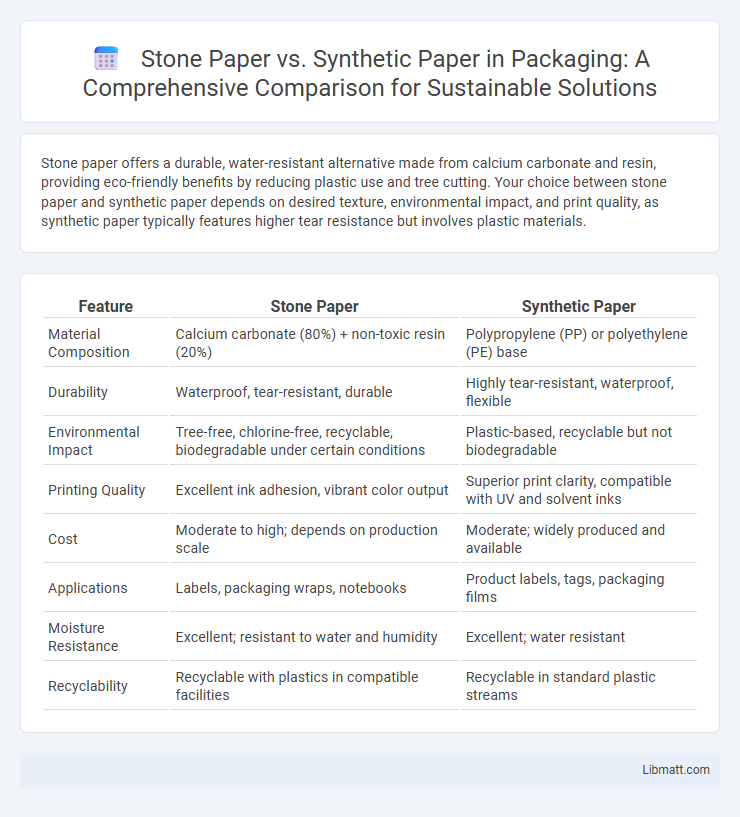

Stone paper offers a durable, water-resistant alternative made from calcium carbonate and resin, providing eco-friendly benefits by reducing plastic use and tree cutting. Your choice between stone paper and synthetic paper depends on desired texture, environmental impact, and print quality, as synthetic paper typically features higher tear resistance but involves plastic materials.

Table of Comparison

| Feature | Stone Paper | Synthetic Paper |

|---|---|---|

| Material Composition | Calcium carbonate (80%) + non-toxic resin (20%) | Polypropylene (PP) or polyethylene (PE) base |

| Durability | Waterproof, tear-resistant, durable | Highly tear-resistant, waterproof, flexible |

| Environmental Impact | Tree-free, chlorine-free, recyclable, biodegradable under certain conditions | Plastic-based, recyclable but not biodegradable |

| Printing Quality | Excellent ink adhesion, vibrant color output | Superior print clarity, compatible with UV and solvent inks |

| Cost | Moderate to high; depends on production scale | Moderate; widely produced and available |

| Applications | Labels, packaging wraps, notebooks | Product labels, tags, packaging films |

| Moisture Resistance | Excellent; resistant to water and humidity | Excellent; water resistant |

| Recyclability | Recyclable with plastics in compatible facilities | Recyclable in standard plastic streams |

Introduction to Stone Paper and Synthetic Paper

Stone paper is an eco-friendly writing material made from calcium carbonate bonded with non-toxic resin, offering waterproof and tear-resistant properties. Synthetic paper, typically produced from polypropylene or polyethylene, mimics traditional paper's texture while providing durability, chemical resistance, and recyclability. Both materials serve as sustainable alternatives to conventional wood-pulp paper, with stone paper emphasizing mineral-based composition and synthetic paper leveraging plastic polymers.

