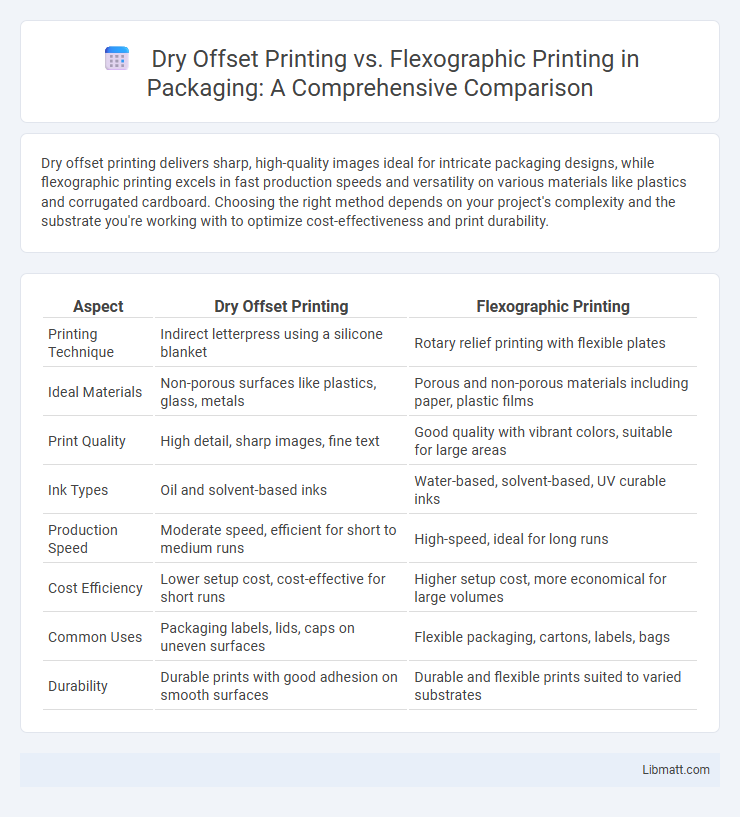

Dry offset printing delivers sharp, high-quality images ideal for intricate packaging designs, while flexographic printing excels in fast production speeds and versatility on various materials like plastics and corrugated cardboard. Choosing the right method depends on your project's complexity and the substrate you're working with to optimize cost-effectiveness and print durability.

Table of Comparison

| Aspect | Dry Offset Printing | Flexographic Printing |

|---|---|---|

| Printing Technique | Indirect letterpress using a silicone blanket | Rotary relief printing with flexible plates |

| Ideal Materials | Non-porous surfaces like plastics, glass, metals | Porous and non-porous materials including paper, plastic films |

| Print Quality | High detail, sharp images, fine text | Good quality with vibrant colors, suitable for large areas |

| Ink Types | Oil and solvent-based inks | Water-based, solvent-based, UV curable inks |

| Production Speed | Moderate speed, efficient for short to medium runs | High-speed, ideal for long runs |

| Cost Efficiency | Lower setup cost, cost-effective for short runs | Higher setup cost, more economical for large volumes |

| Common Uses | Packaging labels, lids, caps on uneven surfaces | Flexible packaging, cartons, labels, bags |

| Durability | Durable prints with good adhesion on smooth surfaces | Durable and flexible prints suited to varied substrates |

Introduction to Dry Offset and Flexographic Printing

Dry offset printing utilizes a rubber blanket to transfer ink from a plate to the substrate, enabling high-speed and precise printing on curved surfaces such as cans and bottles. Flexographic printing employs flexible relief plates and fast-drying inks, ideal for packaging materials like plastic, paper, and foils due to its adaptability and cost-efficiency. Both methods serve distinct roles in commercial printing, with dry offset excelling in metal and glass decoration, while flexography dominates flexible packaging and label production.

