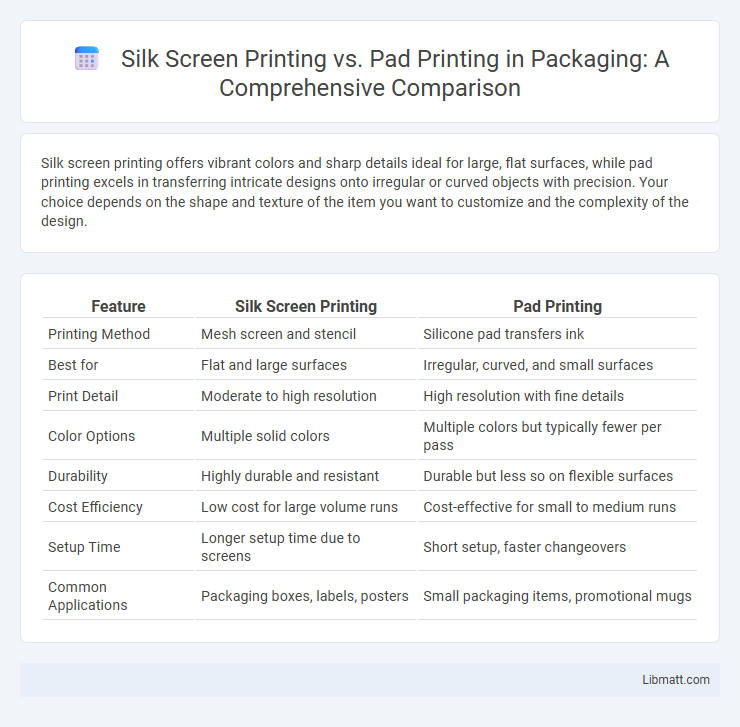

Silk screen printing offers vibrant colors and sharp details ideal for large, flat surfaces, while pad printing excels in transferring intricate designs onto irregular or curved objects with precision. Your choice depends on the shape and texture of the item you want to customize and the complexity of the design.

Table of Comparison

| Feature | Silk Screen Printing | Pad Printing |

|---|---|---|

| Printing Method | Mesh screen and stencil | Silicone pad transfers ink |

| Best for | Flat and large surfaces | Irregular, curved, and small surfaces |

| Print Detail | Moderate to high resolution | High resolution with fine details |

| Color Options | Multiple solid colors | Multiple colors but typically fewer per pass |

| Durability | Highly durable and resistant | Durable but less so on flexible surfaces |

| Cost Efficiency | Low cost for large volume runs | Cost-effective for small to medium runs |

| Setup Time | Longer setup time due to screens | Short setup, faster changeovers |

| Common Applications | Packaging boxes, labels, posters | Small packaging items, promotional mugs |

Introduction to Silk Screen Printing and Pad Printing

Silk screen printing utilizes a mesh stencil to transfer ink onto a substrate, excelling in producing vibrant colors and detailed designs on flat or slightly curved surfaces. Pad printing employs a silicone pad to pick up ink from an etched plate and transfer it onto irregular or complex surfaces, making it ideal for printing on three-dimensional objects. Both methods cater to different production needs, with silk screen printing favored for larger runs and pad printing for detailed applications on smaller items.

Key Principles of Silk Screen Printing

Silk screen printing operates on the principle of pushing ink through a fine mesh screen stencil to create a design on a substrate, allowing for vibrant colors and detailed patterns. The process involves preparing a screen with a photosensitive emulsion that blocks ink in non-image areas, ensuring precise ink transfer only where the design is intended. This technique excels in producing high-quality, durable prints on flat or slightly curved surfaces, making it ideal for textiles, posters, and promotional items.

Core Features of Pad Printing

Pad printing uses a silicone pad to transfer ink onto irregular or curved surfaces, making it ideal for printing on three-dimensional objects. This printing method offers high precision and can reproduce fine details, with the capability to print on materials like metal, glass, and plastic. Your choice of pad printing ensures versatile customization on challenging substrates where silk screen printing may struggle.

Application Areas: Where Each Technique Excels

Silk screen printing excels in producing vibrant, durable designs on flat or slightly curved surfaces such as textiles, posters, and large promotional items, making it ideal for apparel and signage. Pad printing is best suited for printing on irregular, three-dimensional objects like electronic gadgets, medical devices, and promotional products with complex shapes, enabling precise image transfer onto challenging surfaces. Choosing the right method ensures your print quality and application area meet specific project requirements efficiently.

Surface Compatibility and Materials

Silk screen printing excels on flat, rigid surfaces such as textiles, paper, glass, and metal, offering bold, vibrant prints on materials like cotton and polyester. Pad printing is ideal for printing on irregular, curved, or textured surfaces, including plastics, ceramics, and electronics, due to its flexible silicone pad that adapts to various shapes. Understanding your project's surface compatibility ensures you select the best printing method to achieve high-quality, durable results.

Image Detail and Print Quality Comparison

Silk screen printing delivers high-resolution images with sharp edges and vibrant colors, making it ideal for large, flat surfaces requiring detailed designs. Pad printing excels in transferring fine, intricate details onto irregular, curved, or small surfaces, providing precise image reproduction on complex shapes. While silk screen printing offers superior color saturation, pad printing achieves better adaptability for detailed prints on three-dimensional objects.

Production Speed and Efficiency

Silk screen printing offers higher production speed for large-volume runs due to its ability to print multiple items simultaneously with consistent quality. Pad printing excels in efficiency for intricate designs on irregular or small surfaces, reducing setup time for varied prints. Your choice depends on whether you prioritize rapid bulk printing (silk screen) or detailed, precise applications on complex shapes (pad printing).

Cost Considerations: Setup and Maintenance

Silk screen printing involves higher initial setup costs due to the creation of screens for each design, making it more cost-effective for large production runs. Pad printing requires less expensive setup since it uses etched plates, suitable for smaller batches and intricate designs on irregular surfaces. Maintenance expenses tend to be higher in silk screen printing because of screen cleaning and replacement, whereas pad printing demands regular upkeep of pads and plates but generally incurs lower ongoing costs.

Durability and Longevity of Prints

Silk screen printing offers exceptional durability due to its thick ink layers that resist fading and wear, making it ideal for long-lasting prints on textiles and large surfaces. Pad printing provides fine detail and can print on irregular or small surfaces, but its prints tend to be less durable and more prone to wear over time. Your choice between the two should consider the required print longevity and surface type for optimal results.

Selecting the Right Printing Method for Your Project

Silk screen printing offers high durability and vibrant colors ideal for large, flat surfaces and bulk production, while pad printing excels at printing on irregular or curved objects with fine detail. Choosing the right method depends on your project's material, surface complexity, quantity, and color requirements to achieve optimal results. Evaluate factors like print area size, substrate type, and production volume to determine whether silk screen or pad printing best meets your needs.

Silk screen printing vs pad printing Infographic

libmatt.com

libmatt.com