Composition and Manufacturing Processes

Stone paper is composed primarily of calcium carbonate bonded with high-density polyethylene, produced through a dry process that grinds limestone into fine powder and combines it with resin without using water or wood pulp. Synthetic paper typically consists of polypropylene or polyethylene materials created by extruding plastic pellets into sheets that mimic the texture and properties of traditional paper. These differing compositions and manufacturing methods result in stone paper being more environmentally friendly due to its minimal water usage and lack of chemical bleaches, whereas synthetic paper offers superior durability and water resistance.

Environmental Impact Comparison

Stone paper, made from calcium carbonate and resin, offers a lower environmental footprint by eliminating the need for trees and reducing water consumption by up to 60% compared to traditional paper. Synthetic paper, typically polyester-based, has a higher carbon footprint and contributes to microplastic pollution but excels in durability and recyclability in specialized waste streams. Both alternatives avoid chlorine bleaching, reducing toxic chemical discharge into ecosystems, yet stone paper generally ranks better for biodegradability and reduced fossil fuel dependence.

Physical Properties and Durability

Stone paper is made from calcium carbonate bonded with high-density polyethylene, resulting in a smooth, water-resistant surface that resists tearing and is highly durable in humid conditions. Synthetic paper, typically produced from polypropylene or polyethylene, offers excellent tear resistance, waterproof qualities, and chemical durability, making it suitable for outdoor and industrial applications. Both materials outperform traditional wood pulp paper in strength and longevity, with stone paper being more rigid and synthetic paper providing greater flexibility.

Printability and Surface Quality

Stone paper offers excellent printability with smooth, non-porous surfaces that enhance ink adhesion and color vibrancy, making it ideal for high-quality printing. Synthetic paper, made from plastic resins, features exceptional durability and water resistance while maintaining a consistent, matte or glossy finish that supports sharp image reproduction. Both materials provide superior surface quality compared to traditional paper, but stone paper excels in environmental friendliness due to its mineral-based composition.

Water Resistance and Weather Tolerance

Stone paper offers superior water resistance compared to synthetic paper, as its hydrophobic properties prevent moisture absorption and damage. Synthetic paper, while water-resistant, may degrade or peel over extended exposure to harsh weather conditions such as UV rays and freezing temperatures. You can rely on stone paper for durable, weather-tolerant applications requiring long-lasting water resistance.

Applications in Various Industries

Stone paper excels in packaging, printing, and eco-friendly product manufacturing due to its water resistance and durability, making it ideal for labels, bags, and notebooks. Synthetic paper, composed of plastic resins, finds extensive use in outdoor advertising, maps, and technical documents where tear resistance and weather durability are critical. Both materials serve diverse industries, with stone paper favored for sustainability and synthetic paper prized for performance in harsh environments.

Cost Analysis and Market Pricing

Stone paper generally costs more to produce than synthetic paper due to specialized materials like calcium carbonate and resin binders, but its eco-friendly qualities can justify higher market pricing. Synthetic paper, often made from polypropylene, offers lower production costs and competitive pricing, making it a popular choice for large-volume applications. Understanding these cost dynamics helps you evaluate the best option for budget constraints and sustainability goals.

Recycling and End-of-Life Considerations

Stone paper is non-biodegradable but highly recyclable through specialized processes that recover calcium carbonate and HDPE binder, reducing landfill waste. Synthetic paper, often made from polypropylene or polyethylene, is durable and recyclable via standard plastic recycling streams but may contaminate paper recycling due to its plastic content. Both materials require proper sorting to optimize recycling efficiency and minimize environmental impact at the end of their lifecycle.

Which Paper Is Right for Your Needs?

Stone paper offers excellent water resistance, durability, and eco-friendliness due to its mineral-based composition, making it ideal for outdoor or heavy-use applications. Synthetic paper, made from plastic resins, provides superior tear resistance and print quality, which suits professional printing and packaging needs. Your choice depends on whether you prioritize environmental impact and water resistance or print precision and toughness.

Stone paper vs synthetic paper Infographic

libmatt.com

libmatt.com