Core Principles of Dry Offset Printing

Dry offset printing operates by transferring ink from a plate to a silicone blanket before applying it onto the substrate, ensuring high precision and smooth image quality. This technique utilizes oil-based inks and a hydrophobic plate surface to repel water, enabling sharp, detailed images ideal for metal and plastic surfaces. The core principle revolves around indirect image transfer, which minimizes plate wear and enhances print durability compared to direct printing methods like flexography.

Core Principles of Flexographic Printing

Flexographic printing operates on the core principle of using flexible relief plates made from rubber or photopolymer, which transfer ink directly onto various substrates through a rotary press. Unlike dry offset printing, flexography employs fast-drying, low-viscosity inks suitable for high-speed, continuous runs on materials like plastic, foil, and corrugated cardboard. Your choice of flexographic printing ensures efficient production with vibrant colors and excellent durability for packaging and labeling applications.

Key Differences in Printing Process

Dry offset printing utilizes a waterless lithographic process, transferring ink from a plate to a rubber blanket and then onto the substrate, allowing for high-resolution images with less ink waste. Flexographic printing employs flexible relief plates and fast-drying liquid inks, ideal for printing on uneven surfaces and packaging materials with quick turnaround times. The key difference lies in dry offset's dry ink transfer method versus flexography's direct, high-speed plate contact process, impacting print quality and substrate compatibility.

Substrate Compatibility and Applications

Dry offset printing excels in high-precision printing on non-porous substrates like metal cans, glass, and plastic, making it ideal for beverage containers and promotional items. Flexographic printing offers superior versatility across various porous and non-porous materials, including paper, cardboard, plastic films, and foil, commonly used in packaging, labels, and flexible materials. Your choice depends on the substrate's surface and the intended application, with dry offset preferred for smooth, hard surfaces and flexographic favored for diverse, flexible packaging solutions.

Print Quality Comparison

Dry offset printing offers superior print quality with finer detail and richer color density, making it ideal for packaging requiring high-resolution images and sharp text. Flexographic printing provides fast production rates and versatile substrate compatibility but generally produces less precise and slightly muted print results. The choice between the two methods often hinges on the demand for crispness and color fidelity versus cost-efficiency and speed.

Ink Types and Environmental Impact

Dry offset printing utilizes oil-based inks that offer high durability and vibrant colors but can release volatile organic compounds (VOCs), impacting air quality. Flexographic printing employs water-based or UV-curable inks, significantly reducing VOC emissions and environmental hazards. The choice between these methods influences sustainability efforts, with flexography generally providing a greener solution due to its eco-friendly ink formulations.

Production Speed and Efficiency

Dry offset printing offers faster production speeds for medium to high-volume runs due to its quick setup and rapid ink drying process, making it highly efficient for printing on irregular or cylindrical surfaces. Flexographic printing excels in high-speed, long-run projects with its ability to handle large volumes continuously while maintaining consistent print quality on various substrates including plastics, paper, and metallic films. Production efficiency in flexography is enhanced by automated plate changing and minimal waste generation, which reduces downtime and operational costs.

Cost Analysis: Dry Offset vs Flexography

Dry offset printing generally incurs higher initial setup costs due to its specialized plates and intricate image transfer process, making it less cost-effective for large print runs. Flexographic printing offers lower setup expenses and faster turnaround times, resulting in reduced overall production costs, especially for high-volume jobs. Your choice depends on balancing quality requirements and budget constraints, with flexography favored for economical large-scale printing.

Choosing the Right Printing Method

Choosing between dry offset printing and flexographic printing depends on your project requirements such as print quality, substrate type, and production volume. Dry offset printing excels in producing sharp, detailed images on non-porous surfaces like metal and plastic, making it ideal for high-quality packaging labels. Flexographic printing offers faster setup and cost efficiency on flexible materials like paper, film, and foil, suited for large runs and continuous patterns.

Dry offset printing vs flexographic printing Infographic

libmatt.com

libmatt.com