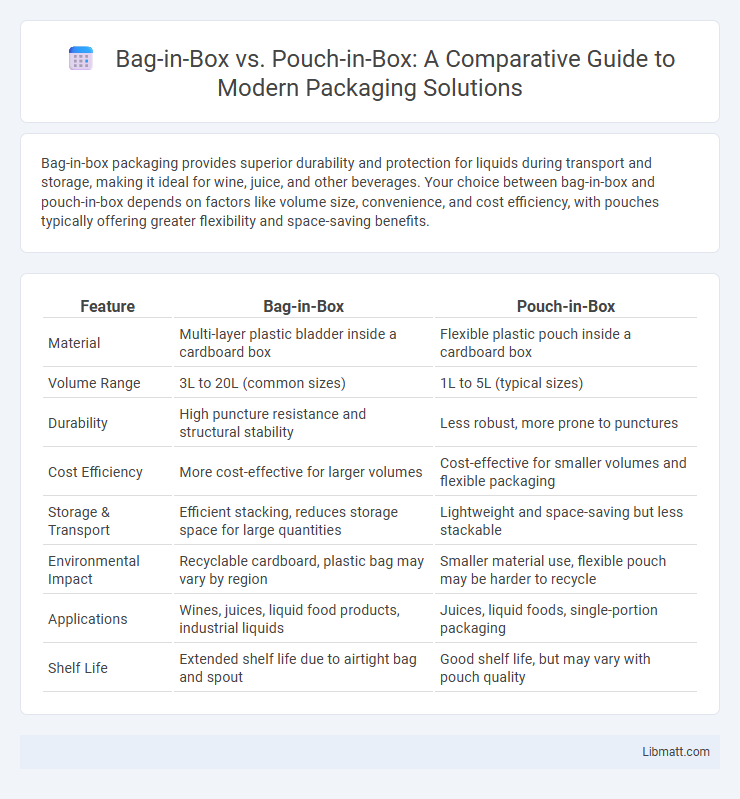

Bag-in-box packaging provides superior durability and protection for liquids during transport and storage, making it ideal for wine, juice, and other beverages. Your choice between bag-in-box and pouch-in-box depends on factors like volume size, convenience, and cost efficiency, with pouches typically offering greater flexibility and space-saving benefits.

Table of Comparison

| Feature | Bag-in-Box | Pouch-in-Box |

|---|---|---|

| Material | Multi-layer plastic bladder inside a cardboard box | Flexible plastic pouch inside a cardboard box |

| Volume Range | 3L to 20L (common sizes) | 1L to 5L (typical sizes) |

| Durability | High puncture resistance and structural stability | Less robust, more prone to punctures |

| Cost Efficiency | More cost-effective for larger volumes | Cost-effective for smaller volumes and flexible packaging |

| Storage & Transport | Efficient stacking, reduces storage space for large quantities | Lightweight and space-saving but less stackable |

| Environmental Impact | Recyclable cardboard, plastic bag may vary by region | Smaller material use, flexible pouch may be harder to recycle |

| Applications | Wines, juices, liquid food products, industrial liquids | Juices, liquid foods, single-portion packaging |

| Shelf Life | Extended shelf life due to airtight bag and spout | Good shelf life, but may vary with pouch quality |

Overview of Bag-in-Box and Pouch-in-Box Packaging

Bag-in-box packaging features a flexible plastic bag housed within a rigid outer box, ideal for large-volume liquid storage and dispensing. Pouch-in-box packaging uses a flexible pouch inside a cardboard box, offering a lightweight, space-saving solution with enhanced portability. Both systems provide extended product shelf life and efficient dispensing, with your choice depending on volume requirements and handling preferences.

Key Differences Between Bag-in-Box and Pouch-in-Box

Bag-in-box packaging features a flexible bag inside a rigid outer box, designed for large volume storage and easy dispensing, whereas pouch-in-box uses a flexible pouch inside a box, offering a lighter and more compact solution for smaller quantities. Bag-in-box systems provide superior durability and longer shelf life with reliable puncture resistance, while pouch-in-box emphasizes portability and reduced material usage. Your choice depends on the specific application, volume requirements, and prioritization of sustainability and convenience.

