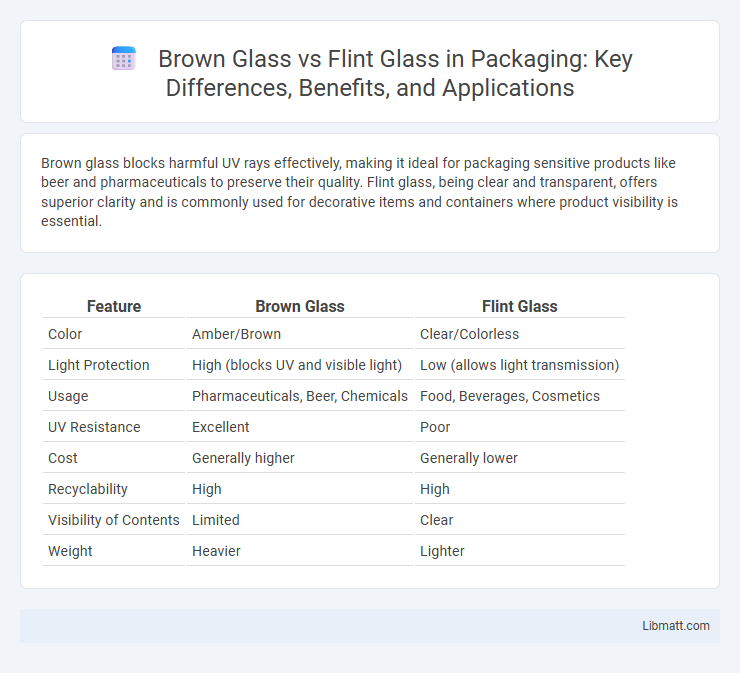

Brown glass blocks harmful UV rays effectively, making it ideal for packaging sensitive products like beer and pharmaceuticals to preserve their quality. Flint glass, being clear and transparent, offers superior clarity and is commonly used for decorative items and containers where product visibility is essential.

Table of Comparison

| Feature | Brown Glass | Flint Glass |

|---|---|---|

| Color | Amber/Brown | Clear/Colorless |

| Light Protection | High (blocks UV and visible light) | Low (allows light transmission) |

| Usage | Pharmaceuticals, Beer, Chemicals | Food, Beverages, Cosmetics |

| UV Resistance | Excellent | Poor |

| Cost | Generally higher | Generally lower |

| Recyclability | High | High |

| Visibility of Contents | Limited | Clear |

| Weight | Heavier | Lighter |

Introduction to Glass Types: Brown vs Flint

Brown glass offers superior protection from UV light, making it ideal for storing light-sensitive products like pharmaceuticals and beverages, while flint glass is clear and commonly used for decorative and everyday glassware. Brown glass is composed with higher iron content, naturally filtering out harmful rays, whereas flint glass provides excellent clarity and brilliance due to its lower impurity levels. Your choice between these glass types depends on whether product preservation or visual appeal is the primary requirement.

Chemical Composition Differences

Brown glass contains higher amounts of iron, sulfur, and carbon compounds, which contribute to its darker color and improved UV protection compared to flint glass. Flint glass is primarily composed of silica, soda ash, and lime, resulting in a clearer appearance with less UV filtering capability. Your choice between brown and flint glass should consider these chemical composition differences, especially if UV protection is essential for your application.

Light Transmission and UV Protection

Brown glass significantly reduces light transmission, blocking up to 90% of harmful ultraviolet (UV) rays, making it ideal for protecting sensitive contents from UV damage. Flint glass, on the other hand, offers high light transmission with minimal UV protection, allowing more visible light to pass through but providing less defense against UV exposure. Choosing brown glass enhances your product's longevity by preventing UV-induced degradation, while flint glass prioritizes clarity and brightness.

Common Uses in Packaging

Brown glass is commonly used in packaging for products sensitive to light, such as beer, pharmaceuticals, and certain food items, because it effectively blocks UV rays and extends shelf life. Flint glass, known for its clarity and aesthetic appeal, is typically used for packaging beverages like spirits, wine, and gourmet foods where product visibility is important. Both types of glass offer durability and recyclability but are selected based on the need for light protection versus visual presentation.

Impact on Product Shelf Life

Brown glass significantly extends product shelf life by blocking harmful UV light, which prevents oxidation and degradation of sensitive contents such as beverages, pharmaceuticals, and cosmetics. Flint glass, being clear, allows light to pass through more freely, making it less effective at protecting products from light-induced spoilage and limiting shelf life. Choosing brown glass for your packaging ensures better preservation of product quality over time.

Recyclability and Environmental Impact

Brown glass is often preferred in packaging due to its superior UV protection, which extends product shelf life and reduces waste. Both brown and flint glass are 100% recyclable, but brown glass typically requires separate collection streams to maintain color purity during recycling. Flint glass recycling processes are well-established, with higher global recycling rates that contribute to lower energy consumption and reduced carbon emissions in glass production.

Cost Comparison and Availability

Brown glass typically costs more than flint glass due to the additional materials and processes required to achieve its amber coloration, which blocks harmful UV light. Flint glass is more widely available and generally less expensive, making it a popular choice for everyday containers and packaging. Your choice between brown and flint glass will depend on budget considerations and the need for UV protection in your products.

Aesthetic and Branding Considerations

Brown glass offers a warm, vintage aesthetic that enhances brand perception by conveying quality and protection, especially for products sensitive to light such as beverages and pharmaceuticals. Flint glass, with its clear and transparent appearance, provides a sleek, modern look that showcases the product inside, appealing to brands emphasizing purity and visual appeal. Your choice between brown and flint glass should align with your branding goals, targeting either a classic, protective image or a contemporary, transparent presentation.

Industry Preferences: Pharmaceuticals, Beverages, and More

Brown glass is preferred in the pharmaceutical and beverage industries due to its superior UV protection, which helps preserve the efficacy and shelf life of light-sensitive products like medicines and certain beers. Flint glass, clear and less protective against light, is commonly used for products where clarity and color display are important, such as spirits and some non-perishable beverages. Industry choices hinge on balancing product protection against marketing appeal, with brown glass dominating in sectors prioritizing preservation.

Choosing the Right Glass for Your Needs

Brown glass offers superior protection against UV light, making it ideal for storing light-sensitive products like pharmaceuticals and beverages. Flint glass, known for its clarity and aesthetic appeal, suits applications where product visibility is crucial, such as in cosmetics or food packaging. Assess your needs for light protection versus presentation to determine whether brown or flint glass best aligns with your product requirements.

Brown glass vs flint glass Infographic

libmatt.com

libmatt.com