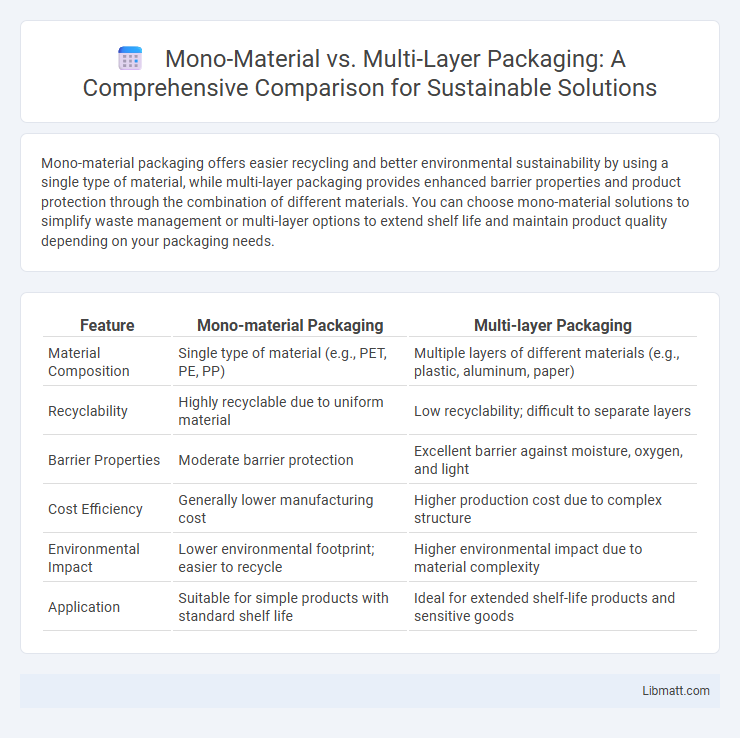

Mono-material packaging offers easier recycling and better environmental sustainability by using a single type of material, while multi-layer packaging provides enhanced barrier properties and product protection through the combination of different materials. You can choose mono-material solutions to simplify waste management or multi-layer options to extend shelf life and maintain product quality depending on your packaging needs.

Table of Comparison

| Feature | Mono-material Packaging | Multi-layer Packaging |

|---|---|---|

| Material Composition | Single type of material (e.g., PET, PE, PP) | Multiple layers of different materials (e.g., plastic, aluminum, paper) |

| Recyclability | Highly recyclable due to uniform material | Low recyclability; difficult to separate layers |

| Barrier Properties | Moderate barrier protection | Excellent barrier against moisture, oxygen, and light |

| Cost Efficiency | Generally lower manufacturing cost | Higher production cost due to complex structure |

| Environmental Impact | Lower environmental footprint; easier to recycle | Higher environmental impact due to material complexity |

| Application | Suitable for simple products with standard shelf life | Ideal for extended shelf-life products and sensitive goods |

Introduction to Packaging Materials

Mono-material packaging consists of a single type of material, such as polyethylene or polypropylene, which enhances recyclability by simplifying the sorting process. Multi-layer packaging combines different materials like plastic, aluminum, and paper to provide superior barrier protection, extending product shelf life but complicating recycling efforts. Your choice between these packaging types impacts environmental sustainability and regulatory compliance, influencing both cost and consumer perception.

What is Mono-Material Packaging?

Mono-material packaging consists of a single type of material, such as polyethylene or polypropylene, designed for ease of recycling and environmental sustainability. This packaging solution enhances material recovery efficiency, reducing contamination in recycling streams compared to multi-layer packaging, which combines different materials like plastic, aluminum, and paper. You can improve your product's eco-friendliness by opting for mono-material packaging, supporting circular economy initiatives.

Understanding Multi-Layer Packaging

Multi-layer packaging combines different materials such as plastic, aluminum, and paper to create barriers that enhance product protection against moisture, oxygen, and light, extending shelf life significantly. Its complex structure, designed for specific functional properties like durability and freshness retention, often poses challenges for recycling due to the difficulty in separating layers. Innovations in recyclable and compostable multi-layer packaging materials are emerging, aiming to balance product safety with environmental sustainability.

Key Differences: Mono-Material vs Multi-Layer

Mono-material packaging consists of a single type of material, such as polyethylene or polypropylene, offering simpler recycling and improved sustainability. Multi-layer packaging combines different materials like plastic, aluminum, and paper to enhance barrier properties and product protection but poses challenges in recycling due to material separation. Your choice depends on balancing environmental impact with functional requirements like durability and shelf life.

Environmental Impact Comparison

Mono-material packaging significantly reduces environmental impact by enhancing recyclability and minimizing resource consumption during production, as it is composed of a single type of material that can be efficiently processed in recycling facilities. In contrast, multi-layer packaging, often made from combinations of plastic, aluminum, and paper, complicates recycling efforts due to the difficulty in separating layers, leading to higher landfill rates and increased environmental pollution. Your choice of mono-material packaging supports circular economy principles by facilitating material recovery and reducing carbon footprint across the product lifecycle.

Recycling and End-of-Life Solutions

Mono-material packaging offers superior recyclability due to its uniform composition, enabling streamlined sorting and processing in recycling facilities. Multi-layer packaging, while providing enhanced barrier properties, often challenges recycling efforts because diverse materials must be separated, complicating end-of-life management. Choosing mono-material solutions supports your sustainability goals by facilitating more efficient recycling and reducing environmental impact.

Performance and Product Protection

Mono-material packaging offers excellent recyclability while maintaining adequate barrier properties to protect products from moisture, oxygen, and contaminants. Multi-layer packaging excels in performance by combining different materials to provide superior barrier protection, extending shelf life and safeguarding sensitive products. However, the complexity of multi-layer structures can complicate recycling processes, impacting sustainability despite enhanced product protection.

Cost Considerations

Mono-material packaging typically reduces production and recycling costs due to its simplified structure and compatibility with standard recycling streams. Multi-layer packaging often incurs higher expenses because of complex material combinations that require advanced manufacturing processes and specialized recycling facilities. Choosing mono-material packaging can lower Your overall packaging costs while enhancing sustainability efforts.

Market Trends and Innovations

Market trends in packaging reveal a growing preference for mono-material solutions due to their superior recyclability and compliance with increasing environmental regulations, driving innovation in barrier performance and material durability. Multi-layer packaging maintains demand for complex barrier properties, leveraging advancements in layer adhesion and sustainable coatings to reduce environmental impact while preserving product quality. Innovations such as biodegradable mono-material films and recyclable multi-layer composites are accelerating adoption amidst rising consumer and legislative pressure for sustainable packaging.

Choosing the Right Packaging Solution

Choosing the right packaging solution depends on balancing factors like sustainability, product protection, and cost efficiency. Mono-material packaging offers easier recyclability and aligns with circular economy goals, while multi-layer packaging provides superior barrier properties for extended shelf life and product safety. Evaluating Your product requirements and environmental impact priorities helps determine the optimal packaging choice.

Mono-material vs multi-layer packaging Infographic

libmatt.com

libmatt.com