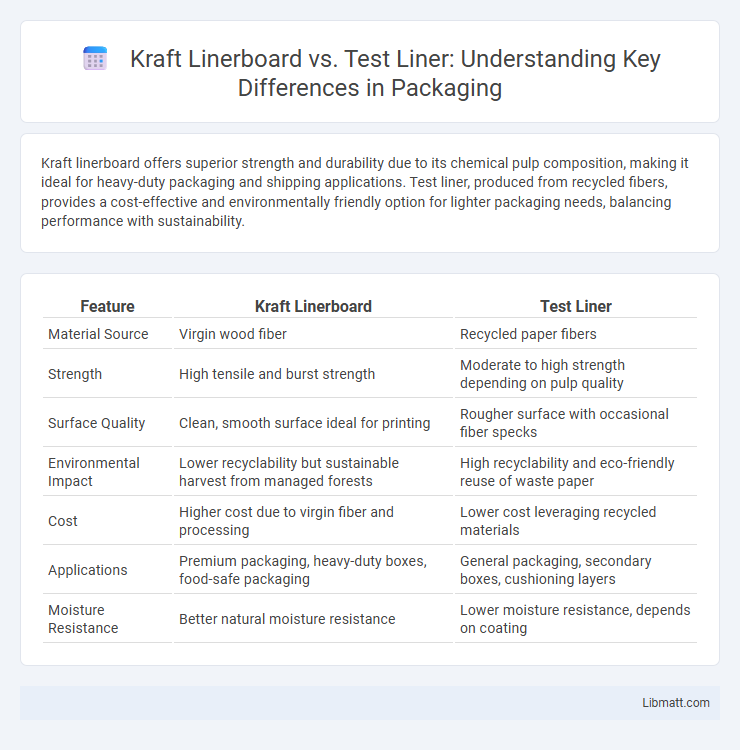

Kraft linerboard offers superior strength and durability due to its chemical pulp composition, making it ideal for heavy-duty packaging and shipping applications. Test liner, produced from recycled fibers, provides a cost-effective and environmentally friendly option for lighter packaging needs, balancing performance with sustainability.

Table of Comparison

| Feature | Kraft Linerboard | Test Liner |

|---|---|---|

| Material Source | Virgin wood fiber | Recycled paper fibers |

| Strength | High tensile and burst strength | Moderate to high strength depending on pulp quality |

| Surface Quality | Clean, smooth surface ideal for printing | Rougher surface with occasional fiber specks |

| Environmental Impact | Lower recyclability but sustainable harvest from managed forests | High recyclability and eco-friendly reuse of waste paper |

| Cost | Higher cost due to virgin fiber and processing | Lower cost leveraging recycled materials |

| Applications | Premium packaging, heavy-duty boxes, food-safe packaging | General packaging, secondary boxes, cushioning layers |

| Moisture Resistance | Better natural moisture resistance | Lower moisture resistance, depends on coating |

Introduction to Kraft Linerboard and Test Liner

Kraft linerboard is a strong, durable paperboard made from virgin wood fibers, primarily used in packaging for its superior strength and resistance. Test liner, on the other hand, is produced mainly from recycled fibers and offers an economical alternative with moderate strength suitable for less demanding packaging applications. Both materials are commonly used in corrugated board manufacturing, with Kraft linerboard preferred for heavy-duty boxes and test liner for lighter, cost-effective packaging solutions.

Composition and Raw Materials

Kraft linerboard is produced primarily from virgin wood fibers using the kraft pulping process, which yields strong, durable fibers ideal for heavy-duty packaging applications. Test liner is generally manufactured from recycled fibers, often incorporating waste paper and recovered pulp, making it less robust but more cost-effective and environmentally friendly. The raw material selection significantly influences the linerboard's strength, durability, and suitability for various packaging needs.

Manufacturing Processes Compared

Kraft linerboard is produced using virgin wood fibers through the kraft pulping process, which involves chemical digestion to remove lignin and impurities, resulting in strong, durable sheets ideal for heavy-duty packaging. Test liner, however, is typically made from recycled fibers collected from recovered paper and cardboard, employing mechanical pulping and deinking processes that emphasize sustainability but yield lower strength. Your choice depends on balancing strength requirements and environmental considerations in packaging and paper production.

Physical and Mechanical Properties

Kraft linerboard boasts superior physical and mechanical properties, including higher tensile strength, tear resistance, and burst strength, making it ideal for heavy-duty packaging applications. Test liner, typically made from recycled fibers, offers moderate strength and stiffness but tends to have lower resistance to punctures and compression compared to kraft linerboard. The higher fiber quality and longer fiber length in kraft linerboard contribute to its enhanced durability and load-bearing capacity.

Performance in Packaging Applications

Kraft linerboard offers superior strength and durability due to its long fibers and chemical pulping process, making it ideal for heavy-duty packaging applications requiring high burst and tear resistance. Test liner, produced from recycled fibers, provides adequate performance for lighter packaging but has lower moisture resistance and tensile strength compared to kraft linerboard. Your choice depends on the required durability and environmental considerations, with kraft linerboard preferred for robust, protective packaging solutions.

Environmental Impact and Sustainability

Kraft linerboard, produced from virgin wood fibers, offers superior durability but involves higher energy consumption and resource use compared to test liner, which is made primarily from recycled fibers and thus promotes circular economy practices. Test liner's reliance on recycled fibers significantly lowers its carbon footprint and reduces waste in landfills, making it a more sustainable packaging choice. However, advancements in kraft linerboard manufacturing are improving energy efficiency and incorporating sustainable forestry practices to mitigate environmental impact.

Cost and Economic Considerations

Kraft linerboard generally incurs higher production costs due to the use of virgin fibers and more intensive pulping processes, resulting in superior strength and durability ideal for high-quality packaging. Test liner, produced mainly from recycled fibers, offers a cost-effective alternative with lower raw material expenses but may compromise on performance and durability. Companies must balance initial expenditure against product requirements, as kraft linerboard suits premium, heavy-duty applications, while test liner often fits budget-sensitive, less demanding packaging solutions.

Printability and Surface Quality

Kraft linerboard offers superior printability due to its higher brightness, smoother surface, and fewer impurities compared to test liner, resulting in sharper images and vibrant colors for packaging applications. The surface quality of kraft linerboard is enhanced by its long fibers and refined manufacturing process, providing excellent ink absorption and minimal roughness, which supports high-quality printing techniques. Test liner, made from recycled fibers, typically exhibits a rougher texture and lower brightness, limiting its printability and producing duller, less precise printed graphics.

Market Trends and Industry Preferences

Kraft linerboard dominates the market due to its superior strength, durability, and resistance to moisture, making it the preferred choice for packaging heavy-duty products. Test liner, often made from recycled fibers, appeals to cost-sensitive markets seeking sustainability and environmental benefits, driving its growing demand in eco-conscious industries. Your choice between kraft linerboard and test liner should align with product requirements and evolving market trends emphasizing both performance and green packaging solutions.

Choosing the Right Linerboard for Your Needs

Kraft linerboard offers superior strength and durability, making it ideal for heavy-duty packaging and shipping applications where maximum protection is essential. Test liner, made mainly from recycled fibers, provides an eco-friendly and cost-effective solution suited for lighter packaging needs or products with less demanding durability requirements. Understanding your product's weight, shipping conditions, and sustainability goals will help you choose the right linerboard that balances performance and cost effectively.

Kraft linerboard vs test liner Infographic

libmatt.com

libmatt.com