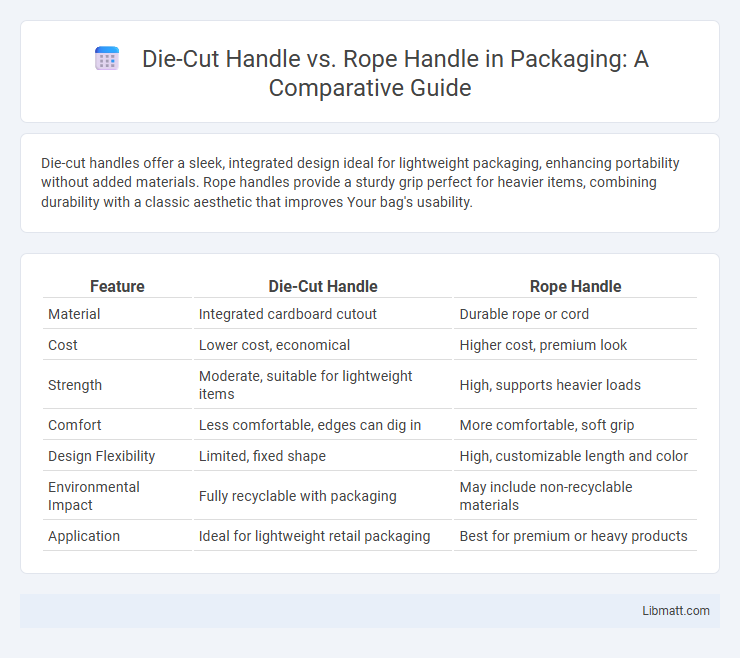

Die-cut handles offer a sleek, integrated design ideal for lightweight packaging, enhancing portability without added materials. Rope handles provide a sturdy grip perfect for heavier items, combining durability with a classic aesthetic that improves Your bag's usability.

Table of Comparison

| Feature | Die-Cut Handle | Rope Handle |

|---|---|---|

| Material | Integrated cardboard cutout | Durable rope or cord |

| Cost | Lower cost, economical | Higher cost, premium look |

| Strength | Moderate, suitable for lightweight items | High, supports heavier loads |

| Comfort | Less comfortable, edges can dig in | More comfortable, soft grip |

| Design Flexibility | Limited, fixed shape | High, customizable length and color |

| Environmental Impact | Fully recyclable with packaging | May include non-recyclable materials |

| Application | Ideal for lightweight retail packaging | Best for premium or heavy products |

Introduction to Handle Types: Die-cut vs Rope

Die-cut handles are integrated directly into the bag, offering a sleek and cost-effective design ideal for lightweight to medium loads, while rope handles provide enhanced durability and comfort, suitable for heavier items and premium packaging. Your choice depends on the balance between budget, aesthetics, and functionality, as die-cut handles excel in streamlined looks and rope handles in sturdy grip. Understanding these key differences helps optimize bag usability and brand presentation.

Material Selection for Handles

Material selection for die-cut handles typically involves sturdy cardboard or paperboard, ensuring durability while maintaining cost-effectiveness, ideal for lightweight to moderate loads. Rope handles are often crafted from cotton, nylon, or jute, offering enhanced comfort and strength for heavier or premium packaging needs. Your choice should balance the desired handle strength, handle aesthetics, and overall bag durability to optimize customer experience and brand perception.

Design Aesthetics: Visual Appeal Comparison

Die-cut handles offer a sleek, modern look with clean, precise edges that enhance minimalistic design aesthetics. Rope handles provide a textured, natural appearance that adds a tactile, premium feel to packaging, often complementing eco-friendly or rustic themes. Your choice between die-cut and rope handles should align with the desired visual impact and brand personality to maximize appeal.

Durability and Strength Analysis

Die-cut handles offer moderate durability, ideal for lightweight products, but are prone to tearing under heavy loads due to their integrated design in the bag material. Rope handles provide superior strength and longevity, as they are typically made from twisted cotton, nylon, or polyester, ensuring better weight distribution and resistance to breakage. Choosing rope handles for your packaging guarantees enhanced durability, especially when carrying heavier or bulkier items.

Carrying Comfort and Ergonomics

Die-cut handles offer a lightweight grip that integrates seamlessly into bag designs, reducing bulk and providing a smooth, flat surface ideal for short-term carrying. Rope handles, often padded or coated, deliver enhanced comfort for extended use by distributing weight evenly and reducing strain on the hands. Ergonomically, rope handles better accommodate diverse hand sizes and improve grip security, making them preferable for heavier loads or prolonged carrying.

Cost Implications: Production and Customization

Die-cut handles typically incur lower production costs due to simpler manufacturing processes and minimal material use, making them a budget-friendly choice for standard packaging. Rope handles offer greater customization options and a premium look but involve higher expenses in both materials and labor, increasing overall production costs. Your decision should balance cost implications against the desired aesthetic and functional appeal of the package.

Environmental Impact and Sustainability

Die-cut handles produce less waste during manufacturing compared to rope handles, which require additional materials and energy to produce and attach. Your choice of die-cut handles can reduce plastic consumption and improve recyclability, as these handles are typically integrated into the packaging itself. Rope handles, often made from synthetic fibers, have a higher carbon footprint and may complicate recycling processes, making die-cut handles a more sustainable option.

Brand Perception and Marketing Value

Die-cut handles convey a minimalist and modern brand perception ideal for eco-friendly and premium packaging, enhancing marketing value through sleek design and cost-efficiency. Rope handles elevate brand perception by adding a tactile, luxury feel, often associated with high-end products, thereby increasing perceived value and customer retention. Choosing between die-cut and rope handles depends on target audience preferences and the desired brand positioning in competitive markets.

Best Use Cases for Each Handle Type

Die-cut handles are best suited for lightweight packaging such as retail bags, promotional materials, and food containers where cost efficiency and sleek design are priorities. Rope handles provide superior durability and comfort, ideal for heavier items like apparel, gift boxes, and luxury shopping bags that require enhanced support for carrying. Understanding your product weight and customer experience will help you choose the most effective handle type for your packaging needs.

Choosing the Right Handle for Your Packaging

Selecting the right handle for your packaging depends on factors like durability, aesthetics, and user comfort. Die-cut handles offer a sleek, integrated look suitable for lightweight products, while rope handles provide strength and a premium feel for heavier items. Consider the product weight, brand image, and customer experience to determine whether die-cut or rope handles best enhance your packaging functionality and appeal.

Die-cut handle vs rope handle Infographic

libmatt.com

libmatt.com