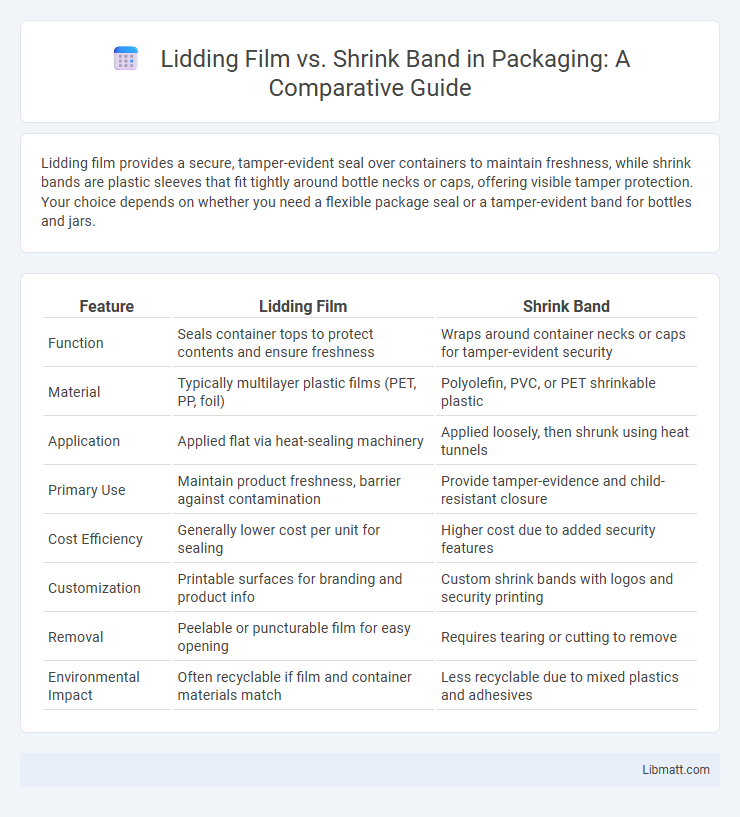

Lidding film provides a secure, tamper-evident seal over containers to maintain freshness, while shrink bands are plastic sleeves that fit tightly around bottle necks or caps, offering visible tamper protection. Your choice depends on whether you need a flexible package seal or a tamper-evident band for bottles and jars.

Table of Comparison

| Feature | Lidding Film | Shrink Band |

|---|---|---|

| Function | Seals container tops to protect contents and ensure freshness | Wraps around container necks or caps for tamper-evident security |

| Material | Typically multilayer plastic films (PET, PP, foil) | Polyolefin, PVC, or PET shrinkable plastic |

| Application | Applied flat via heat-sealing machinery | Applied loosely, then shrunk using heat tunnels |

| Primary Use | Maintain product freshness, barrier against contamination | Provide tamper-evidence and child-resistant closure |

| Cost Efficiency | Generally lower cost per unit for sealing | Higher cost due to added security features |

| Customization | Printable surfaces for branding and product info | Custom shrink bands with logos and security printing |

| Removal | Peelable or puncturable film for easy opening | Requires tearing or cutting to remove |

| Environmental Impact | Often recyclable if film and container materials match | Less recyclable due to mixed plastics and adhesives |

Introduction to Lidding Film and Shrink Bands

Lidding film and shrink bands serve distinct purposes in packaging, with lidding film primarily sealing containers for freshness and protection, while shrink bands provide tamper-evident security by tightly wrapping around product openings. Lidding films are typically made from materials like polyethylene or polypropylene and offer barrier properties against moisture and contaminants. Shrink bands, often composed of PVC or PET, shrink under heat to form a secure seal, ensuring product integrity until the consumer opens the package.

