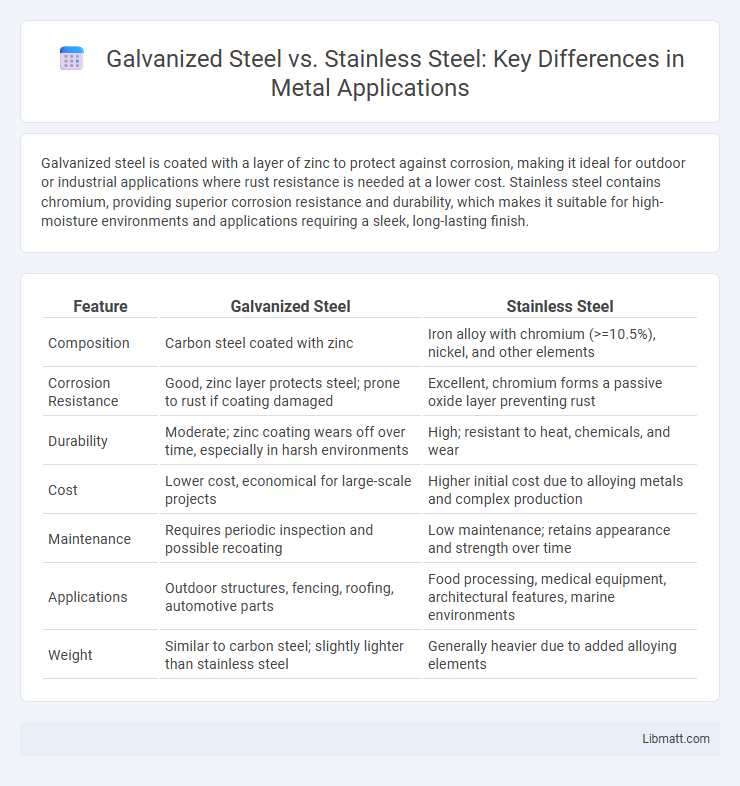

Galvanized steel is coated with a layer of zinc to protect against corrosion, making it ideal for outdoor or industrial applications where rust resistance is needed at a lower cost. Stainless steel contains chromium, providing superior corrosion resistance and durability, which makes it suitable for high-moisture environments and applications requiring a sleek, long-lasting finish.

Table of Comparison

| Feature | Galvanized Steel | Stainless Steel |

|---|---|---|

| Composition | Carbon steel coated with zinc | Iron alloy with chromium (>=10.5%), nickel, and other elements |

| Corrosion Resistance | Good, zinc layer protects steel; prone to rust if coating damaged | Excellent, chromium forms a passive oxide layer preventing rust |

| Durability | Moderate; zinc coating wears off over time, especially in harsh environments | High; resistant to heat, chemicals, and wear |

| Cost | Lower cost, economical for large-scale projects | Higher initial cost due to alloying metals and complex production |

| Maintenance | Requires periodic inspection and possible recoating | Low maintenance; retains appearance and strength over time |

| Applications | Outdoor structures, fencing, roofing, automotive parts | Food processing, medical equipment, architectural features, marine environments |

| Weight | Similar to carbon steel; slightly lighter than stainless steel | Generally heavier due to added alloying elements |

Introduction to Galvanized Steel and Stainless Steel

Galvanized steel is carbon steel coated with a layer of zinc to protect against corrosion, making it ideal for outdoor and industrial applications where durability is essential. Stainless steel contains chromium and other alloying elements, providing excellent resistance to rust, heat, and chemical damage, often used in kitchen appliances and medical equipment. Understanding the differences in composition and protective qualities helps you choose the right material for your specific project needs.

Composition and Material Differences

Galvanized steel consists of carbon steel coated with a layer of zinc to protect against corrosion, whereas stainless steel is an alloy primarily composed of iron, chromium (at least 10.5%), and often nickel, providing inherent resistance to rust and staining. The zinc coating on galvanized steel acts as a sacrificial barrier, preventing rust through galvanic protection, while stainless steel's chromium forms a passive oxide layer that blocks oxidation. These fundamental differences in composition influence their durability, maintenance, and application environments, with stainless steel offering superior corrosion resistance in harsh or acidic conditions.

Corrosion Resistance Comparison

Galvanized steel features a zinc coating that provides effective protection against rust, especially in outdoor and moist environments, by acting as a sacrificial layer. Stainless steel, composed of chromium and nickel alloys, offers superior corrosion resistance by forming a passive oxide layer that prevents surface degradation even in harsh chemical or marine conditions. While galvanized steel is cost-effective for moderate corrosion exposure, stainless steel remains the preferred choice for long-term durability and resistance to pitting, staining, and extreme environmental factors.

Strength and Durability

Galvanized steel offers robust corrosion resistance due to its zinc coating, making it durable for outdoor and industrial applications, though the coating can wear over time under harsh conditions. Stainless steel provides superior strength and long-lasting durability with its chromium-alloy composition, resisting rust and maintaining structural integrity even in extreme environments. For projects demanding high tensile strength and minimal maintenance, stainless steel is often the preferred choice over galvanized steel.

Cost and Affordability

Galvanized steel is typically more cost-effective than stainless steel due to its lower raw material costs and simpler manufacturing process. Stainless steel, while offering superior corrosion resistance and durability, commands a higher price point because of the added chromium and nickel alloys. For budget-sensitive projects, galvanized steel provides an affordable solution with adequate protection against rust in less demanding environments.

Applications and Common Uses

Galvanized steel is widely used in construction, automotive parts, and outdoor structures due to its corrosion-resistant zinc coating that protects it from rust in harsh environments. Stainless steel is preferred in medical instruments, kitchen appliances, and chemical processing equipment because of its superior resistance to corrosion, heat, and staining. Both materials are essential in manufacturing but are selected based on exposure conditions and durability requirements.

Maintenance Requirements

Galvanized steel requires regular inspection to monitor zinc coating integrity and protect against rust through prompt touch-ups or re-galvanizing. Stainless steel demands less maintenance due to its chromium oxide layer, which naturally resists corrosion and staining, making it ideal for environments with moisture or chemicals. Choosing stainless steel can reduce your long-term maintenance costs and effort compared to galvanized steel.

Environmental Impact and Sustainability

Galvanized steel, coated with a layer of zinc to prevent corrosion, requires less energy in production compared to stainless steel, making it a more energy-efficient option. Stainless steel, composed mainly of iron, chromium, and nickel, offers superior durability and recyclability, with nearly 100% of stainless steel being recyclable, which contributes to its sustainability. Your choice between galvanized and stainless steel should consider the balance between lower initial environmental impact and long-term recyclability.

Aesthetic Differences

Galvanized steel features a matte gray finish with a spangled pattern due to its zinc coating, offering a rugged, industrial look often preferred in outdoor or utilitarian applications. Stainless steel presents a smooth, shiny, and reflective surface that maintains a clean and modern aesthetic, suitable for architectural and decorative purposes. The visual appeal of stainless steel is enhanced by its corrosion resistance and ease of polishing, while galvanized steel's finish can dull over time with exposure to weather.

Choosing the Right Material: Factors to Consider

Galvanized steel offers superior corrosion resistance due to its zinc coating, making it ideal for outdoor applications exposed to moisture, while stainless steel provides enhanced durability and aesthetic appeal with its alloy composition containing chromium. Factors such as environmental exposure, budget constraints, maintenance requirements, and desired lifespan play critical roles in material selection. Evaluating the specific use case and conditions ensures optimal performance and cost-effectiveness between galvanized and stainless steel options.

galvanized steel vs stainless steel Infographic

libmatt.com

libmatt.com