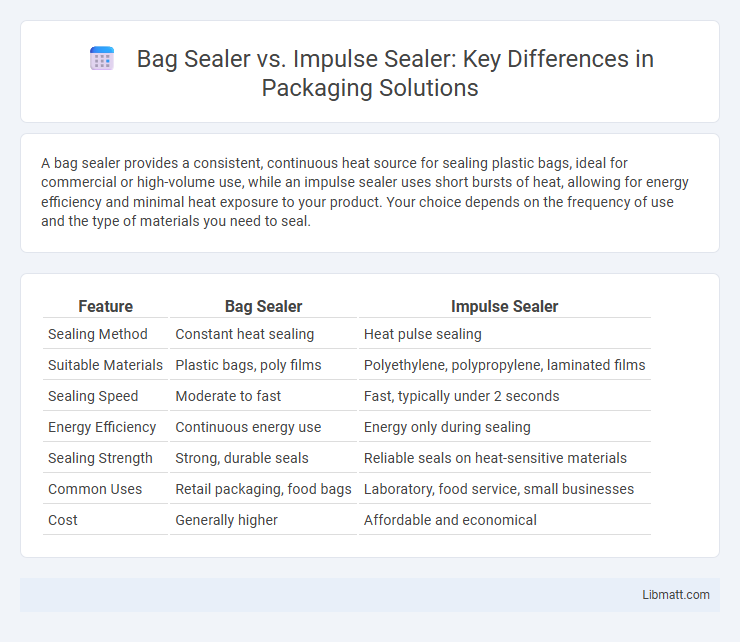

A bag sealer provides a consistent, continuous heat source for sealing plastic bags, ideal for commercial or high-volume use, while an impulse sealer uses short bursts of heat, allowing for energy efficiency and minimal heat exposure to your product. Your choice depends on the frequency of use and the type of materials you need to seal.

Table of Comparison

| Feature | Bag Sealer | Impulse Sealer |

|---|---|---|

| Sealing Method | Constant heat sealing | Heat pulse sealing |

| Suitable Materials | Plastic bags, poly films | Polyethylene, polypropylene, laminated films |

| Sealing Speed | Moderate to fast | Fast, typically under 2 seconds |

| Energy Efficiency | Continuous energy use | Energy only during sealing |

| Sealing Strength | Strong, durable seals | Reliable seals on heat-sensitive materials |

| Common Uses | Retail packaging, food bags | Laboratory, food service, small businesses |

| Cost | Generally higher | Affordable and economical |

Introduction to Bag Sealers and Impulse Sealers

Bag sealers use constant heat to create airtight seals on various packaging materials, ideal for continuous sealing tasks and industrial applications. Impulse sealers employ a brief burst of heat generated by an electric current passing through a heating element, making them efficient for sealing heat-sensitive materials without continuous heating. The key difference lies in temperature control and energy consumption, with impulse sealers providing precise sealing and enhancing safety by avoiding overheating.

What is a Bag Sealer?

A bag sealer is a device designed to close and seal plastic bags by applying heat to the bag's opening, creating an airtight and secure seal that preserves the contents. Unlike impulse sealers, which use a short burst of heat generated by an electric current, traditional bag sealers may provide continuous heat to ensure consistent sealing for various materials such as polyethylene and polypropylene. Bag sealers are essential in packaging industries for food storage, industrial goods, and retail products, enhancing product freshness and preventing contamination.

What is an Impulse Sealer?

An impulse sealer is a device designed to seal plastic bags quickly by applying a brief heat pulse to melt the bag's edges together without continuous heat, making it energy-efficient and safe for various packaging materials. Unlike a traditional bag sealer that may use constant heat, impulse sealers generate heat only when activated, preventing damage to heat-sensitive contents. Your packaging process benefits from precise sealing and reduced energy consumption with an impulse sealer.

Key Features of Bag Sealers

Bag sealers use continuous heat to create airtight seals suitable for thicker materials, while impulse sealers apply heat momentarily, ideal for thinner plastic bags and delicate packaging. Key features include temperature control, seal width, sealing speed, and compatibility with various bag materials. Impulse sealers are energy-efficient and safer due to their brief heating cycles, whereas continuous heat bag sealers offer consistent sealing for larger-scale operations.

Key Features of Impulse Sealers

Impulse sealers utilize a heated wire element that activates only during sealing, providing energy-efficient and precise heat control ideal for sealing various plastic films. Their key features include adjustable sealing time, temperature settings suited for different materials, and the ability to create airtight, durable seals without continuous heating. These sealers excel in safety and versatility, making them suitable for small-scale packaging and lab use compared to continuous heat bag sealers.

Differences Between Bag Sealers and Impulse Sealers

Bag sealers use continuous heat to seal plastic bags, providing consistent temperature control for thicker materials, whereas impulse sealers generate heat only during sealing, preventing heat damage to thin films. Impulse sealers are more energy-efficient and suitable for sealing delicate or heat-sensitive bags, while traditional bag sealers offer faster sealing times suitable for high-volume packaging. The choice depends on bag material, sealing speed requirements, and energy consumption considerations in industrial or commercial packaging operations.

Pros and Cons of Bag Sealers

Bag sealers offer consistent heat sealing, making them ideal for a variety of plastic bags and packaging materials, ensuring airtight storage that preserves product freshness. However, they often require a longer heat-up time and can consume more electricity compared to impulse sealers, which provide instant sealing with less energy usage but may not handle thicker materials as effectively. Your choice depends on the type of bags you frequently seal and the need for efficiency versus versatility in sealing performance.

Pros and Cons of Impulse Sealers

Impulse sealers offer precise, energy-efficient sealing by heating only when activated, making them ideal for sealing various plastic bags without constant power consumption. They provide strong, consistent seals, are cost-effective, and suitable for home or small business use, but their sealing area is limited and may require multiple passes for thicker materials. Your choice depends on the volume of sealing tasks and the types of bags you frequently use.

Choosing the Right Sealer for Your Needs

Selecting the ideal sealer depends on the specific packaging requirements and budget constraints; impulse sealers use heat only when sealing, making them energy-efficient and ideal for low to medium volume sealing of polyethylene or polypropylene bags. Bag sealers, which often rely on constant heat elements, provide continuous sealing and better performance for thicker materials or heavy-duty applications. Evaluating factors such as bag material, sealing speed, and frequency of use will help determine the most efficient and cost-effective sealing equipment for your operation.

Conclusion: Which Sealer is Best for You?

Choosing between a bag sealer and an impulse sealer depends on your specific packaging needs and budget. Bag sealers are ideal for consistent, fast sealing of pre-made bags, providing reliability for high-volume operations. Impulse sealers offer versatility for sealing various plastic types and thicknesses, making them suitable for small businesses or occasional use where precision and adaptability are important.

Bag sealer vs impulse sealer Infographic

libmatt.com

libmatt.com