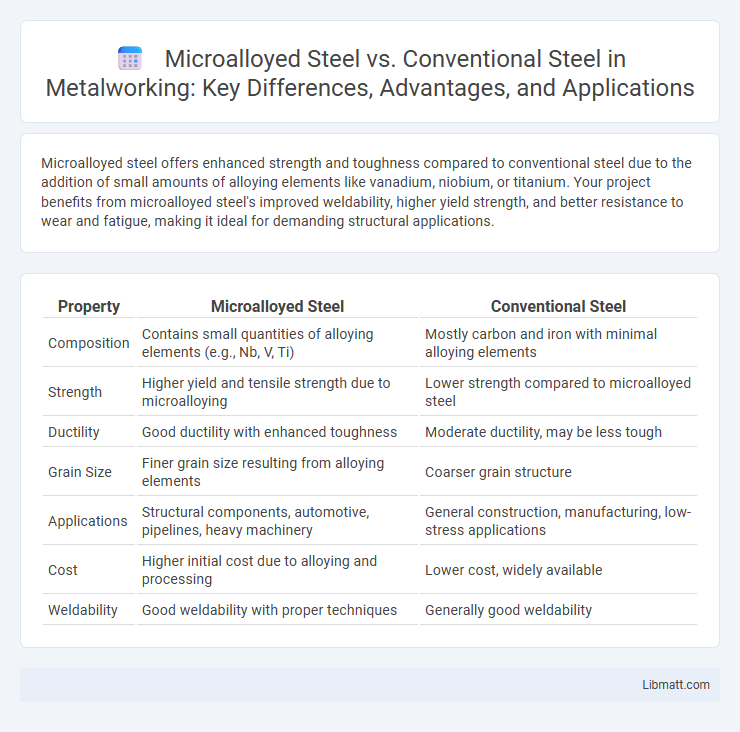

Microalloyed steel offers enhanced strength and toughness compared to conventional steel due to the addition of small amounts of alloying elements like vanadium, niobium, or titanium. Your project benefits from microalloyed steel's improved weldability, higher yield strength, and better resistance to wear and fatigue, making it ideal for demanding structural applications.

Table of Comparison

| Property | Microalloyed Steel | Conventional Steel |

|---|---|---|

| Composition | Contains small quantities of alloying elements (e.g., Nb, V, Ti) | Mostly carbon and iron with minimal alloying elements |

| Strength | Higher yield and tensile strength due to microalloying | Lower strength compared to microalloyed steel |

| Ductility | Good ductility with enhanced toughness | Moderate ductility, may be less tough |

| Grain Size | Finer grain size resulting from alloying elements | Coarser grain structure |

| Applications | Structural components, automotive, pipelines, heavy machinery | General construction, manufacturing, low-stress applications |

| Cost | Higher initial cost due to alloying and processing | Lower cost, widely available |

| Weldability | Good weldability with proper techniques | Generally good weldability |

Introduction to Microalloyed and Conventional Steel

Microalloyed steel contains small amounts of alloying elements such as niobium, vanadium, or titanium, which significantly improve strength, toughness, and weldability compared to conventional steel. Conventional steel primarily consists of iron and carbon with minimal alloy additions, resulting in lower mechanical properties and reduced performance in demanding applications. Choosing microalloyed steel enhances durability and reduces weight in structural components, providing Your projects with superior efficiency and cost-effectiveness.

Chemical Composition Differences

Microalloyed steel contains small additions of alloying elements such as niobium, vanadium, or titanium, typically less than 0.1%, which refine grain size and enhance mechanical properties compared to conventional steel. Conventional steel primarily consists of iron with carbon content usually ranging from 0.1% to 0.3%, lacking these microalloying elements. The presence of these microalloying elements in microalloyed steel promotes precipitation strengthening, resulting in improved strength and toughness without significant alteration of carbon content.

Mechanical Properties Comparison

Microalloyed steel exhibits superior mechanical properties compared to conventional steel, including higher yield strength and improved toughness due to the addition of elements such as niobium, vanadium, and titanium. Fine-grain strengthening in microalloyed steel results in enhanced tensile strength and better fatigue resistance, making it ideal for construction and automotive applications requiring durability. Conventional steel typically shows lower strength and ductility, limiting its performance in demanding environments where microalloyed formulations provide significant advantages.

Microstructural Characteristics

Microalloyed steel exhibits refined grain structures due to the presence of microalloying elements such as niobium, vanadium, and titanium, which promote fine precipitate formation and inhibit grain growth. This enhanced microstructure results in improved strength and toughness compared to conventional steel, which typically has coarser grains and fewer precipitates. Understanding these microstructural characteristics can help you select the appropriate steel type for demanding structural applications requiring increased performance and durability.

Manufacturing Processes

Microalloyed steel incorporates small amounts of alloying elements such as niobium, vanadium, or titanium during the manufacturing process, which refine the grain structure and enhance mechanical properties without the need for extensive heat treatment. Conventional steel typically undergoes simpler hot rolling and thermal processing, relying on carbon content and basic alloying for strength. Your choice of microalloyed steel can reduce manufacturing time and energy consumption while delivering superior strength and toughness.

Cost Implications

Microalloyed steel generally incurs higher initial costs due to the addition of microalloying elements like niobium, vanadium, or titanium, which enhance strength and reduce weight. Despite the upfront expense, these steels often enable cost savings through reduced material usage, lighter structures, and lower transportation costs. Conventional steel has lower raw material costs but may require thicker sections or additional reinforcement, leading to increased fabrication and installation expenses over the project lifecycle.

Applications in Industry

Microalloyed steel offers superior strength and toughness, making it ideal for demanding applications in the automotive, construction, and heavy machinery industries. Its enhanced mechanical properties allow for lighter, more durable components, improving fuel efficiency and structural integrity compared to conventional steel. Your choice of microalloyed steel can lead to significant performance benefits in infrastructure projects and high-stress environments.

Advantages of Microalloyed Steel

Microalloyed steel offers superior strength and toughness compared to conventional steel due to its refined grain structure and controlled microalloying elements like niobium and vanadium. This results in enhanced weldability, improved fatigue resistance, and reduced weight without sacrificing durability, making it ideal for construction and automotive applications. Your projects benefit from cost efficiency and higher performance by using microalloyed steel over traditional steel options.

Limitations and Challenges

Microalloyed steel faces challenges such as higher production costs and sensitivity to precise temperature control during processing, which can limit its widespread use compared to conventional steel. Conventional steel, while more cost-effective, lacks the enhanced strength and toughness of microalloyed variants, often requiring thicker sections or additional treatments for comparable performance. You must weigh these limitations against your project's specific mechanical and economic requirements when selecting the appropriate steel type.

Future Trends in Steel Development

Microalloyed steel is gaining prominence over conventional steel due to its enhanced strength-to-weight ratio and improved weldability, driving innovations in automotive and construction industries. Future trends indicate a shift towards developing ultra-high-strength microalloyed steels with tailored mechanical properties through refined thermo-mechanical processing techniques. Advances in alloying elements like niobium, vanadium, and titanium combined with sustainable production methods are key to meeting the demands for lightweight, energy-efficient, and environmentally friendly steel solutions.

Microalloyed Steel vs Conventional Steel Infographic

libmatt.com

libmatt.com