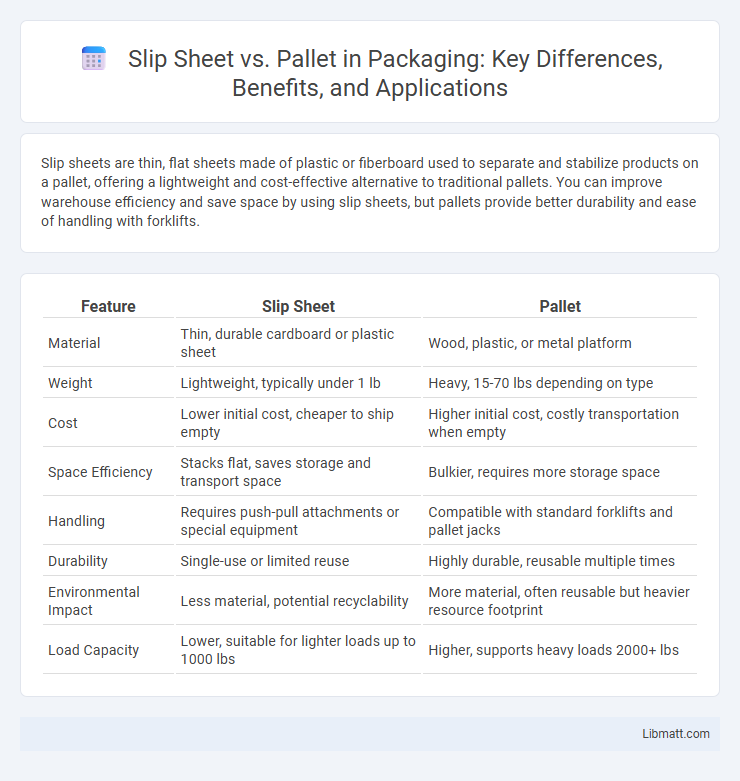

Slip sheets are thin, flat sheets made of plastic or fiberboard used to separate and stabilize products on a pallet, offering a lightweight and cost-effective alternative to traditional pallets. You can improve warehouse efficiency and save space by using slip sheets, but pallets provide better durability and ease of handling with forklifts.

Table of Comparison

| Feature | Slip Sheet | Pallet |

|---|---|---|

| Material | Thin, durable cardboard or plastic sheet | Wood, plastic, or metal platform |

| Weight | Lightweight, typically under 1 lb | Heavy, 15-70 lbs depending on type |

| Cost | Lower initial cost, cheaper to ship empty | Higher initial cost, costly transportation when empty |

| Space Efficiency | Stacks flat, saves storage and transport space | Bulkier, requires more storage space |

| Handling | Requires push-pull attachments or special equipment | Compatible with standard forklifts and pallet jacks |

| Durability | Single-use or limited reuse | Highly durable, reusable multiple times |

| Environmental Impact | Less material, potential recyclability | More material, often reusable but heavier resource footprint |

| Load Capacity | Lower, suitable for lighter loads up to 1000 lbs | Higher, supports heavy loads 2000+ lbs |

Introduction to Slip Sheets and Pallets

Slip sheets are thin, flat sheets made of corrugated fiberboard, plastic, or metal used as an alternative to pallets for unitizing loads in shipping and warehousing. Pallets, typically constructed from wood, plastic, or metal, provide a rigid platform that supports goods and facilitates handling with forklifts or pallet jacks. Slip sheets reduce transportation costs and storage space by minimizing material use and weight compared to traditional pallets.

What Are Slip Sheets?

Slip sheets are thin, flat sheets made of corrugated fiberboard, plastic, or other materials used to support and stabilize goods during transportation and storage. They serve as a cost-effective and space-saving alternative to traditional wooden pallets by allowing forklifts to lift loads with a specialized attachment called a push-pull device. Slip sheets reduce shipping volume, lower pallet disposal costs, and enhance warehouse space utilization compared to bulky pallets.

What Are Pallets?

Pallets are flat transport structures designed to support goods in a stable manner while being lifted by forklifts, pallet jacks, or conveyors. Common materials for pallets include wood, plastic, and metal, with wooden pallets dominating global logistics due to their strength and cost-effectiveness. They facilitate efficient storage, handling, and shipping, making them a fundamental component in supply chain management.

Material Composition and Design Differences

Slip sheets are typically made from corrugated fiberboard or plastic with a thin, flat design for lightweight load support, while pallets are constructed from wood, plastic, or metal, providing rigid and sturdy platforms for heavy materials. The design of slip sheets features a smooth surface with a lip for forklift or push-pull devices to grip, contrasting with pallets that have a slatted or solid deck structure enabling direct forklift tines insertion. Material composition impacts durability, cost, and weight, with slip sheets offering lower weight and cost but less protection compared to the robust and reusable nature of pallets.

Loading and Unloading Mechanisms

Slip sheets enable efficient loading and unloading through the use of specialized push-pull attachments on forklifts, reducing the need for bulky pallets and saving warehouse space. Pallets require traditional forklifts or pallet jacks to lift and move loads, which can be slower but provides more stability for heavy or irregular items. Your choice depends on balancing speed and space savings with load security during handling processes.

Cost Comparison: Slip Sheets vs Pallets

Slip sheets offer a cost-effective alternative to traditional pallets by significantly reducing material and shipping expenses due to their lightweight and compact design. Pallets typically involve higher upfront costs and increased transportation fees owing to their bulk and weight, resulting in greater fuel consumption and handling requirements. Using slip sheets can lead to substantial savings in storage space and labor costs, making them an economical choice for businesses aiming to optimize supply chain efficiency.

Space and Weight Efficiency

Slip sheets offer superior space and weight efficiency by eliminating the bulky structure of traditional pallets, allowing for more product per shipment and reducing freight costs. Pallets add extra weight and volume, which can increase shipping expenses and limit storage capacity. Choosing slip sheets maximizes cargo density and optimizes warehouse space utilization.

Environmental Impact and Sustainability

Slip sheets significantly reduce material usage compared to traditional wooden pallets, lowering deforestation and waste generation. Their lightweight design decreases transportation fuel consumption, minimizing carbon emissions and overall environmental footprint. You can enhance your supply chain's sustainability by choosing slip sheets, promoting more eco-friendly packaging solutions.

Industries and Applications

Slip sheets are widely used in the food and beverage, pharmaceuticals, and electronics industries for lightweight, space-saving shipping solutions. Pallets dominate sectors such as manufacturing, retail, and construction, providing robust support for heavy loads and facilitating forklift handling. Both materials enhance supply chain efficiency, with slip sheets optimizing container space and pallets ensuring stability in warehousing and transportation.

Choosing the Right Solution for Your Business

Slip sheets offer a lightweight, cost-effective alternative to traditional pallets, reducing shipping weight and storage space requirements significantly. Pallets provide greater durability, ease of handling with forklifts, and compatibility with automated systems, making them ideal for heavy or bulky goods. Evaluating your product type, transportation method, and warehouse infrastructure will help determine whether slip sheets or pallets best optimize your supply chain efficiency and ROI.

Slip sheet vs pallet Infographic

libmatt.com

libmatt.com