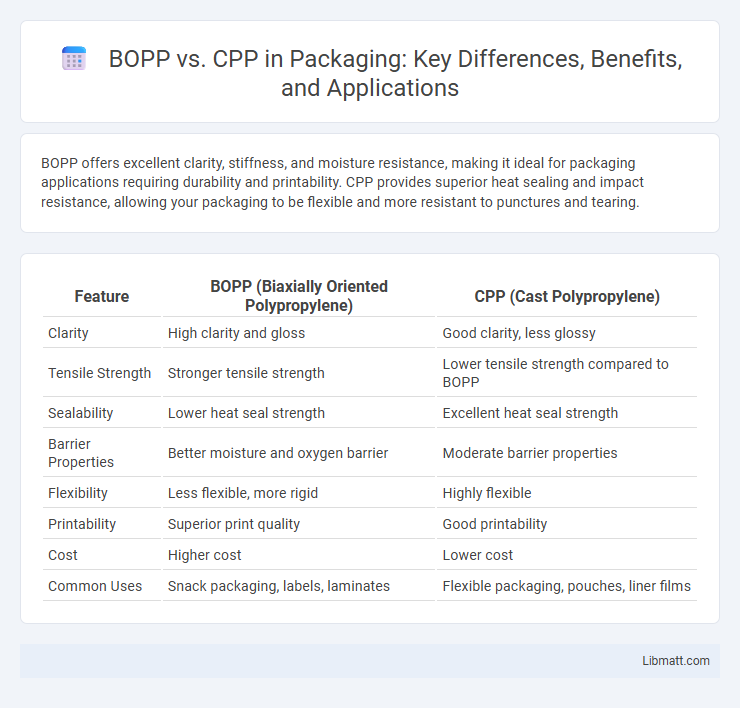

BOPP offers excellent clarity, stiffness, and moisture resistance, making it ideal for packaging applications requiring durability and printability. CPP provides superior heat sealing and impact resistance, allowing your packaging to be flexible and more resistant to punctures and tearing.

Table of Comparison

| Feature | BOPP (Biaxially Oriented Polypropylene) | CPP (Cast Polypropylene) |

|---|---|---|

| Clarity | High clarity and gloss | Good clarity, less glossy |

| Tensile Strength | Stronger tensile strength | Lower tensile strength compared to BOPP |

| Sealability | Lower heat seal strength | Excellent heat seal strength |

| Barrier Properties | Better moisture and oxygen barrier | Moderate barrier properties |

| Flexibility | Less flexible, more rigid | Highly flexible |

| Printability | Superior print quality | Good printability |

| Cost | Higher cost | Lower cost |

| Common Uses | Snack packaging, labels, laminates | Flexible packaging, pouches, liner films |

Introduction to BOPP and CPP Films

BOPP (Biaxially Oriented Polypropylene) and CPP (Cast Polypropylene) films are widely used in packaging due to their distinct properties. BOPP films offer high tensile strength, excellent clarity, and superior moisture resistance, making them ideal for labeling and protective applications. CPP films provide greater heat sealability and flexibility, serving as efficient liners or lamination layers to enhance packaging performance for your products.

Composition and Manufacturing Processes

BOPP (Biaxially Oriented Polypropylene) is produced by stretching polypropylene film in both machine and transverse directions, enhancing tensile strength, clarity, and barrier properties, while CPP (Cast Polypropylene) is made by extruding molten polypropylene onto a chill roll and solidifying it rapidly, resulting in a softer, more flexible film with excellent heat sealability. BOPP's orientation process provides improved mechanical properties and dimensional stability compared to the non-oriented, amorphous structure of CPP. The manufacturing differences impact their typical applications, with BOPP favored for packaging requiring stiffness and gloss, and CPP preferred for applications demanding flexibility and a lower sealing temperature.

