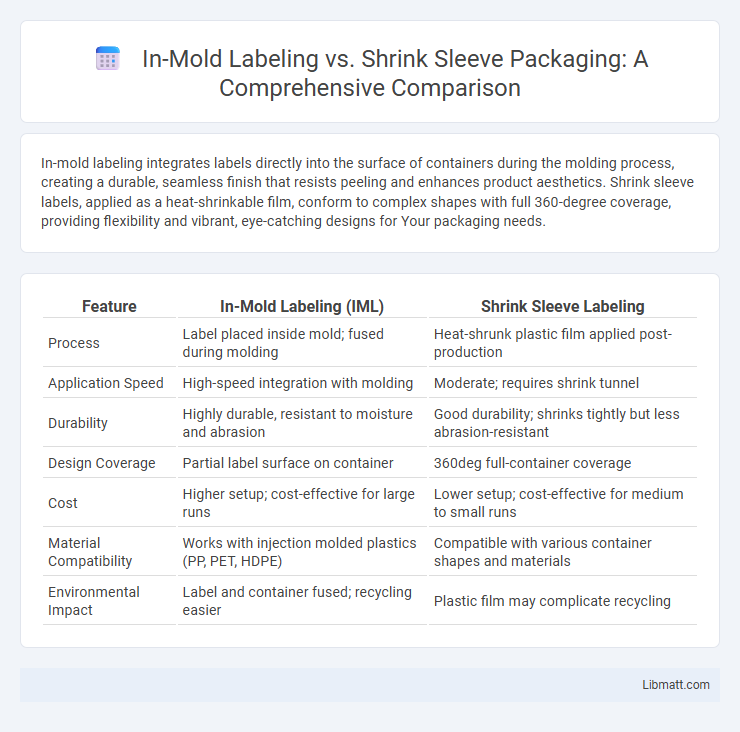

In-mold labeling integrates labels directly into the surface of containers during the molding process, creating a durable, seamless finish that resists peeling and enhances product aesthetics. Shrink sleeve labels, applied as a heat-shrinkable film, conform to complex shapes with full 360-degree coverage, providing flexibility and vibrant, eye-catching designs for Your packaging needs.

Table of Comparison

| Feature | In-Mold Labeling (IML) | Shrink Sleeve Labeling |

|---|---|---|

| Process | Label placed inside mold; fused during molding | Heat-shrunk plastic film applied post-production |

| Application Speed | High-speed integration with molding | Moderate; requires shrink tunnel |

| Durability | Highly durable, resistant to moisture and abrasion | Good durability; shrinks tightly but less abrasion-resistant |

| Design Coverage | Partial label surface on container | 360deg full-container coverage |

| Cost | Higher setup; cost-effective for large runs | Lower setup; cost-effective for medium to small runs |

| Material Compatibility | Works with injection molded plastics (PP, PET, HDPE) | Compatible with various container shapes and materials |

| Environmental Impact | Label and container fused; recycling easier | Plastic film may complicate recycling |

Introduction to In-Mold Labeling and Shrink Sleeve

In-mold labeling (IML) integrates printed labels directly into the container during the molding process, creating a durable, seamless finish ideal for high-quality branding and packaging. Shrink sleeve labels are printed on flexible plastic film that shrinks tightly around the container when heat is applied, offering 360-degree coverage and vibrant, full-color graphics. Choosing between in-mold labeling and shrink sleeve depends on your packaging requirements for durability, design complexity, and production efficiency.

How In-Mold Labeling Works

In-mold labeling (IML) integrates the label directly into the plastic container during the molding process by placing a pre-printed film inside the mold, where it fuses with the molten plastic. This method ensures durable, seamless graphics that are resistant to scratches, moisture, and chemicals, providing a high-quality finish. Your packaging achieves enhanced visual appeal and sustainability through the elimination of secondary labeling steps common in shrink sleeve applications.

How Shrink Sleeve Labeling Works

Shrink sleeve labeling involves printing full-color graphics on a plastic film that is then cut into individual sleeves. Each sleeve is placed over a container and passed through a heat tunnel, causing the sleeve to shrink tightly and conform to the container's shape. This process creates a 360-degree, tamper-evident label that enhances brand visibility and product appeal.

Key Differences Between In-Mold Labeling and Shrink Sleeves

In-mold labeling integrates the label directly into the container during the molding process, resulting in a seamless and durable finish resistant to wear and tear. Shrink sleeves are printed plastic labels that are applied to containers and then heat-shrunk to conform to their shape, offering 360-degree coverage and vibrant, high-quality graphics. Key differences include the permanence of in-mold labels as part of the container structure versus the removable nature of shrink sleeves, as well as the suitability of shrink sleeves for complex container shapes and full-body branding.

Material and Design Flexibility

In-mold labeling (IML) uses durable materials like polypropylene or polyethylene that become an integral part of the container, offering excellent design clarity and resistance to wear. Shrink sleeve labels utilize shrinkable polyester or PVC films, providing 360-degree coverage and complex, vibrant designs that conform to intricate container shapes. Your choice depends on whether you prioritize strong label adhesion with molded integration or highly flexible and visually impactful graphics on irregular surfaces.

Cost Comparison: In-Mold Labeling vs Shrink Sleeve

In-mold labeling (IML) typically offers lower long-term costs due to its integration during the molding process, reducing secondary labeling steps and material waste. Shrink sleeve labeling involves higher initial expenses for sleeves and specialized equipment but provides versatile 360-degree coverage and vibrant graphics. Your choice depends on balancing upfront investment against production volume and desired visual impact.

Durability and Performance

In-mold labeling (IML) offers superior durability due to the label being fused directly into the plastic container during molding, resulting in high resistance to abrasion, moisture, and chemicals. Shrink sleeve labels provide excellent 360-degree coverage and vibrant graphics but can be susceptible to damage from heat and moisture over time. Performance-wise, IML delivers long-lasting integrity ideal for products requiring extended shelf life, while shrink sleeves excel in achieving full-body labeling with flexible design options.

Sustainability and Environmental Impact

In-mold labeling (IML) offers superior sustainability by integrating the label directly into the container during molding, eliminating separate waste streams and enhancing recyclability. Shrink sleeve labels, made from multi-layer plastic films, often complicate recycling due to material contamination and higher energy consumption in production. Choosing IML reduces plastic waste and lowers the carbon footprint, making it a more environmentally responsible packaging solution compared to shrink sleeves.

Applications and Industry Use Cases

In-mold labeling (IML) is widely used in food packaging, household products, and automotive parts due to its durability and seamless integration with plastic containers. Shrink sleeve labeling is preferred for complex container shapes in beverage, personal care, and pharmaceutical industries, offering 360-degree branding and tamper-evident features. Your choice depends on the specific application requirements, such as aesthetic appeal, container shape, and environmental resistance.

Choosing the Right Labeling Technique for Your Product

In-mold labeling integrates the label directly into the container during the molding process, providing excellent durability and a seamless finish ideal for high-quality branding on rigid packaging. Shrink sleeve labels offer full 360-degree coverage and flexibility, conforming to complex shapes and allowing vibrant, eye-catching designs suitable for promotional products. Selecting the right labeling technique depends on factors such as packaging material, desired visual impact, production volume, and cost efficiency, with in-mold labeling suitable for long-lasting applications and shrink sleeves excelling in versatility and aesthetics.

In-mold labeling vs shrink sleeve Infographic

libmatt.com

libmatt.com