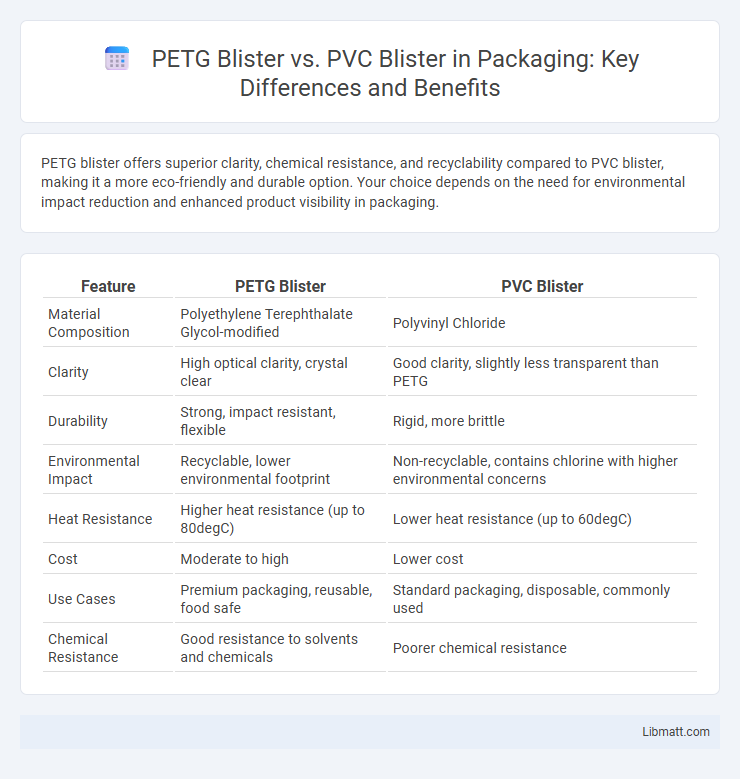

PETG blister offers superior clarity, chemical resistance, and recyclability compared to PVC blister, making it a more eco-friendly and durable option. Your choice depends on the need for environmental impact reduction and enhanced product visibility in packaging.

Table of Comparison

| Feature | PETG Blister | PVC Blister |

|---|---|---|

| Material Composition | Polyethylene Terephthalate Glycol-modified | Polyvinyl Chloride |

| Clarity | High optical clarity, crystal clear | Good clarity, slightly less transparent than PETG |

| Durability | Strong, impact resistant, flexible | Rigid, more brittle |

| Environmental Impact | Recyclable, lower environmental footprint | Non-recyclable, contains chlorine with higher environmental concerns |

| Heat Resistance | Higher heat resistance (up to 80degC) | Lower heat resistance (up to 60degC) |

| Cost | Moderate to high | Lower cost |

| Use Cases | Premium packaging, reusable, food safe | Standard packaging, disposable, commonly used |

| Chemical Resistance | Good resistance to solvents and chemicals | Poorer chemical resistance |

Introduction to PETG and PVC Blister Packaging

PETG blister packaging, made from polyethylene terephthalate glycol, offers high clarity, impact resistance, and superior chemical resistance compared to traditional PVC blister packaging. PVC blister, derived from polyvinyl chloride, is widely used due to its cost-effectiveness and good durability but tends to be less transparent and more brittle over time. PETG blisters provide enhanced product visibility and environmental benefits, while PVC blisters remain popular in industries prioritizing budget-friendly packaging solutions.

Material Composition: PETG vs PVC

PETG blister packaging is made from polyethylene terephthalate glycol-modified, a thermoplastic polyester known for its clarity, chemical resistance, and toughness. PVC blister packaging consists of polyvinyl chloride, a widely used plastic that offers good rigidity but can release harmful chlorine-based substances during disposal. PETG's non-toxic composition and recyclability make it a more environmentally friendly option compared to PVC, which often requires additives like plasticizers to enhance flexibility but can pose health and environmental concerns.

Environmental Impact and Sustainability

PETG blister packaging significantly reduces environmental impact due to its recyclability and lower carbon footprint compared to PVC blister packs. PVC blisters release harmful dioxins during production and disposal, contributing to environmental pollution, whereas PETG is more eco-friendly and easier to recycle. Choosing PETG for your packaging supports sustainability efforts by minimizing hazardous waste and promoting a circular economy.

Clarity and Visual Appeal Comparison

PETG blister packaging offers superior clarity and a glossy finish, enhancing the visual appeal of your products by providing a sharp, transparent view that highlights details more vividly than PVC blister. PVC blister often appears slightly hazy or matte, which can diminish the overall presentation quality and reduce consumer appeal. Choosing PETG ensures a brighter, more attractive display that can effectively boost product visibility and marketability.

Durability and Protection Capabilities

PETG blister packaging offers superior durability compared to PVC blister packs due to its higher impact resistance and better resistance to cracking under stress. PETG provides enhanced protection against moisture and chemical exposure, ensuring product integrity over extended shelf life. Its greater clarity and toughness make PETG an ideal choice for safeguarding sensitive products while maintaining visual appeal.

Manufacturing and Processing Differences

PETG blister packaging offers superior thermoforming capabilities compared to PVC blister, allowing for more precise, detailed shapes with thinner material usage. PETG manufacturing involves lower processing temperatures and emits fewer harmful chemicals, enhancing workplace safety and environmental compliance. Your choice can impact production efficiency and sustainability due to PETG's recyclability versus PVC's more complex disposal requirements.

Cost Analysis: PETG vs PVC Blisters

PETG blisters generally incur higher material costs compared to PVC blisters due to their superior clarity and impact resistance. However, PETG offers long-term savings by providing better durability and recyclability, which can reduce replacement and disposal expenses. Your choice between PETG and PVC blisters should weigh initial cost differences against environmental benefits and product protection needs.

Applications and Industry Preferences

PETG blister packaging is preferred in the medical and electronics industries due to its superior clarity, chemical resistance, and recyclability, making it ideal for sensitive products. PVC blister packaging remains popular in retail and consumer goods because of its cost-effectiveness and ease of thermoforming, despite environmental concerns. Your choice between PETG and PVC should consider industry-specific requirements for durability, transparency, and environmental impact.

Regulatory and Safety Compliance

PETG blister packaging offers superior regulatory and safety compliance compared to PVC blister due to its non-toxic, BPA-free composition and recyclability, aligning with FDA and EU pharmaceutical packaging standards. PVC blister packaging can release harmful chlorine-based compounds during manufacture and disposal, posing environmental and health risks that often conflict with stricter regulatory requirements. Choosing PETG ensures your products meet higher safety protocols, minimizing potential regulatory challenges and enhancing consumer trust.

Choosing the Right Blister Packaging for Your Product

PETG blister packaging offers superior clarity, impact resistance, and environmental benefits compared to traditional PVC blister packs, making it ideal for products requiring high visibility and durability. PVC blister packaging remains cost-effective and widely used but can release harmful chemicals during production and disposal, which may concern sustainability-focused brands. Evaluating your product's protection needs, shelf appeal, and ecological impact will help you choose the right blister material for optimal performance and consumer appeal.

PETG blister vs PVC blister Infographic

libmatt.com

libmatt.com