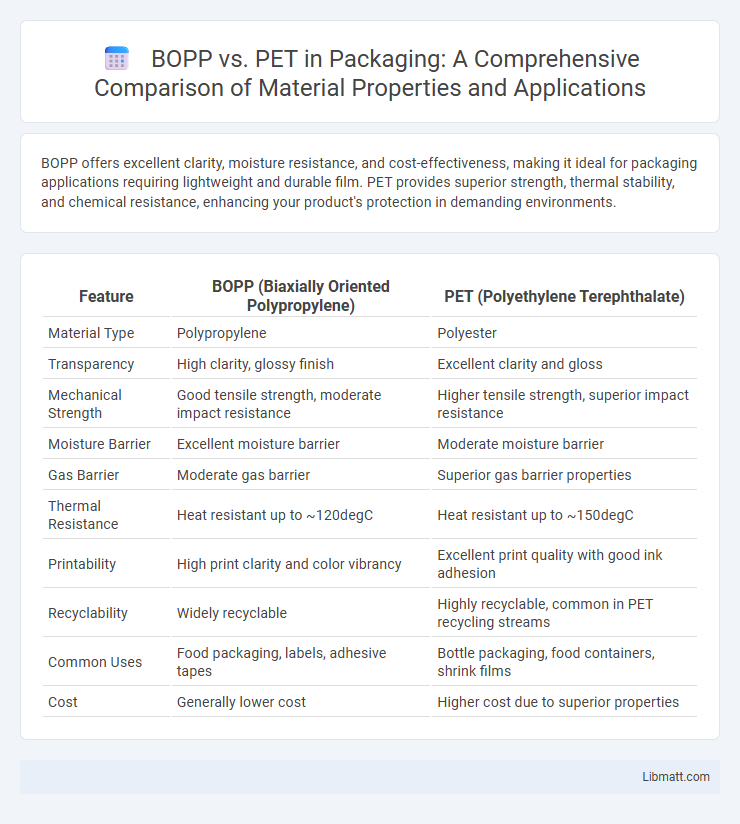

BOPP offers excellent clarity, moisture resistance, and cost-effectiveness, making it ideal for packaging applications requiring lightweight and durable film. PET provides superior strength, thermal stability, and chemical resistance, enhancing your product's protection in demanding environments.

Table of Comparison

| Feature | BOPP (Biaxially Oriented Polypropylene) | PET (Polyethylene Terephthalate) |

|---|---|---|

| Material Type | Polypropylene | Polyester |

| Transparency | High clarity, glossy finish | Excellent clarity and gloss |

| Mechanical Strength | Good tensile strength, moderate impact resistance | Higher tensile strength, superior impact resistance |

| Moisture Barrier | Excellent moisture barrier | Moderate moisture barrier |

| Gas Barrier | Moderate gas barrier | Superior gas barrier properties |

| Thermal Resistance | Heat resistant up to ~120degC | Heat resistant up to ~150degC |

| Printability | High print clarity and color vibrancy | Excellent print quality with good ink adhesion |

| Recyclability | Widely recyclable | Highly recyclable, common in PET recycling streams |

| Common Uses | Food packaging, labels, adhesive tapes | Bottle packaging, food containers, shrink films |

| Cost | Generally lower cost | Higher cost due to superior properties |

Introduction to BOPP and PET Films

BOPP (Biaxially Oriented Polypropylene) and PET (Polyethylene Terephthalate) films are widely used in packaging and labeling due to their unique physical properties. BOPP film is known for its high clarity, toughness, and moisture resistance, making it ideal for food packaging and labels. PET film offers superior strength, chemical resistance, and dimensional stability, which suits applications requiring durability and barrier protection.

Chemical Composition and Properties

BOPP (Biaxially Oriented Polypropylene) is a polymer made from polypropylene, characterized by high tensile strength, clarity, and resistance to moisture and chemicals, making it ideal for packaging applications. PET (Polyethylene Terephthalate) is a polyester resin with excellent gas barrier properties, superior thermal stability, and strong resistance to impact and chemicals, commonly used in bottles and food containers. The chemical structure of BOPP provides greater flexibility and lower density, while PET offers enhanced durability and recyclability due to its aromatic polyester chains.

