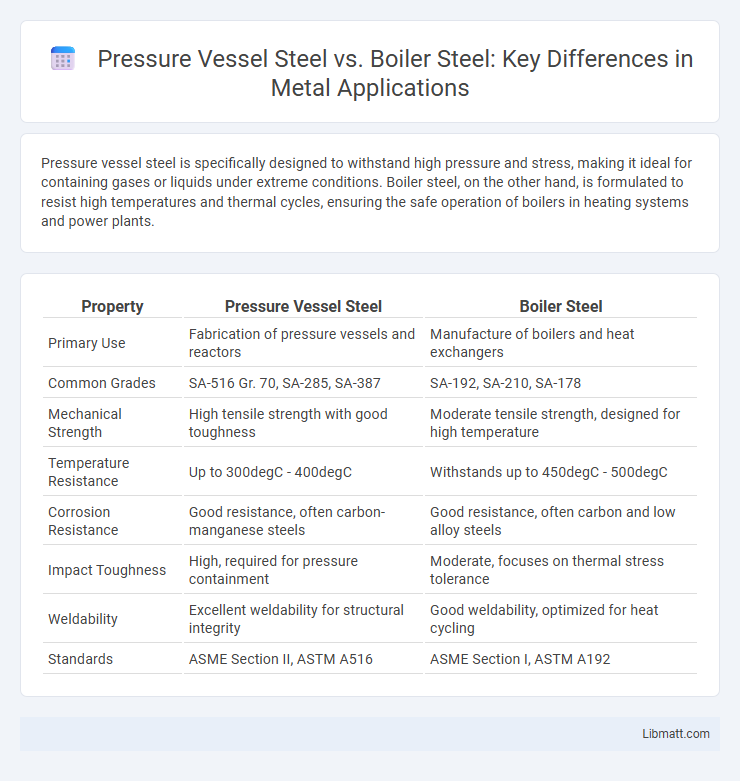

Pressure vessel steel is specifically designed to withstand high pressure and stress, making it ideal for containing gases or liquids under extreme conditions. Boiler steel, on the other hand, is formulated to resist high temperatures and thermal cycles, ensuring the safe operation of boilers in heating systems and power plants.

Table of Comparison

| Property | Pressure Vessel Steel | Boiler Steel |

|---|---|---|

| Primary Use | Fabrication of pressure vessels and reactors | Manufacture of boilers and heat exchangers |

| Common Grades | SA-516 Gr. 70, SA-285, SA-387 | SA-192, SA-210, SA-178 |

| Mechanical Strength | High tensile strength with good toughness | Moderate tensile strength, designed for high temperature |

| Temperature Resistance | Up to 300degC - 400degC | Withstands up to 450degC - 500degC |

| Corrosion Resistance | Good resistance, often carbon-manganese steels | Good resistance, often carbon and low alloy steels |

| Impact Toughness | High, required for pressure containment | Moderate, focuses on thermal stress tolerance |

| Weldability | Excellent weldability for structural integrity | Good weldability, optimized for heat cycling |

| Standards | ASME Section II, ASTM A516 | ASME Section I, ASTM A192 |

Introduction to Pressure Vessel Steel and Boiler Steel

Pressure vessel steel and boiler steel are specialized materials designed to withstand high pressure and temperature conditions in industrial applications. Pressure vessel steel, commonly conforming to ASTM A516 Grade 70, offers excellent toughness and resistance to cracking for constructing containers like reactors and storage tanks. Boiler steel, such as ASTM A178 or A192, is engineered for high-temperature durability and corrosion resistance, ensuring safe and efficient operation in steam boilers and heat exchangers.

Key Differences Between Pressure Vessel Steel and Boiler Steel

Pressure vessel steel is specifically engineered to withstand high pressure and temperature conditions with superior tensile strength and toughness, while boiler steel is designed primarily for heat resistance and corrosion protection in steam boilers. Pressure vessel steel often contains higher alloy content and improved microstructure to handle stress and fatigue, whereas boiler steel prioritizes thermal conductivity and oxidation resistance. These key differences impact their applications, with pressure vessel steel ideal for storage tanks and reactors, and boiler steel suited for boiler tubes and heat exchangers.

