Wet strength paper is specially treated to maintain its strength and durability when exposed to moisture, making it ideal for applications like packaging, labels, and wipes that need to withstand wet conditions. Your choice between wet strength and regular paper depends on whether the paper needs to perform in damp or wet environments, as regular paper tends to weaken and tear easily when wet.

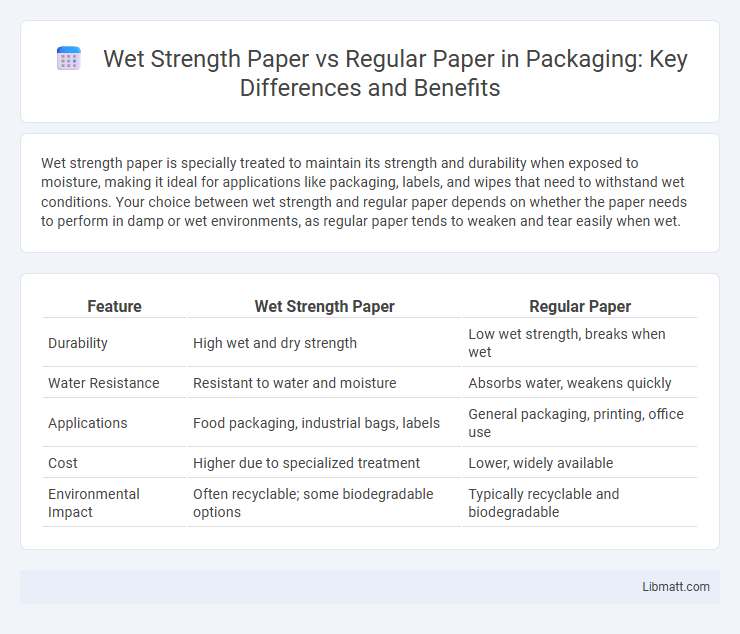

Table of Comparison

| Feature | Wet Strength Paper | Regular Paper |

|---|---|---|

| Durability | High wet and dry strength | Low wet strength, breaks when wet |

| Water Resistance | Resistant to water and moisture | Absorbs water, weakens quickly |

| Applications | Food packaging, industrial bags, labels | General packaging, printing, office use |

| Cost | Higher due to specialized treatment | Lower, widely available |

| Environmental Impact | Often recyclable; some biodegradable options | Typically recyclable and biodegradable |

Introduction to Wet Strength Paper and Regular Paper

Wet strength paper contains special additives such as wet-strength resins that significantly enhance its durability and resistance to tearing when exposed to moisture. Regular paper, composed primarily of cellulose fibers bonded without additional strengthening agents, tends to lose integrity and strength upon contact with water. The key difference lies in the chemical treatment of wet strength paper, which maintains fiber bonding under wet conditions, making it essential for applications like packaging, labels, and tissues.

Key Differences Between Wet Strength and Regular Paper

Wet strength paper contains added resins or polymers that reinforce fibers, enabling it to retain tensile strength and durability when exposed to moisture, unlike regular paper which weakens and tears easily when wet. Regular paper primarily relies on hydrogen bonds between cellulose fibers, which break down upon contact with water, leading to loss of structural integrity. Wet strength paper is commonly used in applications such as paper towels, labels, and packaging where moisture resistance is essential.

Manufacturing Process of Wet Strength Paper

Wet strength paper is produced by incorporating wet-strength resins such as polyamide-epichlorohydrin (PAE) or melamine-formaldehyde during the papermaking process, enhancing fiber bonding to resist water damage. The manufacturing involves adding these resins to the pulp slurry before sheet formation, followed by controlled drying and curing steps that reinforce the paper's structural integrity under wet conditions. This process differentiates wet strength paper from regular paper, which lacks such chemical additives and loses strength when exposed to moisture.

How Regular Paper Responds to Moisture

Regular paper absorbs moisture quickly, causing the fibers to swell and weaken, which results in a loss of structural integrity and a significant reduction in tensile strength. As the water disrupts hydrogen bonds between cellulose fibers, the paper becomes fragile, tears easily, and deforms. This response limits the usability of regular paper in humid or wet environments and for products requiring durability when exposed to moisture.

Advantages of Wet Strength Paper

Wet strength paper offers superior durability and resistance to tearing when exposed to moisture, making it ideal for applications where water or humidity is a concern. Unlike regular paper, it retains its integrity in wet conditions, ensuring your documents or packaging remain intact and legible. This enhanced performance is essential in industries like food packaging, labels, and outdoor printing, where maintaining strength and readability under wet conditions is crucial.

Common Applications of Wet Strength Paper

Wet strength paper is commonly used in applications requiring durability and resistance to moisture, such as food packaging, labels, and industrial filters. Its enhanced tensile strength makes it ideal for products exposed to water or humidity, including medical wipes and packaging for fresh produce. You can rely on wet strength paper for tasks where maintaining integrity in damp conditions is critical.

Limitations of Regular Paper in Wet Conditions

Regular paper exhibits significant limitations in wet conditions, as its cellulose fibers lose bonding strength when saturated with water, leading to rapid disintegration and reduced structural integrity. The paper's inability to resist moisture results in tearing, warping, and loss of print readability, making it unsuitable for applications requiring durability in humid or submerged environments. These inherent vulnerabilities significantly hinder regular paper's performance where moisture exposure is unavoidable.

Environmental Impact and Recyclability

Wet strength paper contains additives that enhance durability and resistance to water, making it less biodegradable and more challenging to recycle than regular paper. Regular paper, lacking these synthetic resins, breaks down more easily in natural environments and is widely accepted in standard recycling processes. Your choice impacts waste management efficiency and ecological footprint, as wet strength papers may require specialized recycling methods to minimize environmental harm.

Cost Comparison: Wet Strength vs. Regular Paper

Wet strength paper generally costs more than regular paper due to the specialized resins and additives required to enhance durability and moisture resistance. The manufacturing process for wet strength paper involves additional chemical treatments, increasing production expenses compared to standard paper. Despite the higher initial cost, wet strength paper offers better performance in applications exposed to moisture, potentially reducing replacement and damage costs over time.

Choosing the Right Paper for Your Needs

Wet strength paper offers superior durability and resistance to tearing when exposed to moisture, making it ideal for applications like packaging, labels, and outdoor use where regular paper would quickly degrade. Regular paper lacks the chemical treatments that reinforce fibers, so it is best suited for everyday printing, writing, or indoor projects where water exposure is minimal. Choosing the right paper depends on your specific requirements for strength, longevity, and environmental conditions, ensuring optimal performance without unnecessary cost.

Wet strength paper vs regular paper Infographic

libmatt.com

libmatt.com