Material Composition and Sustainability Factors

Bag-in-box packaging typically features a plastic bladder, often made from multilayer polyethylene or metallized films, encased in a cardboard outer box, offering excellent barrier properties and recyclability of the cardboard component. Pouch-in-box uses flexible pouches composed of laminated plastic films with layers like polyethylene and aluminum foil, combined with a cardboard box, which reduces plastic usage but complicates recycling due to multilayer films. Sustainability factors favor bag-in-box systems for easier separation of materials and higher recycling rates, while pouch-in-box designs prioritize material reduction and lighter weight, lowering transportation emissions but presenting challenges in recycling multilayer pouches.

Product Applications for Each Packaging Solution

Bag-in-box packaging suits large-volume liquids such as wine, juice, and bulk condiments, offering extended shelf life and easy dispensing. Pouch-in-box packaging is ideal for smaller quantities, including single-serve beverages, liquid detergents, and sauces, providing lightweight convenience and space efficiency. Each solution targets specific market needs with bag-in-box excelling in high-capacity storage and pouch-in-box optimizing portability and retail shelf appeal.

Cost Comparison: Bag-in-Box vs Pouch-in-Box

Bag-in-box packaging generally offers lower overall costs due to larger volume capacity and reduced material usage, making it ideal for bulk liquids. Pouch-in-box solutions tend to have higher per-unit costs but provide advantages in portability and storage efficiency. Your choice between bag-in-box and pouch-in-box should consider both initial packaging expenses and long-term handling efficiencies.

Storage and Transportation Efficiency

Bag-in-box packaging offers superior storage and transportation efficiency due to its rectangular shape, which maximizes space utilization in pallets and shipping containers. Pouch-in-box designs, while lighter and more flexible, often occupy irregular space that can lead to less efficient stacking and higher transportation costs. Both options reduce product exposure to air, but bag-in-box systems typically deliver better volume-to-weight ratios that optimize logistics and reduce overall carbon footprint.

Shelf Life and Product Protection

Bag-in-box packaging offers superior shelf life by providing an airtight seal that prevents oxidation and contamination, preserving product freshness for weeks after opening. Pouch-in-box designs are more flexible but may have shorter shelf life due to increased permeability and less rigid protection against external damage. Your choice between these packaging types should consider the required product protection and desired shelf life to optimize quality and customer satisfaction.

Consumer Convenience and Dispensing Mechanisms

Bag-in-box packaging offers superior consumer convenience with its built-in tap dispensing mechanism that allows for easy, controlled pouring without lifting the entire container. Pouch-in-box designs, while lightweight and flexible, often require manual handling and may not have integrated spouts, which can lead to spillage or less precise dispensing. Your choice between the two should consider ease of use and the dispensing efficiency needed for your product.

Environmental Impact and Recycling Options

Bag-in-box packaging offers enhanced environmental benefits compared to pouch-in-box due to its larger capacity, which reduces overall material usage and transportation emissions. Recycling options for bag-in-box are more developed, with separate components like cardboard and plastic bags accepted in many municipal recycling programs, whereas pouch-in-box packaging often combines materials in a way that complicates recycling efforts. The improved sustainability of bag-in-box systems supports waste reduction and resource efficiency, making it a preferred choice for eco-conscious consumers and businesses.

Choosing the Right Packaging: Factors to Consider

Choosing the right packaging between bag-in-box and pouch-in-box depends on factors like product volume, shelf life, and transportation needs. Bag-in-box offers sturdy protection and longer preservation for bulk liquids, while pouch-in-box provides lightweight, flexible packaging ideal for smaller quantities and eco-friendly shipping. Your decision should consider cost-effectiveness, environmental impact, and how the packaging supports your brand's usability requirements.

Bag-in-box vs pouch-in-box Infographic

libmatt.com

libmatt.com