Chemical Composition Comparison

Pressure vessel steel typically contains higher percentages of manganese and silicon to enhance strength and toughness under high pressure, whereas boiler steel often has increased carbon content to improve heat resistance and weldability. Both steels include controlled levels of sulfur and phosphorus to minimize brittleness, but pressure vessel steel usually mandates stricter limits to ensure better ductility and impact resistance. The specific alloying elements such as chromium, molybdenum, and nickel vary depending on standards like ASTM A516 for pressure vessels and ASTM A285 for boilers, reflecting their distinct operational requirements.

Mechanical Properties and Performance

Pressure vessel steel exhibits superior tensile strength and toughness to withstand high internal pressures and dynamic loading, while boiler steel is optimized for high-temperature resistance and creep strength to endure prolonged heat exposure. Pressure vessel steel often includes alloying elements like manganese and vanadium, enhancing its impact resistance and fatigue life, whereas boiler steel prioritizes chromium and molybdenum for improved oxidation and corrosion resistance under thermal stress. Both materials demonstrate excellent weldability, but pressure vessel steel emphasizes ductility to prevent brittle fracture, whereas boiler steel focuses on maintaining structural integrity at elevated temperatures.

Standards and Certification Requirements

Pressure vessel steel and boiler steel must comply with stringent standards such as ASME Section II and ASTM specifications to guarantee safety and performance under high pressure and temperature conditions. Certification requirements typically include material traceability, impact testing, and mechanical property verification to meet industry regulations like EN 13445 for pressure vessels and ASME BPVC for boilers. Your choice between these steels should prioritize adherence to these standards to ensure reliability and regulatory compliance in critical applications.

Typical Applications in Industry

Pressure vessel steel is primarily used for manufacturing storage tanks, reactors, and large diameter pipes designed to withstand high pressure in chemical, oil, and gas industries. Boiler steel is specifically engineered for constructing boilers, superheaters, and heat exchangers, where high temperature resistance and thermal fatigue strength are critical in power generation and steam production. Your choice depends on the operating conditions and safety standards required in applications such as petrochemical plants or industrial heating systems.

Fabrication and Weldability Considerations

Pressure vessel steel requires stringent fabrication techniques and high weldability standards to withstand extreme pressure and prevent catastrophic failure, often involving specialized welding processes like submerged arc welding. Boiler steel, while also demanding good weldability, focuses on resistances to high temperature and corrosion, requiring fabrication methods that accommodate thermal expansion and cyclic stress. Your choice between these steels should consider the specific application environment and the compatibility of welding procedures with the mechanical properties of each steel type.

Corrosion Resistance and Durability

Pressure vessel steel offers superior corrosion resistance due to its alloy composition, including chromium and molybdenum, which enhance its ability to withstand harsh industrial environments. Boiler steel, typically carbon steel with lower alloy content, presents moderate corrosion resistance but requires additional treatments or coatings to improve durability under high-temperature steam conditions. The enhanced durability of pressure vessel steel ensures longer service life and reduced maintenance in corrosive applications compared to standard boiler steel.

Cost and Availability Factors

Pressure vessel steel typically has higher costs due to stringent specifications and certification requirements ensuring safety under high pressure, while boiler steel tends to be more readily available and cost-effective for standard applications. Your choice between the two should consider the critical nature of the application, as pressure vessel steel demands premium pricing but offers enhanced performance and compliance. Availability varies by region and supplier, with boiler steel generally accessible in larger quantities for common use.

Choosing the Right Steel for Your Project

Choosing the right steel for your project depends on understanding the specific requirements of pressure vessel steel and boiler steel, as pressure vessel steel offers high tensile strength and excellent toughness to withstand extreme internal pressures. Boiler steel, designed to endure high temperatures and corrosion from steam, provides enhanced resistance to thermal fatigue and scaling. Your selection should align with operating conditions, including temperature, pressure, and environmental factors, to ensure safety, durability, and performance.

Pressure Vessel Steel vs Boiler Steel Infographic

libmatt.com

libmatt.com