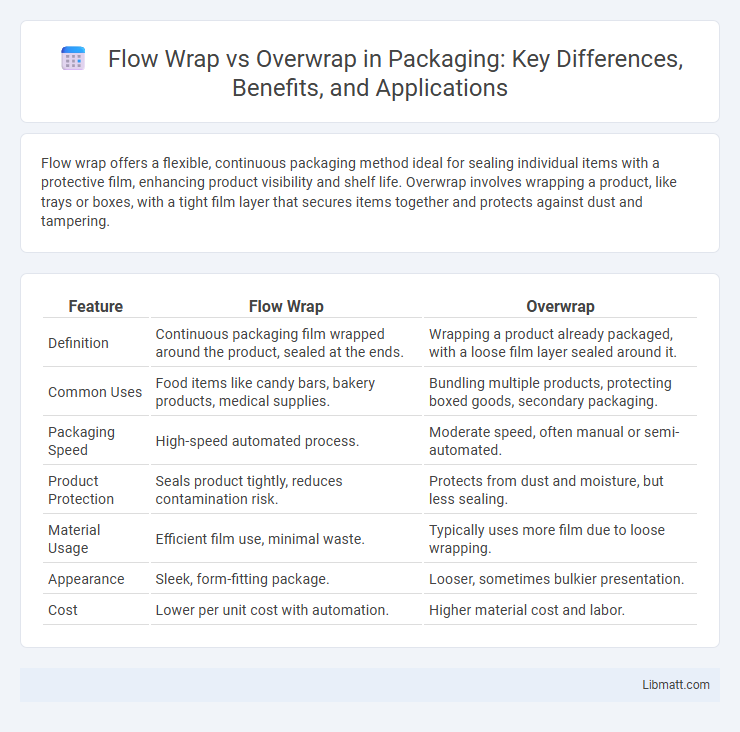

Flow wrap offers a flexible, continuous packaging method ideal for sealing individual items with a protective film, enhancing product visibility and shelf life. Overwrap involves wrapping a product, like trays or boxes, with a tight film layer that secures items together and protects against dust and tampering.

Table of Comparison

| Feature | Flow Wrap | Overwrap |

|---|---|---|

| Definition | Continuous packaging film wrapped around the product, sealed at the ends. | Wrapping a product already packaged, with a loose film layer sealed around it. |

| Common Uses | Food items like candy bars, bakery products, medical supplies. | Bundling multiple products, protecting boxed goods, secondary packaging. |

| Packaging Speed | High-speed automated process. | Moderate speed, often manual or semi-automated. |

| Product Protection | Seals product tightly, reduces contamination risk. | Protects from dust and moisture, but less sealing. |

| Material Usage | Efficient film use, minimal waste. | Typically uses more film due to loose wrapping. |

| Appearance | Sleek, form-fitting package. | Looser, sometimes bulkier presentation. |

| Cost | Lower per unit cost with automation. | Higher material cost and labor. |

Introduction to Flow Wrap and Overwrap

Flow wrap and overwrap are popular packaging methods used in various industries for protecting and presenting products. Flow wrap involves sealing products within a continuous film wrapped tightly around the item, commonly used for snacks and bakery goods. Overwrap, on the other hand, consists of a flat film wrapped around already packaged products, mostly used for items like boxed goods and trays, offering enhanced protection and visibility.

Understanding Flow Wrap Packaging

Flow wrap packaging involves wrapping products in a continuous film sealed at both ends, ideal for individual items like snacks or medical supplies, offering excellent protection and extended shelf life. Overwrap packaging uses a separate film wrapped around a pre-formed product or package, commonly applied to trays or bundled items, enhancing presentation and tamper resistance. Both methods utilize flexible films but differ in application processes and end-use suitability, impacting product preservation and marketing.

Exploring Overwrap Packaging

Overwrap packaging enhances product protection by enclosing items in a tightly sealed film, ideal for maintaining freshness and preventing contamination in food and retail goods. This method offers clarity and durability, making products visually appealing while ensuring structural integrity during transportation and shelving. Comparing overwrap to flow wrap, overwrap typically provides a more rigid barrier and is preferred for multi-unit packaging and items requiring extended shelf life.

How Flow Wrap Works: Process and Materials

Flow wrap packaging uses a continuous flow of film that envelops products in a sealed, protective layer, typically made from polyethylene or polypropylene. The process involves feeding items onto a moving conveyor where the film wraps around, is sealed both longitudinally and transversely, and then cut into individual packages. Your products benefit from this efficient, airtight packaging method that preserves freshness and ensures tamper resistance.

How Overwrap Works: Techniques and Materials

Overwrap involves enclosing products with a transparent film, typically polyethylene or polypropylene, which is heat-sealed or folded around the item to maintain freshness and prevent contamination. Techniques such as shrink wrapping use heat to tighten the film around the product, while cold seal overwrap utilizes adhesives activated by pressure or temperature without heat exposure. Your choice of overwrap materials and methods influences product protection, shelf life, and presentation quality.

Advantages of Flow Wrap Packaging

Flow wrap packaging offers superior product protection by creating a sealed, flexible film barrier that extends shelf life and maintains freshness. Its versatility accommodates various product shapes and sizes, enhancing packaging efficiency while reducing material waste. This method also enables high-speed production, resulting in cost-effective packaging solutions for food, medical, and consumer goods industries.

Benefits of Overwrap Packaging

Overwrap packaging provides superior product visibility, enhancing customer appeal and boosting sales by showcasing your items clearly on the shelf. It offers excellent protection against dust, moisture, and contamination, extending product shelf life and maintaining freshness. This type of packaging also supports tamper-evident seals, ensuring product integrity and consumer safety.

Flow Wrap vs Overwrap: Key Differences

Flow wrap and overwrap differ primarily in packaging technique and product protection. Flow wrap uses continuous film that is sealed around individual items, offering efficient packaging for irregular shapes and maintaining hygiene. Overwrap involves wrapping a separate film around already packaged products, providing an additional layer of protection and improved visual appeal for your retail display.

Choosing the Right Packaging Solution

Choosing the right packaging solution involves understanding the key differences between flow wrap and overwrap methods, as flow wrap offers a continuous, flexible film that tightly seals individual products, enhancing shelf appeal and freshness. Overwrap uses a loose film around a product or group of products, providing protection and tamper evidence while allowing easy display and handling. Your choice depends on product shape, protection needs, and presentation, ensuring optimal packaging performance and customer satisfaction.

Industry Applications and Case Studies

Flow wrap packaging excels in the food industry, providing efficient sealing for items like bakery products, confectionery, and frozen foods, ensuring freshness and extended shelf life. Overwrap packaging is widely used in pharmaceutical and retail sectors, offering enhanced product protection and presentation for items such as blister packs, books, and cosmetics. Your choice between flow wrap and overwrap depends on specific industry requirements and case studies demonstrating packaging performance, cost efficiency, and consumer appeal.

Flow wrap vs overwrap Infographic

libmatt.com

libmatt.com