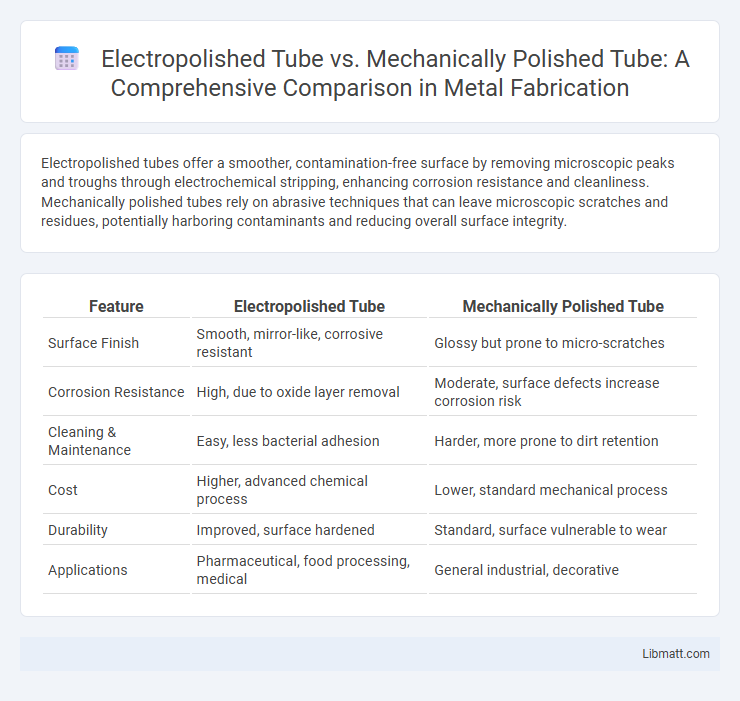

Electropolished tubes offer a smoother, contamination-free surface by removing microscopic peaks and troughs through electrochemical stripping, enhancing corrosion resistance and cleanliness. Mechanically polished tubes rely on abrasive techniques that can leave microscopic scratches and residues, potentially harboring contaminants and reducing overall surface integrity.

Table of Comparison

| Feature | Electropolished Tube | Mechanically Polished Tube |

|---|---|---|

| Surface Finish | Smooth, mirror-like, corrosive resistant | Glossy but prone to micro-scratches |

| Corrosion Resistance | High, due to oxide layer removal | Moderate, surface defects increase corrosion risk |

| Cleaning & Maintenance | Easy, less bacterial adhesion | Harder, more prone to dirt retention |

| Cost | Higher, advanced chemical process | Lower, standard mechanical process |

| Durability | Improved, surface hardened | Standard, surface vulnerable to wear |

| Applications | Pharmaceutical, food processing, medical | General industrial, decorative |

Introduction to Electropolished and Mechanically Polished Tubes

Electropolished tubes undergo an electrochemical process that removes a thin surface layer, resulting in a smoother, cleaner finish with enhanced corrosion resistance and reduced surface roughness below 0.1 microns. Mechanically polished tubes use abrasive methods such as grinding or buffing to achieve a polished surface, which may leave microscopic scratches and a roughness typically above 0.2 microns. Electropolishing improves hygiene and durability, making it ideal for pharmaceutical and food industries, whereas mechanical polishing is often preferred for aesthetic purposes in decorative applications.

Understanding Tube Surface Finishing Methods

Electropolished tubes achieve a smoother, more uniform surface by removing a thin layer of metal through an electrochemical process, enhancing corrosion resistance and cleanliness compared to mechanically polished tubes, which rely on abrasive methods to physically smooth surfaces but may leave microscopic grooves. This distinction significantly impacts tube performance in industries like pharmaceuticals and food processing where sanitary conditions and reduced contamination risks are critical. Understanding these surface finishing methods helps you select the optimal tube type for your application's hygiene and durability requirements.

