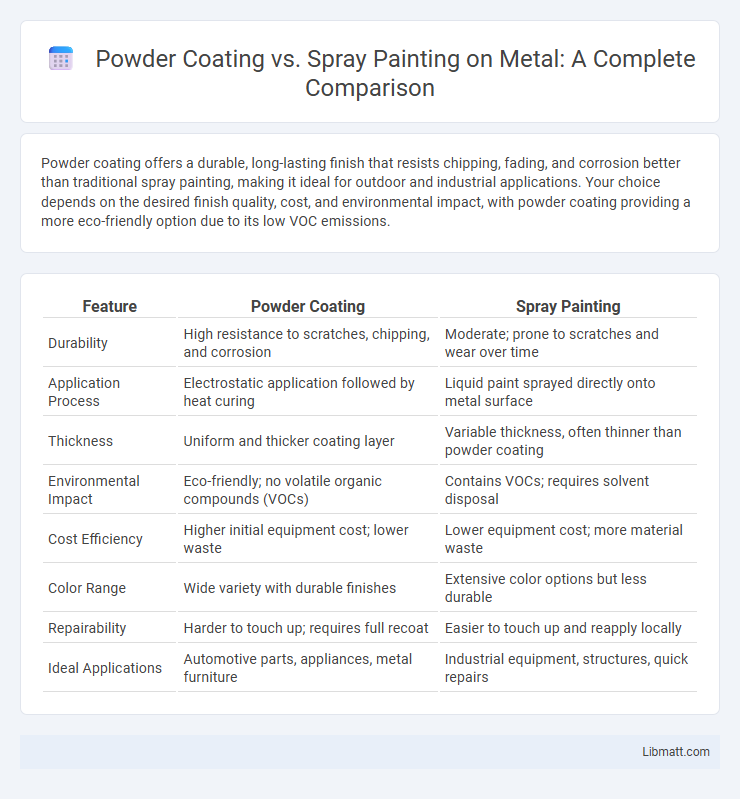

Powder coating offers a durable, long-lasting finish that resists chipping, fading, and corrosion better than traditional spray painting, making it ideal for outdoor and industrial applications. Your choice depends on the desired finish quality, cost, and environmental impact, with powder coating providing a more eco-friendly option due to its low VOC emissions.

Table of Comparison

| Feature | Powder Coating | Spray Painting |

|---|---|---|

| Durability | High resistance to scratches, chipping, and corrosion | Moderate; prone to scratches and wear over time |

| Application Process | Electrostatic application followed by heat curing | Liquid paint sprayed directly onto metal surface |

| Thickness | Uniform and thicker coating layer | Variable thickness, often thinner than powder coating |

| Environmental Impact | Eco-friendly; no volatile organic compounds (VOCs) | Contains VOCs; requires solvent disposal |

| Cost Efficiency | Higher initial equipment cost; lower waste | Lower equipment cost; more material waste |

| Color Range | Wide variety with durable finishes | Extensive color options but less durable |

| Repairability | Harder to touch up; requires full recoat | Easier to touch up and reapply locally |

| Ideal Applications | Automotive parts, appliances, metal furniture | Industrial equipment, structures, quick repairs |

Introduction to Powder Coating and Spray Painting

Powder coating is a dry finishing process that uses finely ground particles of pigment and resin applied electrostatically to a metal surface, followed by curing under heat to form a hard, durable finish. Spray painting involves applying liquid paint through an air-powered spray gun, creating a thin, even coat that dries through solvent evaporation. Both methods are widely used in industrial and automotive applications, offering distinct advantages in durability, finish quality, and environmental impact.

How Powder Coating Works

Powder coating involves applying a dry powder electrostatically to a metal surface, which is then cured under heat to form a strong, durable finish. Unlike traditional spray painting that uses liquid paint, powder coating creates a thicker, more uniform layer that resists chipping, scratching, and fading. Your metal items receive enhanced protection and a longer-lasting, high-quality appearance through this efficient, environmentally friendly process.

How Spray Painting Works

Spray painting works by atomizing liquid paint into tiny droplets using a spray gun, which are then evenly applied to a surface to create a smooth, uniform finish. The process involves pressurized air or electric systems that propel the paint, allowing it to adhere quickly and dry faster compared to traditional brush methods. Spray painting is ideal for detailed work and surfaces with complex shapes, providing a faster application and versatile color options.

Durability Comparison

Powder coating offers superior durability compared to spray painting, as it forms a thicker, more uniform protective layer that resists chipping, fading, and corrosion over time. The electrostatically applied powder is cured under heat, creating a hard finish that withstands harsh environmental conditions better than traditional liquid paint. Spray paint tends to wear off faster due to thinner layers and less robust adhesion, making powder coating the preferred choice for long-lasting industrial and automotive applications.

Finish Quality and Appearance

Powder coating delivers a thicker, more uniform finish with a smooth, durable surface resistant to chipping, fading, and corrosion, enhancing the overall appearance of metal products. Spray painting allows for more color variety and quick touch-ups but often results in thinner coatings that may show brush marks or uneven texture. In industries where long-lasting, high-quality finishes are essential, powder coating consistently outperforms spray painting in both durability and aesthetic appeal.

Environmental Impact

Powder coating significantly reduces volatile organic compound (VOC) emissions compared to spray painting, resulting in lower air pollution and improved workplace safety. The overspray from powder coating can be collected and reused, minimizing waste, whereas spray painting often produces hazardous overspray that contaminates the environment. Additionally, powder coating's energy-efficient curing process contributes to a smaller carbon footprint relative to the solvent-intensive drying methods of spray painting.

Cost Differences

Powder coating generally offers a higher upfront cost due to specialized equipment and curing ovens, but it provides long-term savings with its durable finish that reduces maintenance and touch-ups. Spray painting has lower initial expenses and is suitable for smaller projects or quick applications, yet may require frequent recoating, increasing overall cost over time. Your choice depends on balancing immediate budget constraints with the desired lifespan and quality of the coating.

Application Process and Equipment

Powder coating involves applying dry powdered paint electrostatically onto a grounded surface, followed by curing in an oven, which creates a durable, uniform finish. Spray painting uses liquid paint sprayed through a gun or aerosol can, requiring multiple coats and drying time between applications. Powder coating equipment includes electrostatic spray guns and curing ovens, whereas spray painting requires air compressors, spray guns, and ventilation systems.

Best Uses and Industry Applications

Powder coating is ideal for industrial applications requiring durable, corrosion-resistant finishes such as automotive parts, appliances, and metal furniture. Spray painting suits projects needing quick, versatile applications on various surfaces like construction materials, indoor decor, and touch-up jobs. Both methods cater to specific industry demands based on finish quality, environmental impact, and production speed.

Choosing the Right Method for Your Project

Powder coating offers superior durability and resistance to chipping, corrosion, and fading, making it ideal for metal surfaces exposed to harsh environments. Spray painting provides more color versatility and is suitable for small-scale or intricate projects where detailed application and quick touch-ups are required. Your choice depends on the project's durability needs, surface type, and desired finish quality.

Powder Coating vs Spray Painting Infographic

libmatt.com

libmatt.com