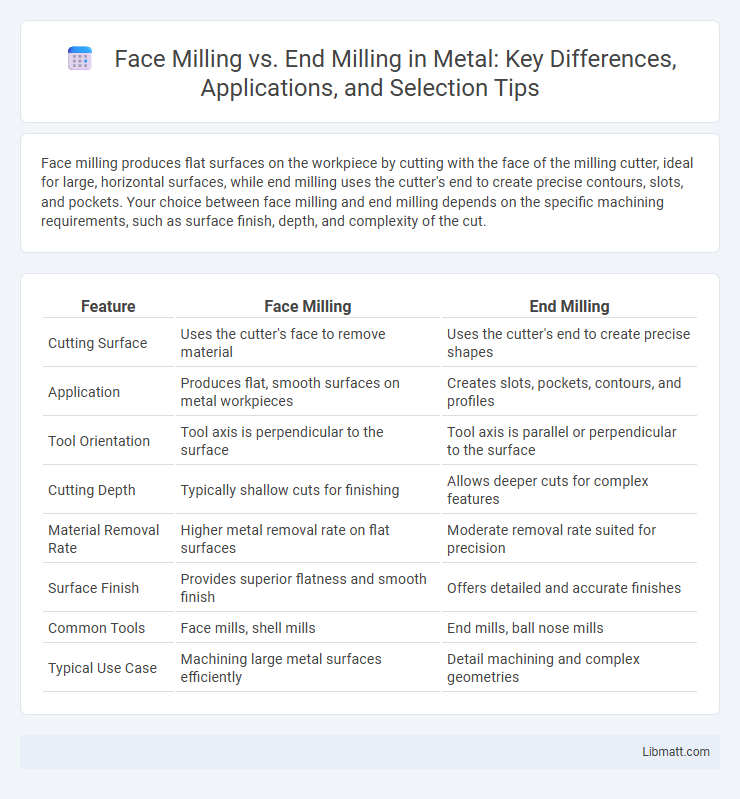

Face milling produces flat surfaces on the workpiece by cutting with the face of the milling cutter, ideal for large, horizontal surfaces, while end milling uses the cutter's end to create precise contours, slots, and pockets. Your choice between face milling and end milling depends on the specific machining requirements, such as surface finish, depth, and complexity of the cut.

Table of Comparison

| Feature | Face Milling | End Milling |

|---|---|---|

| Cutting Surface | Uses the cutter's face to remove material | Uses the cutter's end to create precise shapes |

| Application | Produces flat, smooth surfaces on metal workpieces | Creates slots, pockets, contours, and profiles |

| Tool Orientation | Tool axis is perpendicular to the surface | Tool axis is parallel or perpendicular to the surface |

| Cutting Depth | Typically shallow cuts for finishing | Allows deeper cuts for complex features |

| Material Removal Rate | Higher metal removal rate on flat surfaces | Moderate removal rate suited for precision |

| Surface Finish | Provides superior flatness and smooth finish | Offers detailed and accurate finishes |

| Common Tools | Face mills, shell mills | End mills, ball nose mills |

| Typical Use Case | Machining large metal surfaces efficiently | Detail machining and complex geometries |

Introduction to Face Milling and End Milling

Face milling involves cutting with the face of the milling cutter, producing a flat surface and is ideal for creating broad, smooth finishes on large workpieces. End milling uses the cutter's end to create slots, pockets, or sharp contours, making it suitable for detailed and precise machining tasks. Understanding the differences in cutting geometry and application helps optimize Your machining process for efficiency and surface quality.

Defining Face Milling

Face milling is a machining process where the cutting tool rotates perpendicular to the workpiece surface, primarily removing material from large flat areas. It uses a face mill cutter with multiple cutting edges designed for high-efficiency surface finishing and heavy metal removal. This method contrasts with end milling, which uses a rotating cutter oriented parallel to the workpiece for detailed profiles and slots.

Understanding End Milling

End milling involves cutting with the tool's end face as well as the periphery, making it ideal for producing slots, contours, and complex geometries with high precision. The end mill tool features multiple cutting edges on its periphery and tip, enabling it to machine surfaces that are perpendicular or inclined to the tool axis efficiently. This process excels in achieving fine surface finishes and allows for versatile cutting operations on materials ranging from metals to plastics.

Key Differences Between Face Milling and End Milling

Face milling primarily involves cutting with the face of the milling cutter to create flat surfaces, while end milling uses the cutter's end to produce precise slots, pockets, and profiles. Face milling typically handles larger surface areas with lower precision, whereas end milling delivers finer detail and sharper contours. The choice between face milling and end milling depends on factors like surface finish requirements, material type, and the complexity of the desired geometry.

Typical Applications of Face Milling

Face milling is commonly used for creating flat surfaces, such as in preparing large, rough workpieces for machining or finishing castings and forgings. This method excels in machining wide, smooth faces quickly, making it ideal for applications like removing excess material from steel or aluminum plates in automotive and aerospace manufacturing. Your production efficiency benefits from face milling's capability to deliver consistent surface finishes on broad areas with high feed rates.

Common Uses for End Milling

End milling is commonly used for creating precise slots, contours, and complex 3D shapes on metal and plastic workpieces. It excels in machining intricate profiles, pockets, and surface finishes due to its versatile cutting edge geometry. Typical applications include die and mold manufacturing, aerospace component shaping, and precision engineering tasks requiring detailed surface control.

Tool Design and Geometry Comparison

Face milling tools feature a larger diameter with multiple insert cutters positioned on the face of the tool, optimizing them for high material removal rates and large surface area machining. End milling tools have a smaller diameter with cutting edges on the periphery and tip, allowing for precise contouring, slotting, and profiling in complex geometric shapes. The geometry of face mills typically includes indexable inserts with varying rake angles for heavy-duty cuts, while end mills have helical flutes designed for chip evacuation and versatile cutting directions.

Surface Finish and Material Removal Rates

Face milling delivers superior surface finish by engaging multiple cutting edges simultaneously, producing smoother and more uniform surfaces ideal for large, flat areas. End milling offers greater versatility in contouring and slotting but may result in a rougher finish due to fewer cutting teeth in contact with the workpiece. Material removal rates are generally higher in face milling because of the larger cutter diameter and greater surface engagement, enabling faster machining of extensive surfaces.

Choosing Between Face Milling and End Milling

Choosing between face milling and end milling depends on the desired surface finish, material removal rate, and workpiece geometry. Face milling offers superior surface finish and is ideal for large, flat surfaces due to its ability to use larger cutters and achieve higher material removal rates. End milling provides greater versatility for complex shapes, pockets, and contouring, making it the preferred choice for detailed machining and precision work.

Conclusion: Selecting the Right Milling Technique

Selecting the right milling technique depends on your specific machining goals and material properties. Face milling is ideal for creating flat surfaces and achieving high material removal rates, while end milling excels in precision tasks and complex contouring. Understanding the strengths of each method ensures optimal surface finish and machining efficiency for your project.

Face Milling vs End Milling Infographic

libmatt.com

libmatt.com