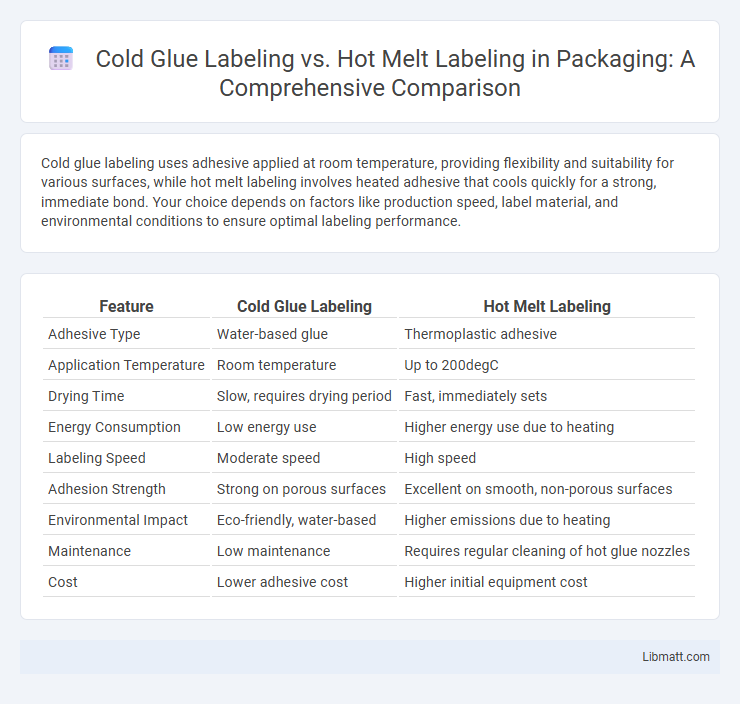

Cold glue labeling uses adhesive applied at room temperature, providing flexibility and suitability for various surfaces, while hot melt labeling involves heated adhesive that cools quickly for a strong, immediate bond. Your choice depends on factors like production speed, label material, and environmental conditions to ensure optimal labeling performance.

Table of Comparison

| Feature | Cold Glue Labeling | Hot Melt Labeling |

|---|---|---|

| Adhesive Type | Water-based glue | Thermoplastic adhesive |

| Application Temperature | Room temperature | Up to 200degC |

| Drying Time | Slow, requires drying period | Fast, immediately sets |

| Energy Consumption | Low energy use | Higher energy use due to heating |

| Labeling Speed | Moderate speed | High speed |

| Adhesion Strength | Strong on porous surfaces | Excellent on smooth, non-porous surfaces |

| Environmental Impact | Eco-friendly, water-based | Higher emissions due to heating |

| Maintenance | Low maintenance | Requires regular cleaning of hot glue nozzles |

| Cost | Lower adhesive cost | Higher initial equipment cost |

Introduction to Labeling Technologies

Cold glue labeling uses a water-based adhesive applied at room temperature, ideal for lightweight containers and flexible packaging, ensuring precise label placement with minimal equipment complexity. Hot melt labeling involves applying a thermoplastic adhesive heated to high temperatures, providing rapid set times and strong bond strength suitable for heavier containers and high-speed production lines. Both technologies optimize label adhesion and durability, selected based on container material, production speed, and environmental considerations.

Overview of Cold Glue Labeling

Cold glue labeling uses water-based adhesives applied at room temperature, offering a cost-effective and environmentally friendly option for packaging. This method provides strong adhesion on porous surfaces such as paper and cardboard, making it ideal for labeling cartons, boxes, and paper-based materials. Your packaging process benefits from reduced energy consumption and easier application with cold glue compared to hot melt labeling.

Overview of Hot Melt Labeling

Hot melt labeling uses thermoplastic adhesives that are applied in a molten state and solidify upon cooling, providing strong and rapid bonding to various substrates. This method is highly efficient for high-speed production lines, offering excellent adhesion to diverse materials such as glass, plastic, and metal. Your packaging process benefits from the durability and quick set-up time inherent in hot melt labeling technology.

Key Differences Between Cold Glue and Hot Melt Labeling

Cold glue labeling uses water-based adhesives that require drying time, making it ideal for paper labels and slower production speeds. Hot melt labeling employs thermoplastic adhesives applied in a molten state, providing instant bonding and better adhesion to plastic or non-porous surfaces. Your choice depends on label material compatibility, production speed, and environmental conditions affecting adhesive performance.

Adhesive Performance and Compatibility

Cold glue labeling offers strong adhesion on smooth, non-porous surfaces, maintaining flexibility and resistance to moisture, making it ideal for paper-based labels. Hot melt labeling provides faster bonding and excellent durability on a wider range of substrates, including plastics and glass, due to its thermoplastic adhesive properties. Your choice depends on the container material and environmental conditions to ensure optimal label performance and longevity.

Speed and Efficiency in Label Application

Cold glue labeling offers moderate speed with consistent adhesion suitable for various surfaces, ideal for labels requiring flexibility and repositioning. Hot melt labeling provides higher speed and instant bond strength, making it efficient for high-volume production lines demanding rapid application and immediate packaging handling. Your choice depends on balancing production speed needs with label durability and substrate compatibility.

Cost Analysis: Cold Glue vs Hot Melt

Cold glue labeling typically incurs lower upfront equipment costs but higher operational expenses due to longer drying times and increased waste. Hot melt labeling demands a larger initial investment in machinery but offers faster application speeds and reduced adhesive usage, leading to cost efficiencies in high-volume production. Your choice depends on balancing initial capital outlay with long-term operational savings.

Label Quality and Aesthetics

Cold glue labeling offers superior label quality with smooth, consistent adhesion that prevents bubbling or wrinkling, resulting in a clean, professional appearance on various packaging surfaces. Hot melt labeling provides robust durability and faster drying times, but may sometimes cause slight label distortion or uneven edges if not applied with precise temperature control. Both methods can achieve high-quality aesthetics; however, cold glue labels generally deliver a more polished, seamless finish especially for high-end packaging applications.

Environmental Impact and Sustainability

Cold glue labeling typically has a lower environmental impact compared to hot melt labeling due to its water-based adhesives, which are easier to recycle and produce fewer volatile organic compounds (VOCs). Hot melt adhesives often contain synthetic polymers that can be less eco-friendly and more challenging to remove during recycling processes. Choosing cold glue labeling can enhance your product's sustainability profile by supporting recyclable packaging and reducing harmful emissions.

Choosing the Right Labeling Solution for Your Production Line

Cold glue labeling offers precise adhesion suitable for delicate surfaces and lower temperature operations, ensuring minimal distortion and residue, ideal for products sensitive to heat. Hot melt labeling provides fast-setting bonds with high durability and moisture resistance, making it optimal for high-speed production lines requiring rapid packaging and robust label adhesion. Selecting the right solution depends on production speed, substrate type, and environmental conditions to maximize efficiency and label quality.

Cold glue labeling vs hot melt labeling Infographic

libmatt.com

libmatt.com