Extrusion coating involves applying a molten polymer directly onto a substrate, creating a strong, flexible barrier ideal for packaging and industrial uses. Lamination bonds multiple layers of materials using adhesives or heat, enhancing durability, appearance, and resistance to moisture and chemicals, which can improve your product's overall performance.

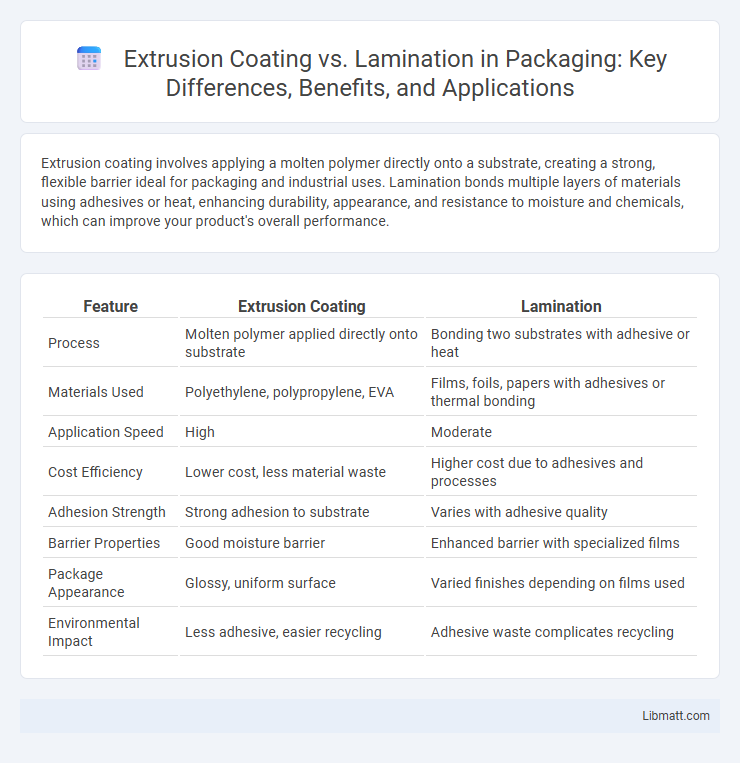

Table of Comparison

| Feature | Extrusion Coating | Lamination |

|---|---|---|

| Process | Molten polymer applied directly onto substrate | Bonding two substrates with adhesive or heat |

| Materials Used | Polyethylene, polypropylene, EVA | Films, foils, papers with adhesives or thermal bonding |

| Application Speed | High | Moderate |

| Cost Efficiency | Lower cost, less material waste | Higher cost due to adhesives and processes |

| Adhesion Strength | Strong adhesion to substrate | Varies with adhesive quality |

| Barrier Properties | Good moisture barrier | Enhanced barrier with specialized films |

| Package Appearance | Glossy, uniform surface | Varied finishes depending on films used |

| Environmental Impact | Less adhesive, easier recycling | Adhesive waste complicates recycling |

Introduction to Extrusion Coating and Lamination

Extrusion coating involves applying a molten polymer layer directly onto a substrate to create a strong, uniform bond, enhancing water resistance and durability. Lamination combines two or more layers of materials bonded by adhesives or heat to improve strength, appearance, and barrier properties. Understanding these processes helps you select the right technique for packaging, printing, or industrial applications based on performance and cost efficiency.

Understanding the Extrusion Coating Process

Extrusion coating involves applying a molten polymer layer directly onto a substrate, creating a strong bond upon cooling that enhances moisture resistance and mechanical strength. This process utilizes materials such as polyethylene or polypropylene, which solidify rapidly to form a uniform coating without the need for adhesives. Unlike lamination, which joins two distinct layers via adhesives or heat, extrusion coating integrates the coating material seamlessly, offering superior protection and durability for packaging applications.