Key Differences Between BOPP and PET

BOPP (Biaxially Oriented Polypropylene) offers excellent clarity, moisture resistance, and cost-effectiveness, making it ideal for food packaging and labels. PET (Polyethylene Terephthalate) stands out for its superior strength, thermal stability, and recyclability, commonly used in bottles and durable packaging. Your choice depends on whether clarity and flexibility or strength and heat resistance are prioritized in the application.

Strength and Durability Comparison

BOPP (Biaxially Oriented Polypropylene) offers good tensile strength and excellent resistance to moisture, making it ideal for flexible packaging applications where durability is essential. PET (Polyethylene Terephthalate) exhibits superior mechanical strength, impact resistance, and thermal stability, allowing it to withstand higher stress and temperature variations without deformation. When choosing between BOPP and PET, your decision should consider PET's enhanced toughness and longevity for heavy-duty uses versus BOPP's lightweight and moisture barrier benefits.

Barrier Properties: Moisture and Gas Protection

BOPP (Biaxially Oriented Polypropylene) offers moderate moisture barrier properties but lower gas barrier performance compared to PET (Polyethylene Terephthalate), which excels in both moisture and gas protection due to its dense molecular structure. Your choice between BOPP and PET films should consider the specific barrier requirements for moisture vapor transmission rate (MVTR) and oxygen transmission rate (OTR) to ensure product preservation. PET's superior barrier properties make it ideal for packaging sensitive food and pharmaceuticals where extended shelf life is critical.

Printability and Surface Characteristics

BOPP (Biaxially Oriented Polypropylene) offers excellent printability due to its smooth, non-porous surface, enabling high-quality, vibrant graphics with excellent ink adhesion. PET (Polyethylene Terephthalate) features superior surface characteristics with higher dimensional stability and chemical resistance, allowing for sharp, detailed printing and enhanced durability in demanding applications. Both materials excel in print performance, but PET's surface allows for more precise and resilient printing on complex designs and varied substrates.

Application Areas of BOPP vs PET

BOPP (Biaxially Oriented Polypropylene) is widely used in packaging applications such as food wrappers, labels, and tapes due to its excellent moisture resistance, clarity, and printability. PET (Polyethylene Terephthalate) is favored in applications requiring higher barrier properties and durability, including beverage bottles, food containers, and synthetic fibers. While BOPP excels in flexible packaging and labeling, PET dominates in rigid packaging and applications demanding superior strength and thermal stability.

Environmental Impact and Recyclability

BOPP (biaxially oriented polypropylene) offers lower carbon emissions during production compared to PET (polyethylene terephthalate), making it a more environmentally friendly option in terms of energy consumption. PET is widely recycled due to established collection and processing infrastructure, while BOPP recycling faces challenges from its lower market demand and fewer facilities accepting it. Choosing materials that align with your sustainability goals requires considering the differences in recyclability rates and environmental footprints of BOPP and PET.

Cost Factors and Market Availability

BOPP (Biaxially Oriented Polypropylene) generally offers lower production costs due to cheaper raw materials and simpler manufacturing processes compared to PET (Polyethylene Terephthalate). PET provides higher market availability for applications requiring superior strength, clarity, and temperature resistance, making it preferred for premium packaging. You should consider BOPP for budget-sensitive projects and PET when durability and performance are critical.

Choosing the Right Film: BOPP or PET?

Choosing between BOPP and PET films depends on your specific packaging needs such as clarity, strength, and moisture resistance. BOPP (Biaxially Oriented Polypropylene) offers excellent printability and moisture barrier properties, making it ideal for snack packaging and labels. PET (Polyethylene Terephthalate) provides superior tensile strength, chemical resistance, and clarity, suited for high-end packaging applications requiring durability and visual appeal.

BOPP vs PET Infographic

libmatt.com

libmatt.com