Rotary packaging machines offer higher speed and efficiency for high-volume production by continuously rotating product trays, making them ideal for complex packaging processes. Linear packaging machines are more flexible and suitable for smaller batches, providing precise control over each package as it moves along a straight line, which benefits Your customization needs.

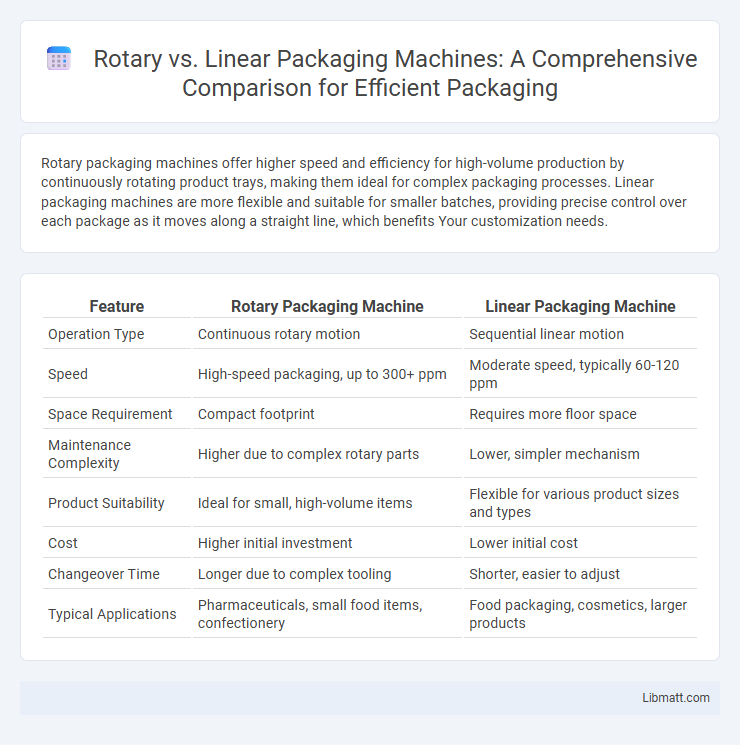

Table of Comparison

| Feature | Rotary Packaging Machine | Linear Packaging Machine |

|---|---|---|

| Operation Type | Continuous rotary motion | Sequential linear motion |

| Speed | High-speed packaging, up to 300+ ppm | Moderate speed, typically 60-120 ppm |

| Space Requirement | Compact footprint | Requires more floor space |

| Maintenance Complexity | Higher due to complex rotary parts | Lower, simpler mechanism |

| Product Suitability | Ideal for small, high-volume items | Flexible for various product sizes and types |

| Cost | Higher initial investment | Lower initial cost |

| Changeover Time | Longer due to complex tooling | Shorter, easier to adjust |

| Typical Applications | Pharmaceuticals, small food items, confectionery | Food packaging, cosmetics, larger products |

Introduction to Packaging Machines

Rotary packaging machines utilize a rotating turret to perform multiple packaging operations simultaneously, enabling high-speed production for products such as snacks, pharmaceuticals, and confectionery. Linear packaging machines operate through a sequential motion where each packaging step occurs one after another in a straight line, often preferred for simpler, lower-volume processes. The choice between rotary and linear packaging machines depends on factors like production speed, product type, and packaging complexity.

Overview of Rotary Packaging Machines

Rotary packaging machines feature a circular configuration where multiple stations perform packaging tasks simultaneously, enabling high-speed and continuous production suitable for large-scale operations. These machines excel in handling diverse product types such as food, pharmaceuticals, and consumer goods, offering precise filling, sealing, and cutting functions all within a compact footprint. Your choice of a rotary packaging machine enhances efficiency and throughput when consistent, high-volume packaging is required.

Overview of Linear Packaging Machines

Linear packaging machines feature a straightforward design where products move in a single line through various stages of packaging, enhancing precision and minimizing product damage. These machines excel in handling smaller production volumes with greater flexibility in packaging formats, making them suitable for diverse industries including food, pharmaceuticals, and cosmetics. Their modular construction allows for easy integration with other systems and swift changeovers, optimizing operational efficiency.

Key Differences Between Rotary and Linear Systems

Rotary packaging machines feature a circular design where multiple stations perform simultaneous operations, enabling higher speed and efficiency for large-scale production. Linear packaging machines operate in a straight line, with products moving sequentially through each stage, offering more flexibility for smaller batches and diverse product types. The choice between rotary and linear systems depends on production volume, product variety, and footprint requirements, with rotary excelling in high-speed applications and linear providing adaptability.

Space and Footprint Considerations

Rotary packaging machines typically require less floor space due to their compact, circular design, making them ideal for facilities with limited footprint availability. Linear packaging machines, with their extended, straight-line layout, demand more linear floor space but offer easier scalability and maintenance access. Your choice between these machines should balance available space constraints and operational workflow efficiency to maximize productivity.

Speed and Efficiency Comparison

Rotary packaging machines typically achieve higher speeds, processing up to 300 bags per minute due to their continuous motion and multi-station design, making them ideal for high-volume production. Linear packaging machines operate at slower speeds, often around 60 to 120 bags per minute, as they rely on cyclic stop-and-go movements, which can limit throughput. Efficiency in rotary machines is enhanced by reduced downtime and smoother product handling, while linear machines offer simpler maintenance but may lag in fast-paced manufacturing environments.

Flexibility and Customization Options

Rotary packaging machines offer superior flexibility with the ability to handle high-speed production and complex packaging formats, making them ideal for diverse product lines. Linear packaging machines provide customization through modular designs that allow easy adjustments for varying product sizes and packaging types. Both systems support tailored solutions but rotary machines excel in continuous operation and adaptability for multi-product runs.

Maintenance and Operation Costs

Rotary packaging machines typically incur higher maintenance costs due to their complex mechanical components and multiple moving parts, requiring specialized technicians for regular servicing. Linear packaging machines feature simpler designs that lead to lower operational and maintenance expenses, making them more cost-effective for small to medium production scales. Efficiency in maintenance and ease of operation also reduce downtime, favoring linear packaging systems in environments prioritizing cost control.

Best Applications for Rotary vs Linear Machines

Rotary packaging machines excel in high-speed, continuous processes ideal for food products, pharmaceuticals, and small consumer goods requiring precise, multi-lane packaging with superior efficiency. Linear packaging machines are best suited for intermittent operations, accommodating diverse package sizes and heavier or bulkier items such as industrial components and fresh produce. Choosing between rotary and linear packaging depends on production volume, product fragility, and packaging complexity to optimize throughput and cost-effectiveness.

Conclusion: Choosing the Right Packaging Solution

Rotary packaging machines offer high-speed, continuous motion ideal for large-scale production, while linear packaging machines provide precise control suited for smaller batches or diverse packaging formats. Your choice depends on factors like production volume, product type, and budget constraints. Selecting the right packaging solution ensures optimal efficiency, cost-effectiveness, and product integrity.

Rotary packaging machine vs linear packaging machine Infographic

libmatt.com

libmatt.com