Overview of Lamination Techniques

Lamination techniques include adhesive lamination, extrusion lamination, and solventless lamination, each offering distinct advantages based on the materials and applications involved. Extrusion lamination involves applying a melted polymer layer to bond substrates, providing excellent moisture barriers and enhanced strength, while adhesive lamination uses a glue layer for flexible and multi-material combinations. Your choice between extrusion coating and lamination depends on factors such as material compatibility, desired durability, and cost efficiency.

Key Differences Between Extrusion Coating and Lamination

Extrusion coating involves applying a molten polymer layer directly onto a substrate, creating a strong bond through heat and pressure, while lamination combines two or more layers using adhesives or heat to form a composite material. Extrusion coating typically provides superior moisture resistance and enhanced barrier properties compared to lamination, making it ideal for packaging applications requiring durability. Your choice hinges on specific product needs, with extrusion coating favored for seamless, protective layers and lamination preferred for combining varied materials with distinct functions.

Material Compatibility and Selection

Extrusion coating excels in bonding thermoplastic materials such as polyethylene and polypropylene to various substrates, offering strong adhesion on paper, foil, and plastics. Lamination provides greater material compatibility by combining diverse films, foils, and paper layers using adhesives, ideal for substrates that are sensitive to heat or require specific barrier properties. Material selection depends on substrate sensitivity, desired barrier performance, and the mechanical strength required for the final product, with extrusion coating favored for single-layer thermoplastic bonding and lamination preferred for multi-layer composite structures.

Performance and Applications in Packaging

Extrusion coating offers superior moisture resistance and excellent adhesion to a variety of substrates, making it ideal for flexible packaging such as food wrappers and pharmaceutical pouches. Lamination provides enhanced barrier properties, durability, and improved mechanical strength, which suits packaging applications requiring multi-layer protection like liquid cartons and medical device packaging. Your choice between extrusion coating and lamination depends on the desired balance of performance characteristics and specific packaging requirements.

Cost Comparison: Extrusion Coating vs Lamination

Extrusion coating generally offers a more cost-effective solution compared to lamination due to lower material and processing expenses, making it ideal for high-volume production runs. Lamination, while potentially higher in initial costs due to adhesive use and more complex machinery, provides superior durability and aesthetic finishes that may justify the investment for premium packaging. You should balance budget constraints with the desired product performance when choosing between extrusion coating and lamination.

Environmental Impact and Sustainability Considerations

Extrusion coating typically uses a single polymer layer, such as polyethylene, allowing easier recycling but producing higher energy consumption during processing compared to lamination, which combines multiple materials and adhesives that can complicate recycling efforts. Lamination often incorporates eco-friendly adhesives and can reduce plastic usage by enabling thinner films, but mixed-material layers pose challenges for waste separation and biodegradability. Assess Your choice based on the balance between recyclability and overall lifecycle environmental impact to support sustainable packaging solutions.

Quality Control and Testing Methods

Extrusion coating involves applying a molten polymer layer directly onto a substrate, requiring rigorous viscosity and temperature monitoring to ensure uniform thickness and adhesion, while lamination bonds multiple layers with adhesives or heat, necessitating peel strength and delamination resistance testing. Quality control in extrusion coating emphasizes melt flow index and surface tension evaluations, whereas lamination processes focus on cohesive bond integrity, thermal resistance, and flexibility assessments. Your choice between extrusion coating and lamination should consider the specific testing methods that best guarantee product durability and performance in the final application.

Choosing the Right Process for Your Application

Extrusion coating offers a cost-effective and durable solution by applying a molten polymer layer directly onto substrates, making it ideal for moisture barriers and flexible packaging. Lamination combines two or more substrates with adhesives or heat, providing enhanced aesthetics, strength, and protection for applications requiring multi-material bonding. Your choice depends on factors like desired barrier properties, product durability, and budget constraints to ensure optimal performance for your specific application.

Extrusion coating vs lamination Infographic

libmatt.com

libmatt.com