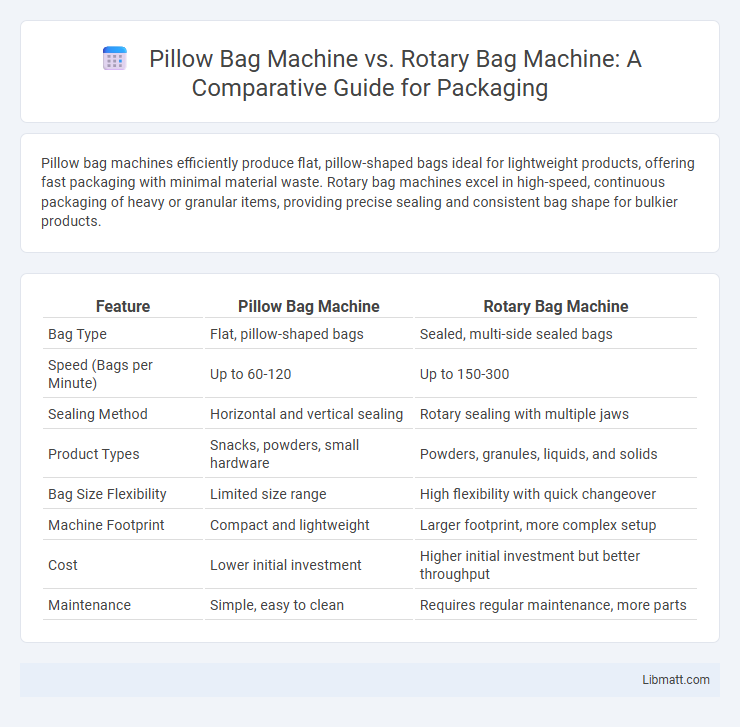

Pillow bag machines efficiently produce flat, pillow-shaped bags ideal for lightweight products, offering fast packaging with minimal material waste. Rotary bag machines excel in high-speed, continuous packaging of heavy or granular items, providing precise sealing and consistent bag shape for bulkier products.

Table of Comparison

| Feature | Pillow Bag Machine | Rotary Bag Machine |

|---|---|---|

| Bag Type | Flat, pillow-shaped bags | Sealed, multi-side sealed bags |

| Speed (Bags per Minute) | Up to 60-120 | Up to 150-300 |

| Sealing Method | Horizontal and vertical sealing | Rotary sealing with multiple jaws |

| Product Types | Snacks, powders, small hardware | Powders, granules, liquids, and solids |

| Bag Size Flexibility | Limited size range | High flexibility with quick changeover |

| Machine Footprint | Compact and lightweight | Larger footprint, more complex setup |

| Cost | Lower initial investment | Higher initial investment but better throughput |

| Maintenance | Simple, easy to clean | Requires regular maintenance, more parts |

Introduction to Pillow Bag Machines and Rotary Bag Machines

Pillow bag machines create flexible, pillow-shaped packages typically used for snacks, frozen foods, and granular products by forming, filling, and sealing film at high speeds. Rotary bag machines operate with a rotating drum mechanism to produce various bag types, offering precision for complex packaging formats such as gusseted or stand-up pouches. Both machines optimize packaging efficiency and product protection, with pillow bag machines favored for simplicity and rotary machines preferred for versatility in packaging design.

Key Features of Pillow Bag Machines

Pillow bag machines feature a compact design that enables high-speed packaging using a simple horizontal form-fill-seal process, ideal for lightweight products like snacks and powders. These machines excel in flexibility, allowing customizable bag sizes and efficient integration with automated feeding systems, which enhances production scalability. Your choice of a pillow bag machine ensures rapid operation with minimal downtime and precise sealing for consistent product freshness.

Distinct Advantages of Rotary Bag Machines

Rotary bag machines offer distinct advantages over pillow bag machines, including higher production speeds and superior precision in bag sealing and filling, which enhances overall efficiency. Their capability to handle a wide range of bag sizes and materials ensures greater versatility for diverse packaging needs. If your operation demands consistent performance and scalability, rotary bag machines provide a more advanced and reliable solution.

Packaging Applications: Pillow vs Rotary Bag Machines

Pillow bag machines excel in packaging flexible products like snacks, powders, and granular materials, creating sealed pouches with a flat, pillow-like shape that optimizes shelf space and consumer convenience. Rotary bag machines are ideal for higher-speed applications, producing complex packaging formats such as gusseted bags, stand-up pouches, and reclosable bags used in food, pharmaceutical, and industrial sectors. The choice between pillow and rotary bag machines depends on product type, packaging speed requirements, and desired bag features.

Speed and Output Comparison

Pillow bag machines typically achieve speeds ranging from 30 to 100 bags per minute, making them ideal for moderate output requirements with simpler packaging forms. Rotary bag machines offer higher speeds, often exceeding 150 bags per minute, due to continuous motion and multi-station operations, resulting in greater output efficiency for large-scale production. The choice between pillow and rotary bag machines depends on desired speed, complexity of packaging design, and production volume needs.

Material Compatibility and Flexibility

Pillow bag machines excel in handling a wide range of flexible materials such as plastic films, laminates, and paper, making them ideal for lightweight packaging needs with varying thicknesses. Rotary bag machines offer superior flexibility for different bag styles and can accommodate heavier, thicker materials including multi-layer laminates and foil, providing durability for diverse packaging requirements. Your choice depends on the material type and production needs, with pillow bag machines suited for simpler, softer materials and rotary machines designed for versatility and robust packaging.

Cost Efficiency and Investment Considerations

Pillow bag machines typically offer lower initial investment costs compared to rotary bag machines, making them ideal for small to medium-scale production with budget constraints. Rotary bag machines provide higher throughput and precision, justifying their higher cost through enhanced production capacity and reduced labor expenses over time. Evaluating production volume and long-term operational efficiency is crucial when deciding between the cost-effective pillow bag machine and the high-capacity rotary bag machine.

Space and Maintenance Requirements

Pillow bag machines require less floor space due to their compact design, making them ideal for facilities with limited room, while rotary bag machines demand a larger footprint to accommodate their rotating mechanisms. Maintenance for pillow bag machines is generally simpler and quicker, involving fewer mechanical parts compared to rotary bag machines, which have complex components requiring specialized attention and regular servicing. Choosing between the two depends on available space constraints and the capacity for ongoing maintenance resources.

Industry Adoption Trends

Pillow bag machines dominate the snack food and confectionery sectors due to their cost-effectiveness and high-speed packaging capabilities, capturing over 60% of market share in flexible packaging industries. Rotary bag machines are increasingly adopted in pharmaceutical and specialty food industries for their precision and versatility in handling complex packaging formats, showing a year-over-year growth rate of approximately 8%. Industry adoption trends indicate a strategic shift toward rotary machines for customized packaging solutions, while pillow bag machines maintain strong presence in high-volume, standardized product lines.

Choosing the Right Bag Machine for Your Needs

Pillow bag machines offer efficient, high-speed packaging for products requiring simple, flat-seal bags, making them ideal for snacks, powders, and lightweight items. Rotary bag machines excel in producing complex, gusseted, or multi-seal bags with enhanced flexibility and precision, suitable for heavier or irregularly shaped products. Understanding your product type, packaging speed, and bag design requirements ensures you select the perfect machine tailored to your production needs.

Pillow bag machine vs rotary bag machine Infographic

libmatt.com

libmatt.com