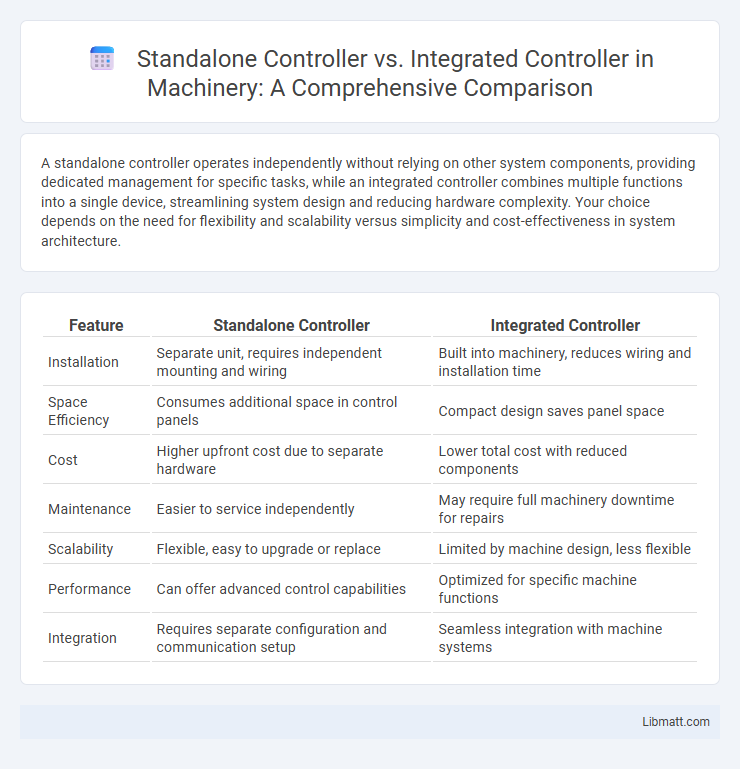

A standalone controller operates independently without relying on other system components, providing dedicated management for specific tasks, while an integrated controller combines multiple functions into a single device, streamlining system design and reducing hardware complexity. Your choice depends on the need for flexibility and scalability versus simplicity and cost-effectiveness in system architecture.

Table of Comparison

| Feature | Standalone Controller | Integrated Controller |

|---|---|---|

| Installation | Separate unit, requires independent mounting and wiring | Built into machinery, reduces wiring and installation time |

| Space Efficiency | Consumes additional space in control panels | Compact design saves panel space |

| Cost | Higher upfront cost due to separate hardware | Lower total cost with reduced components |

| Maintenance | Easier to service independently | May require full machinery downtime for repairs |

| Scalability | Flexible, easy to upgrade or replace | Limited by machine design, less flexible |

| Performance | Can offer advanced control capabilities | Optimized for specific machine functions |

| Integration | Requires separate configuration and communication setup | Seamless integration with machine systems |

Overview of Standalone and Integrated Controllers

Standalone controllers operate independently, managing specific functions without relying on other systems, which ensures dedicated performance and simplified troubleshooting. Integrated controllers combine multiple control functions into a single unit, optimizing system coordination, reducing hardware redundancy, and enabling streamlined communication between components. Your choice between standalone and integrated controllers depends on application complexity, scalability needs, and budget considerations.

Key Differences Between Standalone and Integrated Controllers

Standalone controllers operate independently, offering dedicated processing power and enhanced customization options for specific tasks. Integrated controllers combine controller functions within other system components, providing streamlined design, space-saving, and cost efficiency. Key differences include the level of hardware independence, scalability potential, and ease of maintenance.

Core Functions of Standalone Controllers

Standalone controllers manage specific HVAC or automation tasks independently, ensuring precise control over temperature, humidity, or lighting without relying on an external system. These controllers feature core functions such as direct sensor input processing, programmed logic execution, and real-time adjustments to maintain optimal environmental conditions. Your system benefits from increased reliability and simplified troubleshooting due to the dedicated processing capabilities of standalone controllers.

Core Functions of Integrated Controllers

Integrated controllers combine multiple core functions such as processing, data storage, and communication interfaces within a single unit, enhancing system efficiency and reducing hardware complexity. These controllers streamline operations by managing inputs and outputs while facilitating real-time processing and diagnostics, which improves overall performance and reliability. Your system benefits from faster response times and simplified maintenance compared to standalone controllers that handle each function separately.

Pros and Cons of Standalone Controllers

Standalone controllers offer precise, dedicated control for specific systems, enhancing reliability and performance in complex automation environments. They simplify troubleshooting and maintenance by isolating control functions but often require additional wiring and physical space, increasing installation costs. Limited integration capabilities with other systems may reduce overall scalability and data visibility compared to integrated controllers.

Pros and Cons of Integrated Controllers

Integrated controllers offer a space-saving design by combining multiple control functions into a single unit, reducing wiring complexity and installation costs. They enhance system reliability through streamlined communication between components but may limit flexibility since upgrading one function often requires replacing the entire unit. Maintenance can become more challenging due to the interdependency of integrated parts, increasing downtime risks compared to standalone controllers.

Performance Comparison: Standalone vs Integrated

Standalone controllers typically offer superior performance with dedicated processing power and optimized hardware for specific tasks, ensuring faster response times and higher precision. Integrated controllers combine functions within a single system, which may reduce latency due to fewer communication layers but can suffer from resource sharing that limits peak performance. Understanding your application requirements helps determine whether a standalone controller's specialized capabilities or an integrated controller's streamlined design better suits your performance needs.

Application Scenarios for Each Controller Type

Standalone controllers excel in applications requiring dedicated control over specific processes, such as HVAC systems, industrial automation, or machinery where isolated and reliable operation is critical. Integrated controllers are ideal for environments demanding centralized management, like smart homes or complex manufacturing systems, offering seamless communication and coordination among multiple devices. Your choice depends on whether your setup prioritizes focused, independent control or interconnected, system-wide integration.

Cost Considerations and Scalability

Standalone controllers typically involve higher initial costs due to dedicated hardware and installation expenses but offer easier scalability by adding more units as needed. Integrated controllers, embedded within existing systems, reduce upfront expenditures and simplify maintenance, yet scalability may be limited by the host system's capacity and compatibility. Your choice should balance budget constraints with future growth requirements, optimizing cost-efficiency while ensuring flexible system expansion.

Choosing the Right Controller for Your System

Choosing the right controller for your system depends on factors such as complexity, cost, and scalability. Standalone controllers offer dedicated processing power and flexibility, ideal for systems requiring high customization and robust performance. Integrated controllers combine multiple functions into one unit, reducing hardware and simplifying installation, making them suitable for compact or budget-conscious applications where space and cost efficiency are priorities.

Standalone controller vs integrated controller Infographic

libmatt.com

libmatt.com