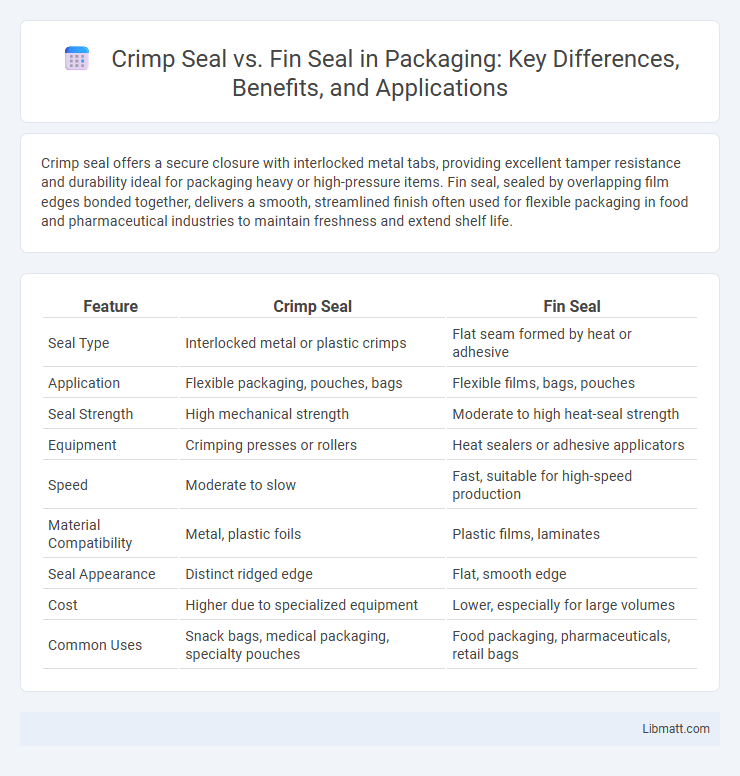

Crimp seal offers a secure closure with interlocked metal tabs, providing excellent tamper resistance and durability ideal for packaging heavy or high-pressure items. Fin seal, sealed by overlapping film edges bonded together, delivers a smooth, streamlined finish often used for flexible packaging in food and pharmaceutical industries to maintain freshness and extend shelf life.

Table of Comparison

| Feature | Crimp Seal | Fin Seal |

|---|---|---|

| Seal Type | Interlocked metal or plastic crimps | Flat seam formed by heat or adhesive |

| Application | Flexible packaging, pouches, bags | Flexible films, bags, pouches |

| Seal Strength | High mechanical strength | Moderate to high heat-seal strength |

| Equipment | Crimping presses or rollers | Heat sealers or adhesive applicators |

| Speed | Moderate to slow | Fast, suitable for high-speed production |

| Material Compatibility | Metal, plastic foils | Plastic films, laminates |

| Seal Appearance | Distinct ridged edge | Flat, smooth edge |

| Cost | Higher due to specialized equipment | Lower, especially for large volumes |

| Common Uses | Snack bags, medical packaging, specialty pouches | Food packaging, pharmaceuticals, retail bags |

Introduction to Packaging Seals

Crimp seal and fin seal are two essential packaging seal types used to secure flexible packaging materials like bags and pouches. Crimp seals create a durable, flat seal by folding and pressing the edges of the packaging material together, offering strong barrier protection against contamination and moisture. Fin seals, commonly used in pillow pouches and form-fill-seal machines, involve overlapping the packaging films and sealing them with heat, providing reliable and efficient packaging for food products and pharmaceuticals.

What is a Crimp Seal?

A crimp seal is a type of sealed closure commonly used in flexible packaging, characterized by a serrated or zigzag pattern created by pressing two layers of film together. This sealing method enhances the package's strength and barrier properties, making it suitable for snacks, coffee, and pharmaceutical products. Crimp seals provide a secure, tamper-evident closure that helps maintain product freshness and prevents contamination.

What is a Fin Seal?

A fin seal is a type of packaging seal created by pressing two layers of flexible film together along a narrow strip, forming a raised ridge that looks like a fin. This sealing method is commonly used in pillow pouches, providing strong, airtight closure ideal for snacks, medical supplies, and other flexible package formats. Your choice between crimp seal and fin seal should consider the desired package style, strength, and product protection needs.

Key Differences Between Crimp Seal and Fin Seal

Crimp seal and fin seal differ primarily in their sealing methods and applications; crimp seal uses interlocking teeth to create a secure closure ideal for flexible packaging needing quick resealing, while fin seal joins edges with a heat-sealed flat seam suited for continuous, high-speed production. Crimp seals provide enhanced tamper evidence and easy opening, whereas fin seals offer stronger barriers against moisture and air, improving shelf life. Understanding these key differences helps you select the appropriate sealing technology for your packaging needs, balancing durability and convenience.

Material Compatibility and Packaging Applications

Crimp seals are compatible with thicker, more rigid materials such as foil and laminated films, making them ideal for packaging heavy or solid products like coffee or snacks. Fin seals work best with flexible, heat-sealable films like polyethylene or polypropylene, suitable for lighter, moisture-sensitive items such as bakery goods or pharmaceuticals. Material compatibility significantly influences packaging application choices, ensuring product integrity and extended shelf life.

Advantages of Crimp Seal Packaging

Crimp seal packaging offers enhanced tamper resistance, ensuring product integrity and safety throughout supply chains. Its superior airtight and moisture barrier properties prolong shelf life, making it ideal for perishable goods. The packaging process is efficient and cost-effective, reducing material waste and improving production speed compared to fin seal alternatives.

Advantages of Fin Seal Packaging

Fin seal packaging offers superior strength and airtight sealing, making it ideal for preserving product freshness and extending shelf life. The design allows for efficient heat sealing on both sides, reducing the risk of leaks or contamination compared to crimp seal. You benefit from enhanced durability and consistent quality, particularly useful for packaging foods, pharmaceuticals, and other sensitive materials.

Common Industries Using Crimp and Fin Seals

Crimp seals are widely used in the food and pharmaceutical industries due to their reliable airtight packaging, which protects product freshness and prevents contamination. Fin seals are commonly found in the packaging sectors of snacks, personal care products, and chemicals, offering efficient sealing on flexible films for a streamlined production process. Your choice between crimp and fin seals depends on the specific packaging requirements and industry standards for product safety and presentation.

Factors to Consider When Choosing Between Crimp and Fin Seal

When choosing between crimp seal and fin seal, key factors include package material compatibility, sealing strength requirements, and production speed. Crimp seals offer robust mechanical strength ideal for heavy-duty packaging, while fin seals provide efficient heat sealing suitable for flexible films. Cost considerations and machine capabilities also influence the optimal sealing method for specific packaging applications.

Conclusion: Which Seal is Best for Your Product?

Choosing between crimp seal and fin seal depends on product type, packaging material, and desired shelf life. Crimp seals offer superior strength and are ideal for heavy or rigid packaging, ensuring freshness and tamper resistance. Fin seals are more efficient for lightweight, flexible packaging and offer better cost-effectiveness while maintaining adequate protection for dry goods.

Crimp seal vs fin seal Infographic

libmatt.com

libmatt.com