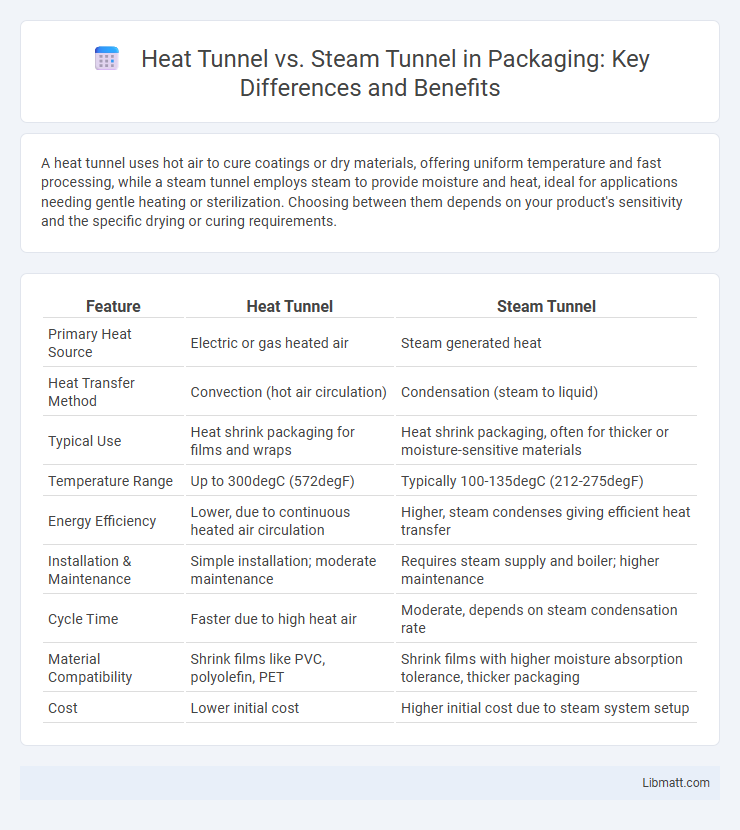

A heat tunnel uses hot air to cure coatings or dry materials, offering uniform temperature and fast processing, while a steam tunnel employs steam to provide moisture and heat, ideal for applications needing gentle heating or sterilization. Choosing between them depends on your product's sensitivity and the specific drying or curing requirements.

Table of Comparison

| Feature | Heat Tunnel | Steam Tunnel |

|---|---|---|

| Primary Heat Source | Electric or gas heated air | Steam generated heat |

| Heat Transfer Method | Convection (hot air circulation) | Condensation (steam to liquid) |

| Typical Use | Heat shrink packaging for films and wraps | Heat shrink packaging, often for thicker or moisture-sensitive materials |

| Temperature Range | Up to 300degC (572degF) | Typically 100-135degC (212-275degF) |

| Energy Efficiency | Lower, due to continuous heated air circulation | Higher, steam condenses giving efficient heat transfer |

| Installation & Maintenance | Simple installation; moderate maintenance | Requires steam supply and boiler; higher maintenance |

| Cycle Time | Faster due to high heat air | Moderate, depends on steam condensation rate |

| Material Compatibility | Shrink films like PVC, polyolefin, PET | Shrink films with higher moisture absorption tolerance, thicker packaging |

| Cost | Lower initial cost | Higher initial cost due to steam system setup |

Introduction to Heat Tunnels and Steam Tunnels

Heat tunnels use elevated air temperatures to cure or dry coatings, adhesives, and materials, allowing for efficient thermal processing without moisture. Steam tunnels employ saturated steam to create a humid, high-temperature environment that penetrates fabrics or products for rapid heat transfer and curing. Both technologies are integral in industries such as textiles, automotive, and electronics, offering tailored solutions for material treatment and finishing.