Key Differences Between Lidding Film and Shrink Bands

Lidding film offers a flat sealing solution ideal for containers requiring airtight closure, while shrink bands provide tamper-evident security by conforming tightly around container openings after heat application. Your choice depends on whether you prioritize sealing integrity or tamper-evidence, as lidding films emphasize barrier properties and ease of opening, whereas shrink bands ensure protection against contamination and unauthorized access. Material composition also differs, with lidding films typically made from laminate plastics and shrink bands from heat-shrinkable polymers like PVC or PET for flexibility and shrinkage.

Material Composition and Structure

Lidding film typically consists of multi-layered materials such as aluminum foil, polyethylene, and polyester that provide excellent barrier properties and sealing capabilities, making it ideal for preserving food freshness. In contrast, shrink bands are usually made from heat-sensitive polymers like PVC or PET, which shrink tightly around the product when heated, ensuring tamper-evidence and secure packaging. Your choice between these two depends on whether you prioritize product protection through sealing or tamper-evident security.

Application Processes and Techniques

Lidding film involves heat sealing a pre-cut film over containers to create an airtight seal, commonly used in food and pharmaceutical packaging for tamper evidence and freshness preservation. Shrink bands are applied by placing a plastic sleeve over the container's closure, then using heat to shrink the band tightly around the neck, providing a secure tamper-evident seal. Your choice between lidding film and shrink band depends on the packaging line speed, container type, and desired level of protection and consumer convenience.

Seal Integrity and Tamper Evidence

Lidding film provides superior seal integrity by creating a strong, airtight barrier that protects product freshness and prevents contamination. Shrink bands offer clear tamper evidence by securely encasing the container's closure, making any unauthorized access immediately visible. Your choice between lidding film and shrink band should prioritize whether maintaining airtight protection or ensuring tamper-proof security is most critical for your packaging needs.

Customization and Branding Opportunities

Lidding film offers extensive customization options with vibrant printing capabilities, allowing brands to enhance product visibility and convey detailed information directly on the seal. Shrink bands provide flexible branding opportunities by conforming to container shapes, enabling 360-degree graphics that increase shelf impact and tamper evidence. Both packaging solutions support unique brand identities but differ in material use and application methods, influencing the choice based on marketing and functional needs.

Cost Comparison and Efficiency

Lidding film offers a lower cost solution compared to shrink bands due to reduced material usage and faster application processes, enhancing overall production efficiency. Shrink bands provide superior tamper-evidence and product protection but require higher energy consumption and longer application times, increasing operational costs. Evaluating packaging needs against budget constraints determines the optimal balance between cost-effectiveness and functional efficiency in selecting lidding films or shrink bands.

Environmental Impact and Sustainability

Lidding films often contain multilayer plastics that make recycling challenging and contribute to landfill waste, whereas shrink bands typically use single-material polyethylene, enhancing recyclability and reducing environmental footprint. The production energy and carbon emissions for shrink bands are generally lower due to simpler manufacturing processes and materials. Choosing shrink bands over lidding films supports sustainability goals by minimizing plastic waste and promoting circular economy practices within packaging industries.

Industry-Specific Use Cases

Lidding film is widely used in the food and beverage industry to provide airtight seals for containers, ensuring product freshness and preventing contamination. Shrink bands are prevalent in pharmaceuticals and cosmetics for tamper evidence, offering a visible security layer that protects Your products from tampering during distribution. Each packaging solution serves distinct industry needs, with lidding film catering to sealing and freshness, while shrink bands emphasize protection and product integrity.

Choosing the Right Packaging Solution for Your Product

Choosing the right packaging solution depends on product protection and marketing needs; lidding films provide airtight seals ideal for food freshness and tamper evidence, while shrink bands offer 360-degree tamper resistance and visual appeal. Consider material compatibility, sealing methods, and cost efficiency when selecting between lidding film and shrink bands to ensure product integrity and consumer trust. Optimizing packaging choice enhances shelf life, brand visibility, and regulatory compliance in packaged goods.

Lidding film vs shrink band Infographic

libmatt.com

libmatt.com