Key Differences Between Electropolishing and Mechanical Polishing

Electropolished tubes undergo an electrochemical process that removes a thin layer of metal, resulting in a smooth, oxide-free, and corrosion-resistant surface, while mechanically polished tubes rely on abrasive techniques to physically smooth the surface. The electropolishing process enhances surface cleanliness and passivation, improving hygiene and resistance to bacterial growth, compared to mechanical polishing which may leave microscopic scratches harboring contaminants. Electropolished tubes also exhibit improved durability and chemical resistance, making them ideal for pharmaceutical, food processing, and semiconductor applications where surface integrity is critical.

Surface Finish Quality: A Comparative Analysis

Electropolished tubes exhibit superior surface finish quality by achieving a smoother, microscopically uniform surface compared to mechanically polished tubes, which often retain microscratches and imperfections due to abrasive methods. The electropolishing process removes a precise layer of material, eliminating surface contaminants and creating a passivated, corrosion-resistant layer, enhancing cleanliness and durability crucial for medical, pharmaceutical, and semiconductor applications. In contrast, mechanical polishing relies on physical abrasion, resulting in variable finishes dependent on operator skill, frequently requiring additional cleaning steps to achieve similar levels of surface purity.

Corrosion Resistance: Electropolished vs Mechanically Polished Tubes

Electropolished tubes exhibit superior corrosion resistance due to the removal of microscopic surface imperfections and embedded contaminants, creating a smooth, passive oxide layer that protects against oxidation and corrosion. Mechanically polished tubes may retain micro-scratches and embedded particles, which act as initiation sites for corrosion and reduce overall durability in harsh environments. The electropolishing process enhances chemical resistance and extends tube lifespan in industries such as pharmaceuticals, food processing, and semiconductor manufacturing.

Cleanliness and Contamination Control

Electropolished tubes offer superior cleanliness due to their smoother surface finish, which reduces crevices and inhibits microbial adhesion compared to mechanically polished tubes that may retain microscopic contaminants within surface irregularities. The electropolishing process removes a thin layer of material, eliminating embedded particles and potential contamination sites, enhancing contamination control in critical applications like pharmaceuticals and food processing. Mechanically polished tubes, with their less uniform finish, can harbor residues and biofilms, making them less optimal for environments requiring stringent hygiene standards.

Applications in Various Industries

Electropolished tubes provide superior surface smoothness and corrosion resistance, making them ideal for pharmaceutical, food processing, and semiconductor industries where hygiene and purity are critical. Mechanically polished tubes, while smoother than as-fabricated finishes, are more commonly used in architectural, automotive, and general industrial applications where aesthetic appearance and moderate corrosion resistance suffice. Your choice between electropolished and mechanically polished tubes impacts performance, maintenance, and compliance with industry-specific standards.

Cost Implications and Efficiency

Electropolished tubes typically incur higher upfront costs due to specialized equipment and processing time, but they enhance surface cleanliness and corrosion resistance, leading to improved operational efficiency and longer service life. Mechanically polished tubes are usually less expensive initially but may require more frequent maintenance and replacement due to surface imperfections that can harbor contaminants. Choosing electropolishing for Your tubes can reduce long-term expenses by minimizing downtime and enhancing overall system performance.

Choosing the Right Tube Finish for Your Project

Electropolished tubes offer a smoother, more corrosion-resistant surface compared to mechanically polished tubes, making them ideal for applications requiring enhanced cleanliness and reduced bacterial adhesion, such as in pharmaceutical and food industries. Mechanically polished tubes provide a visually appealing finish with customizable texture but may retain microscopic imperfections that affect long-term durability. Selecting the right tube finish depends on your project's requirements for hygiene, corrosion resistance, and surface quality.

Conclusion: Which Polishing Method is Superior?

Electropolished tubes offer a superior surface finish with enhanced corrosion resistance and reduced bacterial contamination compared to mechanically polished tubes. Their smooth, passivated surface improves cleanability and durability, making them ideal for industries like pharmaceuticals and food processing. Mechanical polishing, while effective for removing imperfections, cannot match the uniformity and long-term protective benefits of electropolishing.

Electropolished Tube vs Mechanically Polished Tube Infographic

libmatt.com

libmatt.com