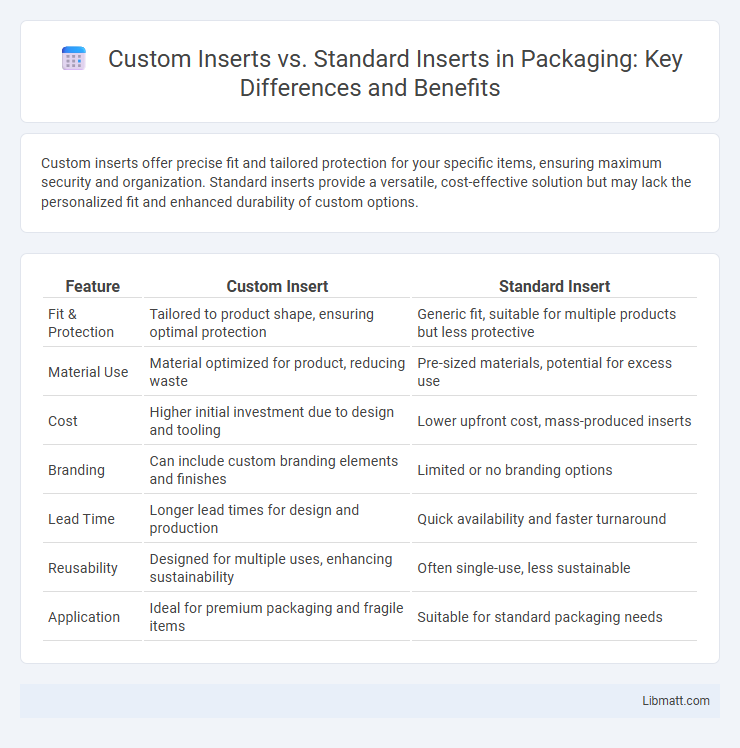

Custom inserts offer precise fit and tailored protection for your specific items, ensuring maximum security and organization. Standard inserts provide a versatile, cost-effective solution but may lack the personalized fit and enhanced durability of custom options.

Table of Comparison

| Feature | Custom Insert | Standard Insert |

|---|---|---|

| Fit & Protection | Tailored to product shape, ensuring optimal protection | Generic fit, suitable for multiple products but less protective |

| Material Use | Material optimized for product, reducing waste | Pre-sized materials, potential for excess use |

| Cost | Higher initial investment due to design and tooling | Lower upfront cost, mass-produced inserts |

| Branding | Can include custom branding elements and finishes | Limited or no branding options |

| Lead Time | Longer lead times for design and production | Quick availability and faster turnaround |

| Reusability | Designed for multiple uses, enhancing sustainability | Often single-use, less sustainable |

| Application | Ideal for premium packaging and fragile items | Suitable for standard packaging needs |

Understanding Custom Inserts vs Standard Inserts

Custom inserts offer tailored solutions designed to fit specific product dimensions and unique branding needs, enhancing protection and presentation. In contrast, standard inserts utilize pre-made shapes and sizes, providing cost-effective and quick packaging options suitable for common products. Choosing between custom and standard inserts depends on balancing product protection, aesthetic appeal, and budget constraints.

Key Differences Between Custom and Standard Inserts

Custom inserts are designed specifically to meet unique specifications or fit uncommon dimensions, offering tailored protection and organization for your items. Standard inserts come in pre-defined sizes and shapes, providing a cost-effective and quick solution but with limited flexibility. Choosing between custom and standard inserts depends on your need for precise fit versus budget and availability.

Benefits of Custom Inserts

Custom inserts provide superior protection by perfectly fitting the dimensions and contours of specific items, minimizing movement and potential damage during transportation or storage. They enhance organization and presentation, ensuring each component is securely housed and easily accessible, which streamlines inventory management and improves user experience. Custom inserts can also be designed with specialized materials that offer better cushioning, durability, and aesthetic appeal compared to standard inserts.

Advantages of Standard Inserts

Standard inserts offer cost-effective production due to mass manufacturing and streamlined inventory management. Their consistent dimensions ensure compatibility across a wide range of tools and applications, reducing setup time and minimizing errors. Availability in various grades and coatings allows for flexibility in meeting different machining requirements while maintaining reliable performance.

Applications Best Suited for Custom Inserts

Custom inserts are ideal for applications requiring precise fit, enhanced protection, and unique packaging needs, such as high-value electronics, medical instruments, and luxury goods. These inserts optimize space and ensure product stability during shipping, reducing damage and improving customer experience. Your choice of custom inserts will boost brand perception and product safety compared to standard inserts designed for generic use.

When to Choose Standard Inserts

Standard inserts are ideal when you need reliable, cost-effective solutions for common machining tasks with predictable material properties and geometry. They offer consistent performance and easy availability, making them suitable for high-volume production runs where tool change time must be minimized. You can select standard inserts when the application does not require specialized shapes, coatings, or materials tailored to unique cutting conditions.

Cost Comparison: Custom vs Standard Inserts

Custom inserts typically entail higher upfront costs due to tailored design, specialized materials, and precise manufacturing processes, while standard inserts benefit from economies of scale, making them more cost-effective for general applications. Your choice depends on the specific requirements of your project; custom inserts provide exact fit and functionality, which can reduce long-term expenses related to inefficiency or damage, whereas standard inserts offer affordable solutions with faster availability. Evaluating the total cost of ownership, including installation and potential replacement, helps determine the best financial option for your needs.

Performance and Durability Factors

Custom inserts are tailored to specific applications, offering enhanced performance by optimizing geometry and material composition for your unique operating conditions. Standard inserts provide reliable durability but may lack the precision fit and material enhancements that reduce wear and extend tool life in demanding environments. Performance differences arise from custom inserts' ability to minimize cutting forces and heat buildup, directly improving efficiency and longevity.

Customization Options and Flexibility

Custom inserts offer unparalleled customization options, allowing precise dimensions, materials, and features tailored to specific applications for optimal performance. Unlike standard inserts, which come with fixed specifications and limited adaptability, custom inserts provide flexibility to meet unique operational demands and enhance compatibility with specialized equipment. This flexibility in design and material selection ensures improved efficiency, durability, and function across diverse industrial and manufacturing settings.

Which Insert Type is Right for Your Needs?

Choosing between custom inserts and standard inserts depends on your specific project requirements and budget. Custom inserts offer precise fit and protection tailored to unique product dimensions, ideal for fragile or high-value items. Standard inserts provide cost-effective, versatile solutions suitable for common packaging needs and large production runs.

Custom insert vs standard insert Infographic

libmatt.com

libmatt.com