Mild steel offers excellent weldability and machinability, making it ideal for construction and general manufacturing, while tool steel provides superior hardness and wear resistance, perfect for cutting tools and dies. Choosing the right material depends on your specific application requirements, balancing cost, strength, and durability.

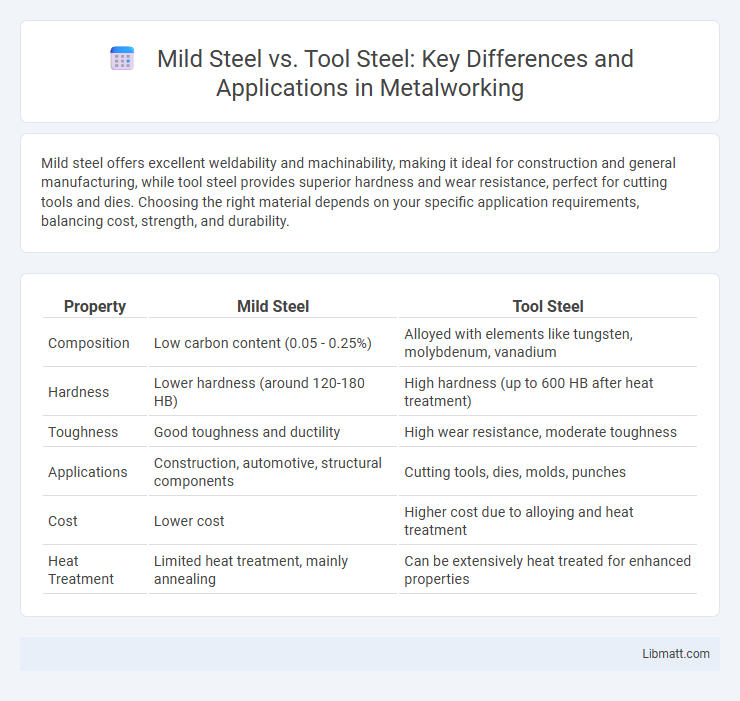

Table of Comparison

| Property | Mild Steel | Tool Steel |

|---|---|---|

| Composition | Low carbon content (0.05 - 0.25%) | Alloyed with elements like tungsten, molybdenum, vanadium |

| Hardness | Lower hardness (around 120-180 HB) | High hardness (up to 600 HB after heat treatment) |

| Toughness | Good toughness and ductility | High wear resistance, moderate toughness |

| Applications | Construction, automotive, structural components | Cutting tools, dies, molds, punches |

| Cost | Lower cost | Higher cost due to alloying and heat treatment |

| Heat Treatment | Limited heat treatment, mainly annealing | Can be extensively heat treated for enhanced properties |

Introduction to Mild Steel and Tool Steel

Mild steel is a low-carbon alloy known for its ductility, weldability, and affordability, making it ideal for general construction and manufacturing. Tool steel contains higher carbon and alloying elements, offering superior hardness, wear resistance, and strength, essential for cutting, machining, and tooling applications. Understanding the differences helps you select the right material based on strength and durability requirements.

Chemical Composition Differences

Mild steel primarily consists of iron with carbon content around 0.05% to 0.25%, making it soft and ductile, whereas tool steel contains higher carbon content, typically between 0.5% and 1.5%, along with elements like tungsten, molybdenum, chromium, and vanadium for enhanced hardness and wear resistance. The alloying elements in tool steel contribute to its superior strength and durability, suitable for cutting, shaping, and machining applications, unlike mild steel which is used for general structural purposes. Understanding these chemical composition differences helps you select the right steel type based on the mechanical properties and performance required for your project.

Mechanical Properties Comparison

Mild steel offers lower tensile strength and hardness compared to tool steel, making it more ductile and easier to weld or machine, which suits applications requiring flexibility and formability. Tool steel exhibits superior wear resistance, higher hardness, and better tensile strength due to its alloying elements like tungsten, chromium, and vanadium, making it ideal for cutting tools, dies, and molds. Your choice between mild steel and tool steel depends on whether your application prioritizes mechanical durability or ease of fabrication.

Common Applications of Mild Steel

Mild steel is widely used in construction, automotive manufacturing, and structural engineering due to its excellent weldability, ductility, and cost-effectiveness. Common applications include building frames, pipelines, shipbuilding, and automotive body panels, where high strength and flexibility are required without specialized hardness or wear resistance. Its ability to be easily machined and formed makes it ideal for general-purpose tools, structural components, and everyday metal fabrication projects.

Typical Uses for Tool Steel

Tool steel is primarily used in manufacturing cutting tools, dies, and molds due to its high hardness, wear resistance, and ability to retain a sharp edge at elevated temperatures. It is ideal for applications requiring precision and durability, such as stamping, punching, and machining operations. Your choice of tool steel ensures enhanced performance and longevity in demanding industrial environments.

Hardness and Strength Comparison

Tool steel exhibits significantly higher hardness and tensile strength compared to mild steel, making it ideal for cutting and machining applications. Mild steel typically has a hardness of 120-180 BHN (Brinell Hardness Number) and tensile strength around 400-550 MPa, whereas tool steel hardness can exceed 600 BHN with tensile strength surpassing 1000 MPa. The enhanced carbon and alloy content in tool steel contribute to its superior wear resistance and durability under high-stress conditions.

Workability and Machinability

Mild steel offers superior workability due to its lower carbon content, making it easier to cut, shape, and weld compared to tool steel. Tool steel, characterized by higher hardness and wear resistance, exhibits reduced machinability and requires specialized tools and techniques for processing. Selecting between mild steel and tool steel depends on balancing ease of fabrication with the application's strength and durability requirements.

Cost and Availability

Mild steel is generally more cost-effective and widely available compared to tool steel, making it a preferred choice for large-scale manufacturing and everyday applications. Tool steel, with its higher alloy content and specialized properties, tends to be more expensive and less readily found in standard supply channels. Your selection depends on balancing budget constraints with the need for enhanced durability and performance in specific industrial tasks.

Corrosion Resistance and Durability

Mild steel offers moderate corrosion resistance but is prone to rust if not properly coated or maintained, making it less durable in harsh environments. Tool steel contains higher carbon and alloy elements like chromium and vanadium, significantly enhancing its corrosion resistance and overall durability under high stress and wear conditions. The alloy composition in tool steel provides superior hardness and resistance to deformation compared to mild steel, ensuring longer lifespan in demanding applications.

Choosing the Right Steel for Your Project

Selecting the right steel for your project depends on factors such as strength, wear resistance, and machinability. Mild steel offers excellent ductility and weldability, making it ideal for general construction and fabrication tasks, while tool steel provides superior hardness and heat resistance suited for cutting tools, molds, and dies. Understanding specific project requirements ensures optimal performance and longevity by matching mild steel's flexibility or tool steel's toughness accordingly.

Mild Steel vs Tool Steel Infographic

libmatt.com

libmatt.com