How Heat Tunnels Work

Heat tunnels operate by circulating hot air around products to evenly dry, cure, or heat-treat materials such as packaging, coatings, or adhesives. The controlled temperature and airflow maximize energy efficiency while preventing damage to sensitive components. Unlike steam tunnels that rely on steam condensation for heat transfer, heat tunnels use convective heat, allowing precise temperature regulation and faster processing times.

How Steam Tunnels Operate

Steam tunnels operate by channeling steam at controlled pressure and temperature through enclosed passageways, effectively heating garments or materials uniformly. The steam penetrates fabrics, relaxing fibers and removing wrinkles without physical contact, making the process ideal for delicate textiles. This method ensures rapid, consistent drying and pressing, enhancing production efficiency in industrial laundry and garment finishing operations.

Key Differences Between Heat and Steam Tunnels

Heat tunnels use hot air circulation to dry and cure coatings or adhesives, providing controlled temperature ranges typically between 60degC to 150degC. Steam tunnels employ saturated steam at higher temperatures, often above 100degC, to accelerate processes like sterilization and fabric finishing by utilizing moisture and heat simultaneously. The key differences lie in their heat transfer methods, temperature settings, and applications, with heat tunnels favoring dry heat and steam tunnels relying on moist heat for efficient thermal treatment.

Efficiency Comparison: Heat Tunnel vs Steam Tunnel

Heat tunnels offer higher energy efficiency by using infrared or convection heating, which quickly supplies consistent heat with minimal energy loss, making them ideal for continuous production lines. Steam tunnels rely on saturated steam that provides uniform, moist heat, effective for curing and shrinking applications but often consuming more energy due to steam generation and condensation cycles. Overall, heat tunnels typically achieve faster cycle times and reduced operational costs compared to steam tunnels, enhancing throughput efficiency in industrial processes.

Application Suitability for Product Types

Heat tunnels are ideal for shrink wrapping bulky or heat-sensitive products such as electronics and large containers, providing uniform heat distribution without moisture. Steam tunnels suit packaging of food items, textiles, and pharmaceuticals where controlled humidity helps achieve a clean, tight seal without damaging delicate materials. Your choice depends on the specific product requirements, with heat tunnels excelling in dry heat applications and steam tunnels preferred for moisture-sensitive packaging.

Cost Analysis: Installation and Maintenance

Heat tunnels generally have lower installation costs compared to steam tunnels due to simpler equipment requirements and less complex piping systems. Maintenance expenses for heat tunnels are often reduced since they lack the high-pressure components and corrosion risks associated with steam systems. For your facility, choosing a heat tunnel can lead to significant long-term savings in both installation and upkeep.

Energy Consumption and Environmental Impact

Heat tunnels generally consume less energy compared to steam tunnels due to direct heating mechanisms that reduce heat loss, resulting in lower operational costs and carbon emissions. Steam tunnels, while effective for uniform heat distribution, often require significant water and fuel resources, leading to higher energy consumption and increased environmental impact from greenhouse gas emissions. Optimizing insulation and using renewable energy sources can mitigate these environmental effects in both heat and steam tunnel systems.

Advantages and Disadvantages of Each System

Heat tunnels offer rapid drying and curing, making them ideal for high-speed production, but they may cause uneven heat distribution and potential damage to heat-sensitive materials. Steam tunnels provide uniform moisture and heat application, improving fabric suppleness and reducing wrinkles, yet they require longer processing times and higher energy consumption. Choosing between heat and steam tunnels depends on the material type, production speed, and energy efficiency considerations.

Choosing the Right Tunnel for Your Packaging Needs

Heat tunnels use controlled dry heat to shrink wrap products quickly, ideal for packaging heat-sensitive items or materials with low moisture content. Steam tunnels employ moist heat for uniform shrink wrapping, suited for products requiring gentle, even shrink films without damage. Selecting between heat and steam tunnels depends on product sensitivity, film compatibility, and desired packaging speed to ensure optimal results.

Heat tunnel vs steam tunnel Infographic

libmatt.com

libmatt.com