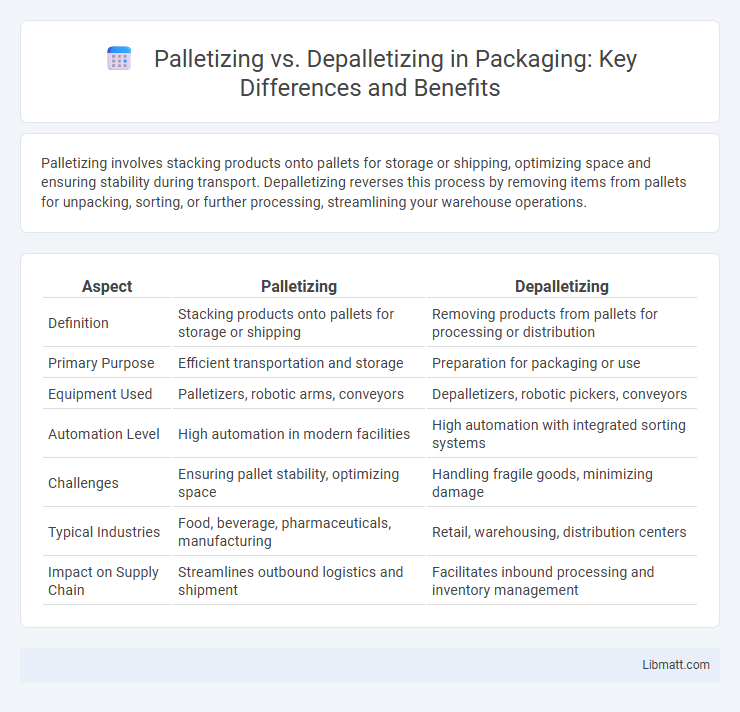

Palletizing involves stacking products onto pallets for storage or shipping, optimizing space and ensuring stability during transport. Depalletizing reverses this process by removing items from pallets for unpacking, sorting, or further processing, streamlining your warehouse operations.

Table of Comparison

| Aspect | Palletizing | Depalletizing |

|---|---|---|

| Definition | Stacking products onto pallets for storage or shipping | Removing products from pallets for processing or distribution |

| Primary Purpose | Efficient transportation and storage | Preparation for packaging or use |

| Equipment Used | Palletizers, robotic arms, conveyors | Depalletizers, robotic pickers, conveyors |

| Automation Level | High automation in modern facilities | High automation with integrated sorting systems |

| Challenges | Ensuring pallet stability, optimizing space | Handling fragile goods, minimizing damage |

| Typical Industries | Food, beverage, pharmaceuticals, manufacturing | Retail, warehousing, distribution centers |

| Impact on Supply Chain | Streamlines outbound logistics and shipment | Facilitates inbound processing and inventory management |

Introduction to Palletizing and Depalletizing

Palletizing refers to the process of stacking and organizing products onto pallets for efficient storage and transportation, while depalletizing involves the removal and unpacking of products from pallets for further processing or distribution. Both processes are essential in warehouse management and supply chain operations to optimize handling, reduce labor costs, and ensure product safety. Understanding the differences between palletizing and depalletizing can help you streamline your logistics workflow and improve overall efficiency.

Key Differences Between Palletizing and Depalletizing

Palletizing involves stacking products or materials onto a pallet in an organized manner for storage or transport, while depalletizing refers to the process of unloading items from a pallet for use or further handling. Key differences include the direction of movement--palletizing adds items to pallets, whereas depalletizing removes them--and the specific machinery designed for each task, such as robotic arms or conveyor systems optimized for stacking versus unstacking. Understanding these distinctions ensures your logistics operations efficiently manage inventory flow and reduce handling time.

Common Applications in Various Industries

Palletizing is widely used in manufacturing, warehousing, and distribution sectors for organizing products such as packaged goods, beverages, and electronics onto pallets for efficient transport. Depalletizing finds common applications in food processing, retail, and logistics industries where goods need to be unloaded from pallets for sorting, packaging, or direct customer delivery. Both processes enhance automation efficiency and streamline supply chain operations across automotive, pharmaceutical, and consumer goods industries.

Types of Palletizing Systems

Palletizing systems include robotic palletizers, which offer flexibility for various product types and sizes, and conventional palletizers, known for high-speed stacking of uniform items. Layer palletizers arrange products layer-by-layer using mechanical or robotic arms, while row palletizers place items row-by-row, optimizing space efficiency. Your choice depends on product characteristics, production volume, and required automation level to maximize operational efficiency.

Types of Depalletizing Systems

Types of depalletizing systems include robotic, gantry, and automated guided vehicle (AGV) solutions, each designed to efficiently unload products from pallets with minimal human intervention. Robotic depalletizers utilize advanced sensors and programmable arms to handle diverse product shapes and sizes, enhancing flexibility and speed in production lines. Gantry systems operate on overhead rails for precise, high-capacity handling of heavy or bulky items, while AGVs integrate autonomous navigation to transport unloaded goods seamlessly within warehouses.

Manual vs Automated Solutions

Manual palletizing relies on human labor for stacking and organizing products on pallets, which can be slower and prone to errors but allows for flexibility with varied product shapes and sizes. Automated palletizing systems utilize robotics and conveyor technology to increase speed, precision, and consistency, significantly reducing labor costs and workplace injuries. On the other hand, depalletizing involves either manual unloading of goods from pallets or automated solutions that use sensors and robotic arms to handle products safely and efficiently, optimizing material flow in warehouses.

Efficiency and Throughput Comparison

Palletizing operations typically achieve higher efficiency and throughput by automating the stacking of products onto pallets, reducing manual labor and cycle times. Depalletizing processes often face slower throughput due to the complexity of safely removing items without damage, especially with mixed or irregular loads. Advanced robotics and optimized control systems enhance both palletizing and depalletizing speeds, but palletizing generally maintains a throughput advantage in high-volume manufacturing environments.

Safety Considerations in Palletizing and Depalletizing

Safety considerations in palletizing and depalletizing center on preventing injuries from heavy lifting, equipment malfunctions, and unstable loads. Proper use of automation and robotics reduces human exposure to repetitive stress and hazardous movements, while protective gear and safety training are essential for workers handling manual operations. Ensuring compliance with OSHA standards and regularly inspecting machinery enhances workplace safety during both palletizing and depalletizing processes.

Cost and ROI Analysis

Palletizing systems typically require higher upfront investment due to complex machinery and automation technology, but they deliver faster throughput and reduced labor costs, resulting in a quicker ROI. Depalletizing equipment can be less costly initially but often involves higher manual labor expenses and slower processing speeds, potentially extending the break-even period. Evaluating operational scale, labor rates, and throughput demands is essential to determine the cost-effectiveness and profitability of palletizing versus depalletizing solutions.

Future Trends in Palletizing and Depalletizing Technologies

Future trends in palletizing and depalletizing technologies emphasize increased automation, integrating advanced robotics and AI to boost efficiency and reduce labor costs. The adoption of smart sensors and vision systems enhances precision in handling diverse products, enabling seamless adaptation to fluctuating supply chain demands. You can expect these innovations to drive greater flexibility and real-time data insights, optimizing warehouse operations and improving overall productivity.

Palletizing vs depalletizing Infographic

libmatt.com

libmatt.com