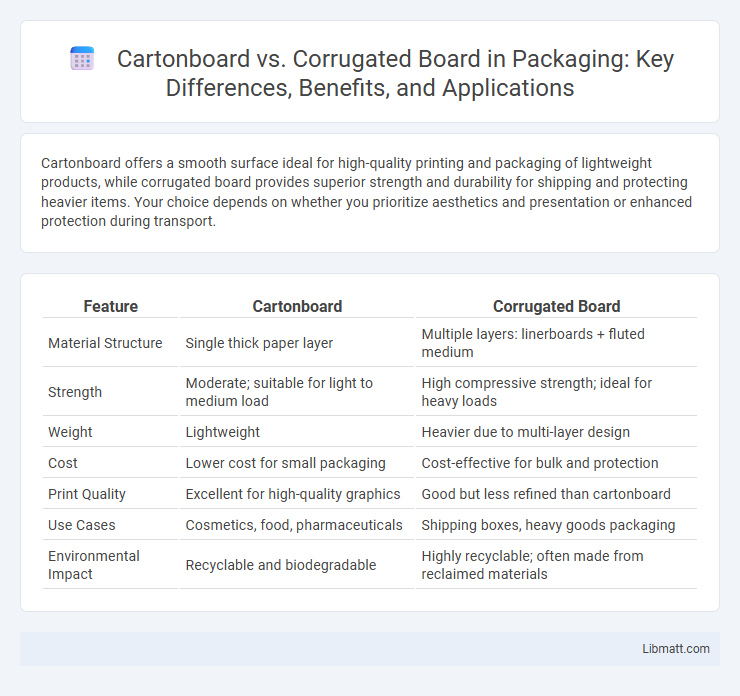

Cartonboard offers a smooth surface ideal for high-quality printing and packaging of lightweight products, while corrugated board provides superior strength and durability for shipping and protecting heavier items. Your choice depends on whether you prioritize aesthetics and presentation or enhanced protection during transport.

Table of Comparison

| Feature | Cartonboard | Corrugated Board |

|---|---|---|

| Material Structure | Single thick paper layer | Multiple layers: linerboards + fluted medium |

| Strength | Moderate; suitable for light to medium load | High compressive strength; ideal for heavy loads |

| Weight | Lightweight | Heavier due to multi-layer design |

| Cost | Lower cost for small packaging | Cost-effective for bulk and protection |

| Print Quality | Excellent for high-quality graphics | Good but less refined than cartonboard |

| Use Cases | Cosmetics, food, pharmaceuticals | Shipping boxes, heavy goods packaging |

| Environmental Impact | Recyclable and biodegradable | Highly recyclable; often made from reclaimed materials |

Introduction to Cartonboard and Corrugated Board

Cartonboard and corrugated board are essential packaging materials designed for different applications, with cartonboard known for its smooth surface and rigidity, ideal for lightweight consumer goods packaging. Corrugated board consists of a fluted corrugated sheet sandwiched between liners, providing superior strength and cushioning, making it suitable for shipping and protection of heavy or fragile items. Both materials are widely used in the packaging industry, with cartonboard favored for retail display and branding, while corrugated board excels in durability and impact resistance during transportation.

What is Cartonboard?

Cartonboard is a thick, paper-based material primarily used for packaging, known for its rigidity and smooth surface that supports high-quality printing. It differs from corrugated board, which consists of a fluted corrugated sheet sandwiched between two liners, offering superior cushioning for heavier or fragile items. You can choose cartonboard for products requiring a premium appearance and lighter protection, especially in retail packaging and luxury goods.

What is Corrugated Board?

Corrugated board consists of a fluted corrugated sheet sandwiched between two flat linerboards, providing exceptional strength and durability for packaging applications. Its structure offers superior cushioning and resistance to impact, making it ideal for shipping and protecting fragile items. Commonly used in boxes, corrugated board is lightweight yet sturdy, ensuring cost-effective and sustainable packaging solutions.

Key Material Differences

Cartonboard, typically made of cellulose fibers, is a solid, stiff material used for packaging lightweight items, while corrugated board consists of a fluted corrugating medium sandwiched between two liners, providing exceptional strength and cushioning. The key material difference lies in weight and structure: cartonboard offers rigidity and printability, ideal for boxes and cartons, whereas corrugated board delivers superior durability and protection, suitable for shipping and heavy goods. Your choice depends on packaging needs, balancing between aesthetic appeal and mechanical strength requirements.

Comparative Strength and Durability

Cartonboard and corrugated board differ significantly in strength and durability, with corrugated board providing superior resistance due to its fluted inner layer that absorbs shocks and withstands heavy loads. Cartonboard, made from a single layer of paper fiber, offers a smooth surface ideal for printing but lacks the rigidity and impact resistance needed for heavy-duty protection. Your choice depends on the packaging requirements, with corrugated board best for shipping fragile or heavy items and cartonboard suited for lightweight, retail packaging.

Printing and Branding Capabilities

Cartonboard offers superior printing and branding capabilities with smooth surfaces that support high-resolution graphics, vibrant colors, and detailed artwork, making it ideal for premium packaging and retail displays. Corrugated board, while durable and protective, typically provides a rougher texture that limits print quality and color vibrancy, often requiring additional labeling or overprinting techniques. For brands emphasizing visual appeal and intricate design, cartonboard presents a more effective solution compared to the more functional and rugged corrugated board.

Sustainability and Environmental Impact

Cartonboard is often favored for sustainability due to its recyclable and biodegradable nature, making it an eco-friendly option for packaging with lower energy consumption during production. Corrugated board, while also recyclable and widely used for its strength and durability, typically requires more raw materials and energy, which can increase its environmental footprint. Your choice between cartonboard and corrugated board should consider the balance between durability needs and environmental impact to support sustainable packaging goals.

Cost Effectiveness and Applications

Cartonboard offers cost-effective advantages for lightweight packaging, retail boxes, and consumer goods due to its lower material and shipping costs compared to corrugated board. Corrugated board provides superior durability and cushioning, making it ideal for heavy-duty shipping, industrial packaging, and protective transport applications despite slightly higher expenses. Choosing between cartonboard and corrugated board depends on balancing budget constraints with the required strength and protection level for the product.

Choosing the Right Board for Packaging Needs

Cartonboard offers a smooth surface ideal for high-quality printing and lightweight packaging, making it suitable for retail boxes and consumer goods. Corrugated board provides superior strength and cushioning with its fluted inner layer, preferred for shipping fragile or heavy items. Selecting the right board depends on balancing presentation requirements, durability, and protection during transit.

Conclusion: Cartonboard vs Corrugated Board

Cartonboard offers a smooth surface ideal for high-quality printing and lightweight packaging, while corrugated board provides superior strength and cushioning for heavier, more fragile items. Your choice depends on the balance between presentation and protection needs, with cartonboard suited for retail displays and corrugated board preferred for shipping and bulk storage. Both materials play essential roles in packaging solutions, optimizing functionality based on specific product requirements.

Cartonboard vs corrugated board Infographic

libmatt.com

libmatt.com