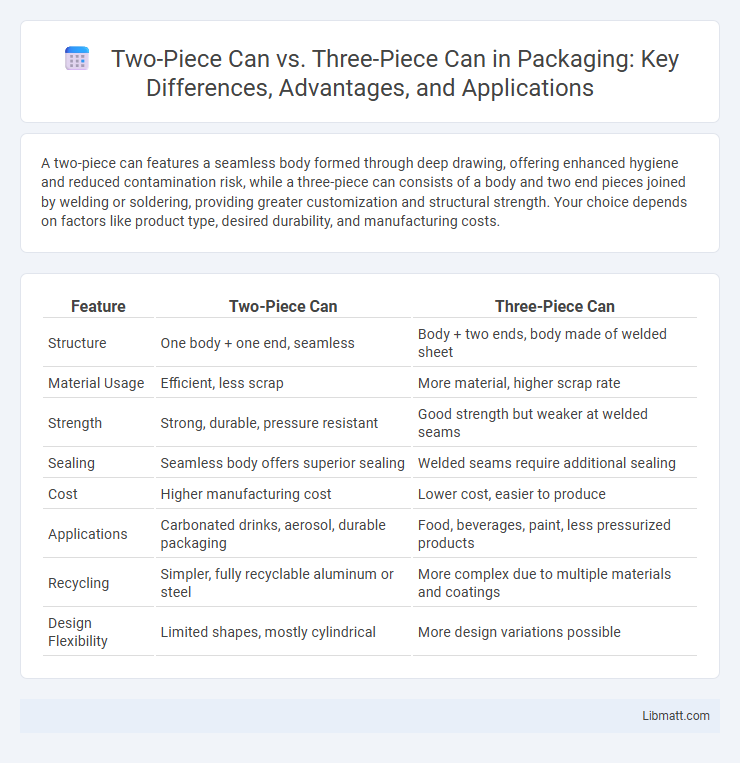

A two-piece can features a seamless body formed through deep drawing, offering enhanced hygiene and reduced contamination risk, while a three-piece can consists of a body and two end pieces joined by welding or soldering, providing greater customization and structural strength. Your choice depends on factors like product type, desired durability, and manufacturing costs.

Table of Comparison

| Feature | Two-Piece Can | Three-Piece Can |

|---|---|---|

| Structure | One body + one end, seamless | Body + two ends, body made of welded sheet |

| Material Usage | Efficient, less scrap | More material, higher scrap rate |

| Strength | Strong, durable, pressure resistant | Good strength but weaker at welded seams |

| Sealing | Seamless body offers superior sealing | Welded seams require additional sealing |

| Cost | Higher manufacturing cost | Lower cost, easier to produce |

| Applications | Carbonated drinks, aerosol, durable packaging | Food, beverages, paint, less pressurized products |

| Recycling | Simpler, fully recyclable aluminum or steel | More complex due to multiple materials and coatings |

| Design Flexibility | Limited shapes, mostly cylindrical | More design variations possible |

Introduction to Two-Piece and Three-Piece Cans

Two-piece cans consist of a seamless body and an integrated bottom, offering enhanced durability and corrosion resistance, while three-piece cans are made from three separate components: a cylindrical body and two end pieces, typically joined by welding or adhesive. Two-piece cans are commonly used for beverages and food products requiring airtight sealing, whereas three-piece cans are preferred for products needing stronger structural integrity and easier customization. Choosing your can type depends on the product's requirements for strength, shelf life, and manufacturing efficiency.

Historical Evolution of Can Manufacturing

The historical evolution of can manufacturing reveals that the two-piece can emerged as a significant innovation, simplifying production with fewer seams and reducing leakage risks compared to the earlier three-piece can design, which consisted of a cylindrical body and separate top and bottom panels. Early three-piece cans dominated the market due to easier fabrication techniques in the 19th and early 20th centuries, but advancements in metallurgy and welding technology in the mid-20th century enabled the widespread adoption of two-piece cans. Your choice between these can types depends on factors such as durability, cost, and application, with two-piece cans often preferred for their superior structural integrity and aesthetic appeal.

