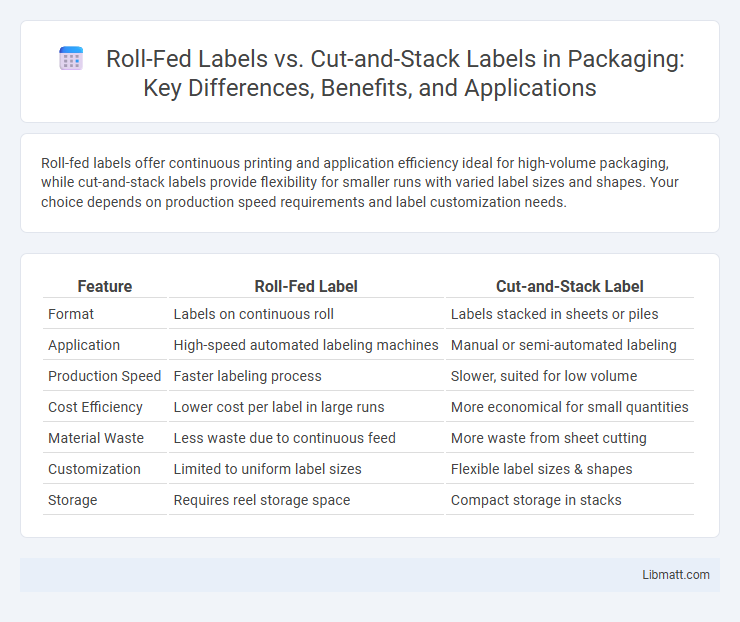

Roll-fed labels offer continuous printing and application efficiency ideal for high-volume packaging, while cut-and-stack labels provide flexibility for smaller runs with varied label sizes and shapes. Your choice depends on production speed requirements and label customization needs.

Table of Comparison

| Feature | Roll-Fed Label | Cut-and-Stack Label |

|---|---|---|

| Format | Labels on continuous roll | Labels stacked in sheets or piles |

| Application | High-speed automated labeling machines | Manual or semi-automated labeling |

| Production Speed | Faster labeling process | Slower, suited for low volume |

| Cost Efficiency | Lower cost per label in large runs | More economical for small quantities |

| Material Waste | Less waste due to continuous feed | More waste from sheet cutting |

| Customization | Limited to uniform label sizes | Flexible label sizes & shapes |

| Storage | Requires reel storage space | Compact storage in stacks |

Introduction to Labeling Methods

Roll-fed labels are continuous labels wound on rolls, designed for high-speed automated labeling systems, offering efficiency and reduced downtime in large-scale production. Cut-and-stack labels come as separate sheets or stacks of pre-cut labels, ideal for smaller runs or manual application, providing flexibility and ease of use. Each method suits distinct operational needs based on production volume, application speed, and equipment compatibility.

What Are Roll-Fed Labels?

Roll-fed labels are continuous labels dispensed from a large roll, offering efficient high-speed application for product packaging and branding. These labels are ideal for automated labeling systems, reducing downtime and waste while accommodating various shapes and sizes. Your packaging process benefits from the consistent quality and faster throughput provided by roll-fed labels compared to cut-and-stack labels.

Understanding Cut-and-Stack Labels

Cut-and-stack labels are individual labels printed on large sheets and then cut into separate pieces, offering high customization and versatility for smaller production runs. These labels are ideal for applications where you need precise shapes or small quantities, making them perfect for custom branding and niche markets. Your choice of cut-and-stack labels ensures maximum design flexibility and easy application on a variety of packaging types.

Key Differences Between Roll-Fed and Cut-and-Stack Labels

Roll-fed labels are continuously printed on large rolls, enabling high-speed application and ideal for automated labeling systems, while cut-and-stack labels are die-cut sheets stacked for manual or semi-automatic use, offering flexibility for short runs and varied label shapes. Roll-fed labels provide greater efficiency in large-scale production with consistent label quality, whereas cut-and-stack labels allow easier customization and lower initial investment for smaller batches. The choice between roll-fed and cut-and-stack labels depends primarily on production volume, application speed, and cost considerations.

Material and Printing Options

Roll-fed labels are typically produced on flexible materials such as polyester, vinyl, and polypropylene, offering versatility for various printing methods including flexography, digital, and thermal transfer. Cut-and-stack labels often use sheets of paper or synthetic materials compatible with laser and inkjet printers, providing options for high-resolution, full-color printing. Both types accommodate custom finishes like gloss, matte, and tamper-evident coatings to enhance durability and appearance.

Application Processes and Machinery

Roll-fed labels are designed for high-speed labeling machines that apply continuous labels directly from large rolls, ideal for automated production lines requiring fast, uninterrupted application. Cut-and-stack labels are separate, pre-cut labels arranged in stacks, compatible with semi-automatic or manual labeling equipment where precise placement is crucial, often used in smaller scale or specialty packaging. Machinery handling roll-fed labels typically features web-driven systems for seamless label dispensing, whereas cut-and-stack systems rely on feeders or pick-and-place mechanisms for individual label application.

Cost Comparison: Roll-Fed vs Cut-and-Stack Labels

Roll-fed labels typically offer a lower cost per unit than cut-and-stack labels due to continuous production efficiency and reduced labor requirements. Cut-and-stack labels incur higher costs because of additional handling, manual placement, and limited automation capabilities. Businesses aiming for large-scale, high-volume labeling often find roll-fed options more cost-effective, while smaller runs might justify cut-and-stack expenses for customization.

Uses and Industries for Each Label Type

Roll-fed labels are widely used in high-speed production environments such as beverage bottling, food packaging, and pharmaceuticals, where continuous labeling on automated lines is essential. Cut-and-stack labels find their primary application in batch operations, ideal for specialty products, cosmetics, and small to medium-sized businesses requiring manual or semi-automated application. Industries like logistics, healthcare, and retail benefit from both types depending on whether speed or customization is prioritized.

Pros and Cons of Roll-Fed Labels

Roll-fed labels offer continuous feed flexibility, ideal for high-volume labeling with faster application speeds and reduced downtime, improving production efficiency. These labels minimize waste due to precise alignment and consistent tension control but require specialized dispensing equipment and can be less cost-effective for short runs or small batches. Roll-fed labels excel in applications needing seamless automation and durability, though setup complexity and initial investment may be higher compared to cut-and-stack labels.

Pros and Cons of Cut-and-Stack Labels

Cut-and-stack labels offer precise size customization and are ideal for short to medium print runs, reducing material waste compared to roll-fed labels. You may face slower application speeds and higher labor costs since these labels require manual or semi-automated application. Their simple packaging and storage make cut-and-stack labels a practical choice for businesses prioritizing flexibility and small batch production.

Roll-fed label vs cut-and-stack label Infographic

libmatt.com

libmatt.com