Key Physical Properties Comparison

Biaxially Oriented Polypropylene (BOPP) offers superior tensile strength and stiffness compared to Cast Polypropylene (CPP), making it ideal for packaging requiring durability and clarity. CPP exhibits better heat sealability and higher elongation at break, providing enhanced flexibility and impact resistance for applications needing strong seals and toughness. When selecting your packaging material, consider BOPP for rigidity and optical clarity, while CPP suits flexible wrapping and heat sealing needs.

Barrier Performance: Moisture and Gas

BOPP (Biaxially Oriented Polypropylene) films offer moderate moisture barrier properties with water vapor transmission rates (WVTR) typically ranging from 30 to 60 g/m2/day, suitable for packaging applications requiring breathability. CPP (Cast Polypropylene) films provide lower moisture barrier performance compared to BOPP, with higher WVTR values but exhibit superior flexibility and heat resistance. Both materials demonstrate limited gas barrier capabilities, necessitating the use of additional coatings or laminates when enhanced oxygen or aroma barrier performance is essential in packaging.

Printability and Surface Treatment

BOPP (Biaxially Oriented Polypropylene) offers superior printability due to its smooth surface and excellent clarity, making it ideal for high-quality graphics and vibrant colors. CPP (Cast Polypropylene), while having good clarity, requires surface treatments like corona or flame treatment to enhance ink adhesion and print performance. To ensure your packaging stands out, selecting BOPP can reduce the need for extensive surface treatment while providing crisp, durable prints.

Applications in Packaging Industries

BOPP (Biaxially Oriented Polypropylene) films are widely used in packaging industries for applications requiring high clarity, gloss, and excellent moisture barrier properties, such as snack food wrappers, labels, and lamination films. CPP (Cast Polypropylene) films offer superior heat seal strength and flexibility, making them ideal for packaging applications like flow wrap, pillow bags, and heavy-duty packaging where durability and performance under stress are critical. The choice between BOPP and CPP depends on packaging needs, balancing factors like transparency, sealability, and mechanical strength.

Cost Efficiency Analysis

BOPP (Biaxially Oriented Polypropylene) offers superior cost efficiency due to its lower raw material cost and higher yield per kilogram compared to CPP (Cast Polypropylene), resulting in reduced overall packaging expenses. CPP provides better heat sealability and flexibility but typically incurs higher production costs because of slower processing speeds and greater energy consumption. Businesses prioritizing budget-conscious packaging often prefer BOPP for its balance of performance and affordability, especially in high-volume applications.

Environmental Impact and Recyclability

BOPP (Biaxially Oriented Polypropylene) and CPP (Cast Polypropylene) differ significantly in environmental impact and recyclability; BOPP films are lightweight and have lower carbon footprints due to their thinner gauge and higher strength, making them more energy-efficient in production. CPP films are favored for their heat resistance but tend to consume more resources and are less commonly recycled because of mixed polymer use and contamination risks. Recycling infrastructure is more established for BOPP, which supports improved circularity and reduced landfill waste in flexible packaging applications.

Choosing Between BOPP and CPP Films

Choosing between BOPP and CPP films depends on your packaging needs; BOPP offers excellent clarity, stiffness, and moisture resistance, making it ideal for printed labels and food packaging. CPP film provides superior heat sealability, flexibility, and impact resistance, perfect for applications requiring high durability and heat sealing. Evaluating your product's protection requirements, sealing methods, and desired aesthetics will help you decide which film optimizes your packaging performance.

Future Trends in Polypropylene Film Packaging

BOPP (Biaxially Oriented Polypropylene) and CPP (Cast Polypropylene) films are evolving with innovations targeting enhanced barrier properties, sustainability, and recyclability to meet future packaging demands. Advances in multi-layer coextrusion and bio-based polypropylene are driving the market towards eco-friendly, lightweight, and high-performance films suitable for food safety and extended shelf life. The integration of smart packaging features, such as antimicrobial coatings and improved printability, is expected to shape the next generation of polypropylene film packaging technologies.

BOPP vs CPP Infographic

libmatt.com

libmatt.com