Structural Differences Between Two-Piece and Three-Piece Cans

Two-piece cans consist of a single body with an integral bottom formed by drawing and ironing, resulting in no side seam, which enhances corrosion resistance and reduces contamination risk. Three-piece cans are made from a cylindrical body with a separate top and bottom, joined by welded or soldered side seams that provide structural integrity but may be more prone to leakage or corrosion. Your choice between these can types depends on factors like product shelf life, manufacturing complexity, and cost efficiency related to their differing structural designs.

Manufacturing Processes Compared

Two-piece cans are manufactured through a drawing and ironing process that creates a seamless container from a single metal sheet, offering enhanced structural integrity and reduced risk of leaks. Three-piece cans involve assembling a cylindrical body from a rolled metal sheet with two separate ends welded or soldered, allowing for easier customization but introducing potential weak points at the seams. The two-piece manufacturing process is generally faster and more cost-effective for high-volume production, while three-piece cans provide greater flexibility for varying shapes and sizes.

Material and Cost Efficiency

Two-piece cans are typically made from aluminum or tinplate steel using a seamless drawing and ironing process, which reduces material waste and enhances corrosion resistance, making them cost-efficient for high-volume production. In contrast, three-piece cans consist of a cylindrical body and two end pieces welded together, using more material and labor, leading to higher manufacturing costs despite offering structural robustness. The material efficiency of two-piece cans often results in lower overall expenses, whereas three-piece cans may incur additional costs due to welding and material overlap.

Performance and Durability Analysis

Two-piece cans offer superior structural integrity due to their seamless design, reducing the risk of leakage and enhancing durability under high-pressure conditions. Three-piece cans, while easier to manufacture and customize, contain welded or sealed seams that may compromise long-term performance and increase vulnerability to corrosion. Your choice between these can types should consider specific application demands, balancing durability requirements against production efficiency.

Applications and Usage in the Packaging Industry

Two-piece cans, made through seamless drawing and ironing processes, are widely used for packaging beverages like soda and beer due to their lightweight and corrosion-resistant properties. Three-piece cans, consisting of a cylindrical body with two separate end pieces, are commonly employed for food products such as canned vegetables and soups, offering ease of customization and high-volume production. The choice between two-piece and three-piece cans depends on factors like product type, shelf life requirements, and cost-efficiency in the packaging industry.

Environmental Impact and Recyclability

Two-piece cans, made from a single continuous body and bottom, reduce the use of seam materials and often result in less waste during manufacturing compared to three-piece cans, which consist of a separate body, bottom, and lid joined by solder or adhesive. The seamless construction of two-piece cans enhances recyclability by minimizing contamination and allowing for easier metal recovery, whereas three-piece cans' layered components can complicate recycling processes. Your choice of can type influences environmental impact; selecting two-piece cans can contribute to more efficient recycling and lower resource consumption.

Advantages and Disadvantages of Each Can Type

Two-piece cans, made from a single body and bottom, offer superior corrosion resistance and a seamless design that reduces leakage risks, making them ideal for liquid packaging, but they can be more costly and less suitable for high-pressure contents. Three-piece cans consist of a cylindrical body and two separate ends, allowing cost-effective mass production and easy labeling, though their side seams may be prone to corrosion and leaks. Your choice depends on balancing the need for durability and cost-efficiency against the type of product being packaged.

Future Trends in Can Technology and Packaging

Two-piece cans, made from a single welded body and bottom, are gaining popularity due to their enhanced manufacturability and recyclability, aligning with future sustainability trends in packaging. Three-piece cans, consisting of a body and two end pieces, offer versatility in design but face challenges in reducing seams and improving environmental impact. Innovations in coatings and materials for both can types aim to extend shelf life and support circular economy goals, driving the evolution of next-generation beverage and food packaging solutions.

Two-piece can vs three-piece can Infographic

libmatt.com

libmatt.com