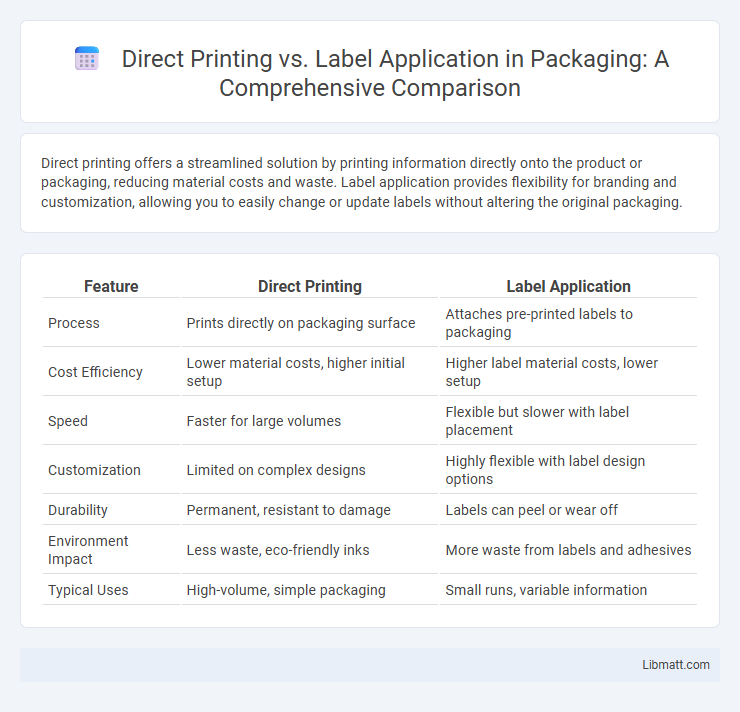

Direct printing offers a streamlined solution by printing information directly onto the product or packaging, reducing material costs and waste. Label application provides flexibility for branding and customization, allowing you to easily change or update labels without altering the original packaging.

Table of Comparison

| Feature | Direct Printing | Label Application |

|---|---|---|

| Process | Prints directly on packaging surface | Attaches pre-printed labels to packaging |

| Cost Efficiency | Lower material costs, higher initial setup | Higher label material costs, lower setup |

| Speed | Faster for large volumes | Flexible but slower with label placement |

| Customization | Limited on complex designs | Highly flexible with label design options |

| Durability | Permanent, resistant to damage | Labels can peel or wear off |

| Environment Impact | Less waste, eco-friendly inks | More waste from labels and adhesives |

| Typical Uses | High-volume, simple packaging | Small runs, variable information |

Introduction to Direct Printing and Label Application

Direct printing uses inkjet or laser technology to apply images directly onto products, offering a seamless and efficient coding solution. Label application involves printing information on adhesive labels, which are then affixed to products, providing flexibility for variable data and different surface types. Understanding these differences helps you choose the best method for your packaging and branding needs.

Defining Direct Printing: Methods and Use Cases

Direct printing involves applying ink or toner directly onto a product's surface using methods like thermal transfer, inkjet, or laser printing, suitable for coding barcodes, expiration dates, or batch numbers. This technique eliminates the need for labels, reducing material costs and waste, and is ideal for high-speed production lines in industries such as food, pharmaceuticals, and electronics. Your choice of direct printing depends on factors like substrate type, durability requirements, and production volume to ensure optimal results.

Understanding Label Application: Types and Processes

Label application involves various methods such as pressure-sensitive, hot melt, and cold glue techniques, each suited for different labeling needs and materials. Pressure-sensitive labels use adhesive backing for quick, versatile application, while hot melt and cold glue methods provide durable bonds for heavy-duty products. Understanding these processes helps select the optimal labeling approach, ensuring label durability and alignment with product requirements.

Cost Comparison: Direct Printing vs Label Application

Direct printing typically reduces material costs by eliminating the need for separate labels and adhesives, which can represent significant expenses in label application processes. While initial investment in direct printing equipment may be higher, the overall cost per unit decreases due to faster production times and lower waste generation. In contrast, label application incurs ongoing expenses related to label procurement, storage, and labor for application, potentially increasing total operational costs over time.

Speed and Efficiency: Which is Faster?

Direct printing offers faster production speeds by eliminating the need for separate label creation and application steps, streamlining the entire process. Label application involves additional handling time to print, peel, and affix labels, which can slow down overall throughput. For high-volume operations requiring rapid turnaround, direct printing delivers superior efficiency and reduced downtime.

Durability and Print Quality Differences

Direct printing uses ink or toner applied directly to the product surface, offering high-resolution images but potentially lower durability on rough or flexible materials. Label application involves printing on adhesive-backed materials, providing enhanced protection through lamination or coating, resulting in superior resistance to abrasion, chemicals, and moisture. While direct printing excels in sharpness and detail for short-term uses, label application ensures long-lasting durability and consistent print quality in harsh environments.

Flexibility in Design and Material Compatibility

Direct printing offers high flexibility in design by enabling precise, customizable graphics directly on various substrate surfaces, whereas label application is limited by the predefined dimensions and shapes of labels. Material compatibility favors direct printing for substrates like plastics, metals, and glass, while label application accommodates materials unsuited for direct ink adhesion, including irregular or rough surfaces. Both methods support tailored designs, but direct printing excels in seamless integration and durability on smooth, printable materials.

Environmental Impact and Sustainability Considerations

Direct printing reduces waste by eliminating the need for labels and adhesives, thus minimizing plastic and paper consumption. Labels often involve additional materials such as adhesives and backing liners, which contribute to landfill waste and complicate recycling efforts. Choosing direct printing supports sustainability goals by lowering resource use and improving recyclability of packaging materials.

Industry-Specific Applications and Preferences

Direct printing is preferred in industries requiring high-speed, on-demand labeling such as pharmaceuticals and food packaging, where variable data and Batch traceability are crucial. Label application suits sectors like logistics and retail, offering flexibility for diverse packaging shapes and compliance labels with pre-printed graphics. Both methods optimize productivity and accuracy, with choices driven by industry standards, cost-efficiency, and product handling needs.

Choosing the Right Solution: Key Decision Factors

Selecting between direct printing and label application depends on factors such as production volume, operational costs, and material compatibility. Direct printing offers fast, contactless marking ideal for high-speed manufacturing lines, while label application provides flexibility for variable data and complex graphics. You should evaluate durability requirements, printer maintenance, and substrate type to determine the most efficient and cost-effective solution for your labeling needs.

Direct printing vs label application Infographic

libmatt.com

libmatt.com