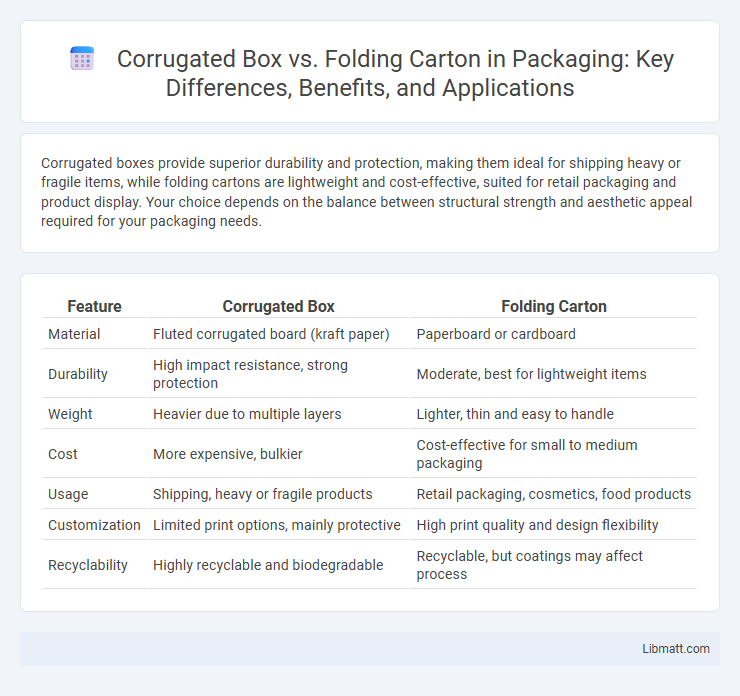

Corrugated boxes provide superior durability and protection, making them ideal for shipping heavy or fragile items, while folding cartons are lightweight and cost-effective, suited for retail packaging and product display. Your choice depends on the balance between structural strength and aesthetic appeal required for your packaging needs.

Table of Comparison

| Feature | Corrugated Box | Folding Carton |

|---|---|---|

| Material | Fluted corrugated board (kraft paper) | Paperboard or cardboard |

| Durability | High impact resistance, strong protection | Moderate, best for lightweight items |

| Weight | Heavier due to multiple layers | Lighter, thin and easy to handle |

| Cost | More expensive, bulkier | Cost-effective for small to medium packaging |

| Usage | Shipping, heavy or fragile products | Retail packaging, cosmetics, food products |

| Customization | Limited print options, mainly protective | High print quality and design flexibility |

| Recyclability | Highly recyclable and biodegradable | Recyclable, but coatings may affect process |

Introduction to Corrugated Boxes and Folding Cartons

Corrugated boxes consist of a fluted corrugated sheet sandwiched between two liners, providing exceptional strength and durability for shipping and heavy-duty packaging. Folding cartons are made from paperboard, designed for lightweight retail packaging with smooth surfaces ideal for high-quality printing and branding. Your choice between the two depends on the need for protection, visual appeal, and the type of products being packaged.

Material Composition: Corrugated vs. Folding

Corrugated boxes are made from multiple layers of kraft paper, including a fluted corrugated sheet sandwiched between two linerboards, providing superior strength and durability for heavy-duty packaging. Folding cartons consist of single-layer paperboard, which is thinner and more lightweight, ideal for retail packaging and easy customization. Your choice between corrugated and folding cartons depends on the required material composition for protection and presentation.

Manufacturing Processes Compared

Corrugated boxes are manufactured by sandwiching a fluted corrugated sheet between two liners using a combination of adhesive and pressure, enabling strong structural integrity ideal for heavier or bulkier items. Folding cartons are created by die-cutting and scoring flat sheets of paperboard, which are then folded and glued to form lightweight, precise packaging often used for retail products. Your choice between these packaging types depends on the manufacturing process compatibility with your product's weight, durability, and presentation needs.

Structural Strength and Durability

Corrugated boxes offer superior structural strength and durability due to their multi-layered construction, making them ideal for heavy-duty shipping and long-term storage. Folding cartons, made from single layers of paperboard, provide less protection but are more suited for lightweight packaging and retail presentation. Your choice should depend on whether strength or aesthetics are the primary priority for your packaging needs.

Weight and Storage Efficiency

Corrugated boxes are significantly heavier due to their thicker multi-layered construction, which provides superior protection but reduces storage efficiency. Folding cartons are lighter and more compact, allowing for better space utilization during storage and transportation. The lighter weight and flat storage capability of folding cartons make them ideal for high-volume, lightweight products requiring efficient shipping.

Customization and Printing Options

Corrugated boxes offer extensive customization options, including variable thickness, flute profiles, and reinforcements, making them ideal for heavy-duty packaging needs. High-quality digital and flexographic printing techniques enable vibrant, detailed branding directly on corrugated surfaces, enhancing product visibility and market appeal. In contrast, folding cartons provide superior print resolution and finish options like UV coating and embossing, allowing for intricate designs and premium aesthetics suited for retail packaging.

Cost Factors and Budget Considerations

Corrugated boxes generally offer lower material and production costs for bulk packaging due to their thicker structure and availability in standard sizes, making them ideal for shipping and heavy-duty applications. Folding cartons, while typically more expensive to produce because of their thinner material and intricate printing options, provide a cost-effective solution for retail packaging where visual appeal influences consumer purchase decisions. Budget considerations should weigh the balance between durability requirements and branding impact, as corrugated boxes minimize transport damage costs, whereas folding cartons enhance shelf presence at a premium price.

Sustainability and Environmental Impact

Corrugated boxes are widely recognized for their sustainability due to their high recyclability and use of renewable materials, making them an eco-friendly choice for packaging. Folding cartons, while also recyclable, typically require more energy-intensive processes and coatings that may affect their environmental impact. The biodegradability and lower carbon footprint of corrugated packaging contribute significantly to reducing overall ecological harm compared to folding cartons.

Typical Applications and Industry Uses

Corrugated boxes are primarily used in shipping, storage, and heavy-duty packaging for industries such as electronics, automotive, and e-commerce due to their durability and cushioning properties. Folding cartons are commonly found in retail packaging, especially for consumer goods like cosmetics, pharmaceuticals, and food products, where visual appeal and easy display are crucial. Both packaging types serve distinct roles, with corrugated boxes excelling in protection and logistics, while folding cartons emphasize branding and product presentation.

Choosing the Right Packaging Solution

Choosing the right packaging solution involves evaluating the durability and purpose of corrugated boxes versus folding cartons. Corrugated boxes offer superior strength and protection for heavy or fragile items during shipping, while folding cartons excel in lightweight, retail-friendly presentation with high-quality printing options. By assessing your product's weight, shipping needs, and display requirements, you can select the packaging that best protects and promotes your brand.

Corrugated box vs folding carton Infographic

libmatt.com

libmatt.com