distinct machining operations.

Table Movement and Working Capabilities

Ram type milling machines feature a fixed table with the ram and cutting head able to move, allowing versatile positioning of the tool for complex machining tasks. Knee type milling machines have a movable table that travels vertically and horizontally along the knee, providing stable workpiece support for heavy-duty milling operations. The ram design excels in flexible tool adjustments, while the knee type offers robust table movement suited for precise, heavy material removal.

Spindle and Head Adjustability

Ram type milling machines feature a spindle mounted on a sliding ram that allows forward and backward movement, providing enhanced head adjustability for complex machining angles. Knee type milling machines have a fixed spindle with vertical movement achieved by raising or lowering the knee, offering limited head adjustability compared to the ram type. Your choice depends on the need for versatile spindle positioning, where ram type machines excel in flexibility and knee type machines prioritize stability.

Applications and Industry Uses

Ram type milling machines are widely used in industries requiring heavy-duty precision machining, such as aerospace, automotive, and die-making, due to their ability to perform complex shaping and drilling on large workpieces. Knee type milling machines are preferred in workshops and educational settings for general-purpose milling tasks, including slotting, drilling, and contouring of medium-sized components in manufacturing and maintenance. The ram type's adjustable ram head allows versatility in machining irregular surfaces, while the knee type's vertically adjustable table suits straightforward milling operations.

Advantages of Ram Type Milling Machines

Ram type milling machines offer superior flexibility with an adjustable ram that can be swiveled and extended, allowing precise machining of complex surfaces and angles. Their design enables quick tool changes and enhanced access to the workpiece, increasing productivity in varied milling operations. These machines provide better control over cutting forces, resulting in improved accuracy and surface finish compared to knee type milling machines.

Advantages of Knee Type Milling Machines

Knee type milling machines offer superior flexibility due to their adjustable worktable, allowing precise vertical and horizontal movement for complex machining tasks. They provide better stability and support for heavy workpieces, enhancing machining accuracy and durability during prolonged operations. Your ability to easily position and lock the worktable makes knee type mills ideal for detailed, dimensionally accurate milling projects.

Choosing the Right Milling Machine for Your Needs

Ram type milling machines offer adjustable heads that provide flexible positioning, making them ideal for complex or angled machining tasks, while knee type milling machines feature a vertically adjustable worktable suitable for precise vertical movements and general-purpose milling. Your choice depends on the specific machining operations, with ram type machines favored for versatility and knee type machines preferred for straightforward vertical cuts. Considering the workpiece size, precision required, and complexity of cuts will guide you to select the milling machine that best fits your manufacturing requirements.

Ram type milling machine vs knee type milling machine Infographic

libmatt.com

libmatt.com