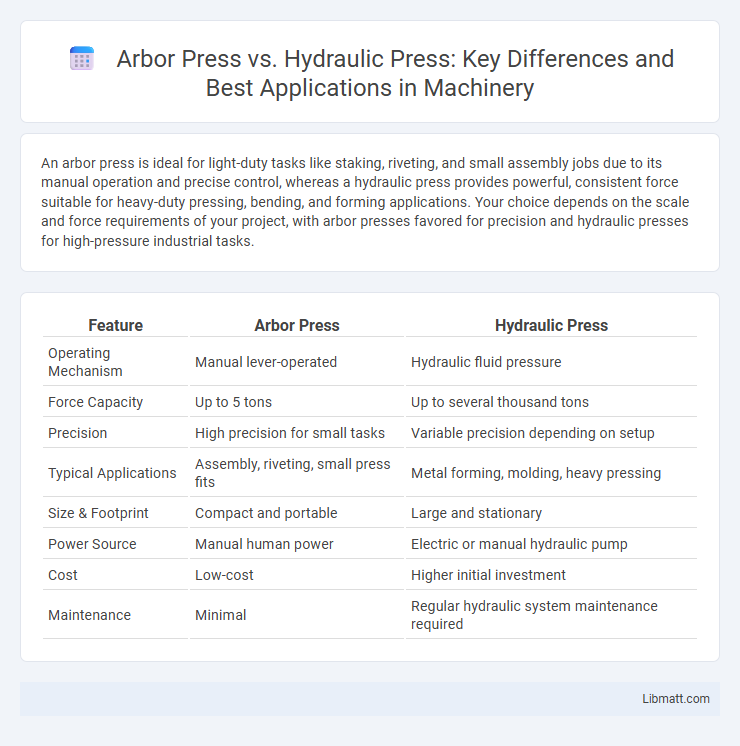

An arbor press is ideal for light-duty tasks like staking, riveting, and small assembly jobs due to its manual operation and precise control, whereas a hydraulic press provides powerful, consistent force suitable for heavy-duty pressing, bending, and forming applications. Your choice depends on the scale and force requirements of your project, with arbor presses favored for precision and hydraulic presses for high-pressure industrial tasks.

Table of Comparison

| Feature | Arbor Press | Hydraulic Press |

|---|---|---|

| Operating Mechanism | Manual lever-operated | Hydraulic fluid pressure |

| Force Capacity | Up to 5 tons | Up to several thousand tons |

| Precision | High precision for small tasks | Variable precision depending on setup |

| Typical Applications | Assembly, riveting, small press fits | Metal forming, molding, heavy pressing |

| Size & Footprint | Compact and portable | Large and stationary |

| Power Source | Manual human power | Electric or manual hydraulic pump |

| Cost | Low-cost | Higher initial investment |

| Maintenance | Minimal | Regular hydraulic system maintenance required |

Introduction to Arbor Press and Hydraulic Press

An Arbor press is a manually operated tool designed for small-scale tasks such as pressing bearings, staking, and riveting, offering precision and control with minimal force. A hydraulic press uses fluid pressure to generate significant force for heavy-duty applications, including metal forming, molding, and large-scale stamping. Your choice depends on the scale and intensity of the task, with arbor presses suited for lighter, detailed work and hydraulic presses for industrial strength requirements.

Working Principles of Arbor and Hydraulic Presses

Arbor presses operate using a lever and gearing mechanism to exert manual force, ideal for small-scale pressing, riveting, and bending tasks. Hydraulic presses utilize Pascal's principle, employing hydraulic fluid under pressure to generate a powerful, evenly distributed force for heavy-duty pressing and shaping applications. The mechanical advantage of hydraulic systems enables higher force output compared to the manual operation of arbor presses.

Key Differences Between Arbor and Hydraulic Presses

Arbor presses are manually operated machines primarily used for small-scale pressing tasks with limited force, typically ranging from 1 to 10 tons, making them ideal for precision assembly and light fabrication. Hydraulic presses utilize fluid power to generate significantly higher forces, often exceeding 100 tons, allowing for heavy-duty applications such as metal forming, punching, and large-scale molding. The key differences lie in their force capacity, operation method--manual versus hydraulic--and suitability for either delicate tasks or robust industrial processes.

Applications: When to Use Arbor or Hydraulic Press

Arbor presses are ideal for precision tasks such as assembling small parts, staking, and light-duty pressing where controlled force and accuracy are crucial. Hydraulic presses excel in heavy-duty applications like metal forming, deep drawing, and large-scale assembly, providing high force and consistent pressure for industrial manufacturing. Choose an arbor press for delicate or low-force operations, and a hydraulic press for demanding tasks requiring powerful and adjustable pressing capabilities.

Force and Capacity Comparison

Arbor presses typically deliver force ranging from 1 to 10 tons, suitable for light to medium-duty tasks such as pressing bearings or small assemblies. Hydraulic presses offer significantly higher capacity, often exceeding 100 tons, enabling them to handle heavy-duty applications like metal forming and large-scale stamping. Your choice between the two depends on the required force and the scale of your manufacturing needs.

Precision and Control in Press Operations

Arbor presses offer superior precision and control for small-scale press operations due to their manual operation and simple mechanical design, making them ideal for delicate tasks requiring consistent force application. Hydraulic presses provide more adjustable pressure with greater force capacity but can be less precise for fine control, as their operation depends on fluid dynamics which may introduce slight variations. Choosing between the two depends on the need for exact force application and the scale of the pressing job, with arbor presses excelling in precision and hydraulic presses in power.

Maintenance Requirements for Each Press Type

Arbor presses require minimal maintenance, primarily involving regular lubrication of moving parts and periodic inspection for wear on mechanical components. Hydraulic presses demand more rigorous upkeep, including frequent checks and replacement of hydraulic fluid, inspection of seals for leaks, and ensuring proper pressure levels to maintain efficiency. Both types benefit from routine cleaning, but hydraulic presses necessitate specialized knowledge to manage their complex hydraulic systems effectively.

Cost Considerations: Initial and Operational Expenses

Arbor presses typically have lower initial costs, making them ideal for small workshops with limited budgets, whereas hydraulic presses require a higher upfront investment due to their complex components and power systems. Operational expenses for arbor presses remain minimal as they rely on manual operation, but hydraulic presses incur ongoing costs related to maintenance, hydraulic fluid replacement, and energy consumption. Businesses seeking cost-efficiency for light-duty tasks often prefer arbor presses, while those handling heavy-duty, high-volume production may justify hydraulic press expenses through enhanced productivity.

Safety Features and User Considerations

Arbor presses offer greater control and simpler safety features, making them ideal for light to moderate tasks where precise manual operation is critical. Hydraulic presses incorporate advanced safety mechanisms like pressure relief valves and emergency stop buttons to handle heavy-duty applications, reducing the risk of accidents under high force conditions. When choosing Your press, consider the complexity of the job and the safety requirements to ensure optimal protection and ease of use.

Choosing the Right Press for Your Workshop

Arbor presses offer precise control and are ideal for light to medium-duty tasks such as staking, riveting, and small assembly jobs, making them suitable for workshops focused on detailed manual work. Hydraulic presses provide greater force and efficiency for heavy-duty applications like metal forming, punching, and large-scale manufacturing processes, making them essential for workshops requiring high power and automation. Evaluating your workshop's workload, material types, and desired accuracy will help you choose the right press and optimize productivity.

Arbor press vs hydraulic press Infographic

libmatt.com

libmatt.com